Production process for preparing mung bean yeast

A production process, mung bean koji technology, applied in the field of koji making, can solve the problems of rarely used and high production costs, and achieve the effect of increasing the flavor of mung bean and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

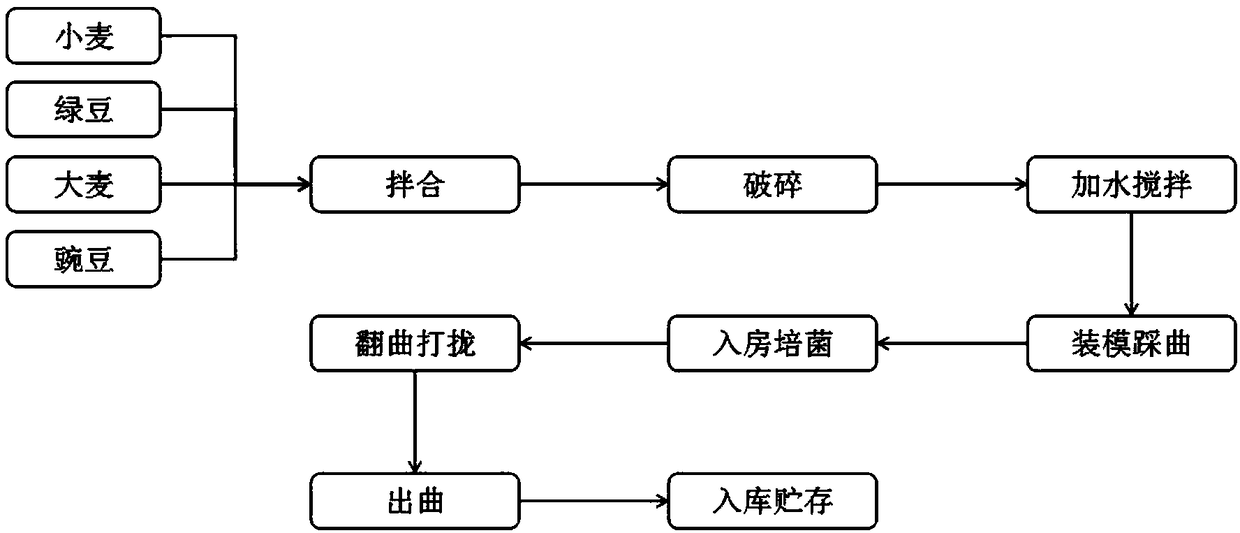

[0052] See figure 1 As shown, the present invention is a production process for preparing mung bean koji. The raw materials for preparing mung bean koji are: wheat, mung bean, barley, and peas, and the weight percentages are respectively: wheat 40%, mung bean 20%, barley 5%, and peas 35 %; The grade rate of the first-class products of Qu reaches 50.5%.

Embodiment 2

[0054] See figure 1 As shown, the present invention is a production process for preparing mung bean koji. The raw materials for preparing mung bean koji are: wheat, mung bean, barley, and peas, and the weight percentages are respectively: wheat 49%, mung bean 29%, barley 9%, and peas 13 %; The grade rate of the first-class products of Qu reached 61.5%.

Embodiment 3

[0056] See figure 1 As shown, the present invention is a production process for preparing mung bean koji. The raw materials for preparing mung bean koji are: wheat, mung bean, barley, and peas, and the weight percentages are respectively: wheat 45%, mung bean 25%, barley 7%, and peas 23 %; The grade rate of the first-class products of Qu reaches 70.5%.

[0057] The method steps for preparing mung bean koji are:

[0058] Step one, mixing

[0059] Before mixing the raw materials, add 3.5% to 5% of the raw material mass with a temperature gradient of 45℃-69℃-62℃ hydrating material, then mix and mix evenly, and gather the accumulation of hydrating material for 40-50min;

[0060] Step two, broken

[0061] Crush the medium temperature koji obtained after mixing in step 1 and pass through a 30-mesh sieve;

[0062] Step three, add water and stir

[0063] Infuse the material sieved in step 2 with clean water to allow the material to fully absorb water and stir;

[0064] Step four, install the mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com