Multi-gear Hybrid Drive System Based on Planetary Gear Train

A planetary gear train and drive system technology, applied in the field of multi-gear hybrid drive system, can solve the problems of few gears, large volume and weight of engine and motor, low working efficiency of engine and motor, etc. The effect of high power and energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Best practice:

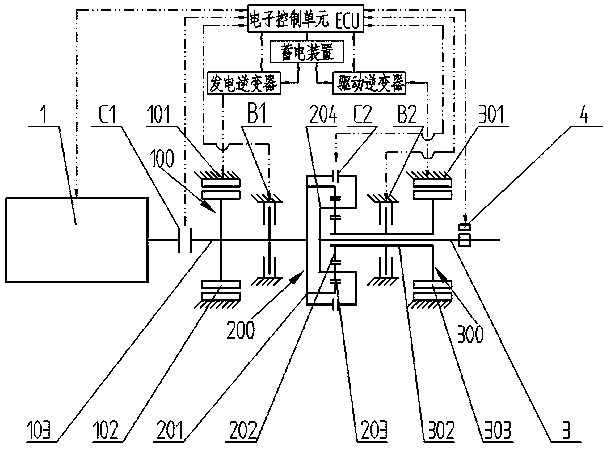

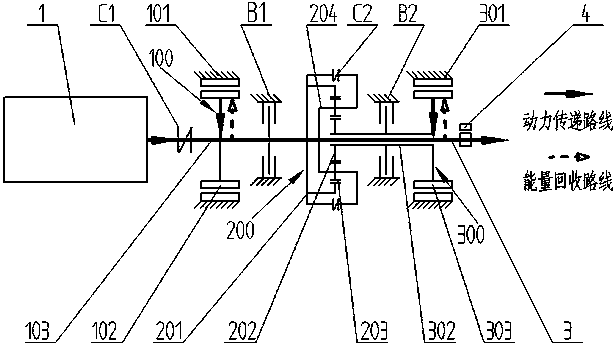

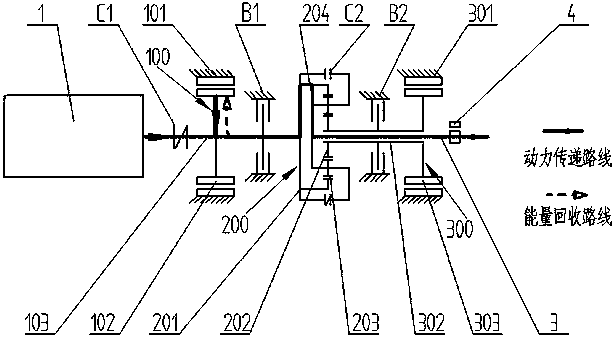

[0048] Refer to attached figure 1 , a multi-gear hybrid drive system based on a planetary gear train, including an engine 1, a first clutch C1, a generator 100, a first brake B1, a planetary gear train 200, a second clutch C2, a drive motor 300, and a second brake B2, the power output shaft 3, the rotational speed sensor 4, the electronic control unit ECU, the power generation inverter, the driving inverter and the power storage device constitute a multi-gear hybrid drive system coupled with variable speed. The drive system includes three power sources: engine 1, generator motor 100, drive motor 300; four friction elements: first clutch C1, first brake B1, second clutch C2, second brake B2; Three planetary system rotation elements: ring gear 201 , sun gear 202 , and planetary carrier 204 . The engine 1 is connected or disconnected in series with the generator 100 through the engagement or disconnection of the first clutch C1; the inner hub of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com