Environment-friendly tin copper coating deplating solution and deplating method

An environment-friendly, stripping solution technology, applied in the field of chemical stripping of coatings, can solve the problems of increased stripping cost, difficult plating solution, etc., and achieves the effects of low cost, good stripping effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

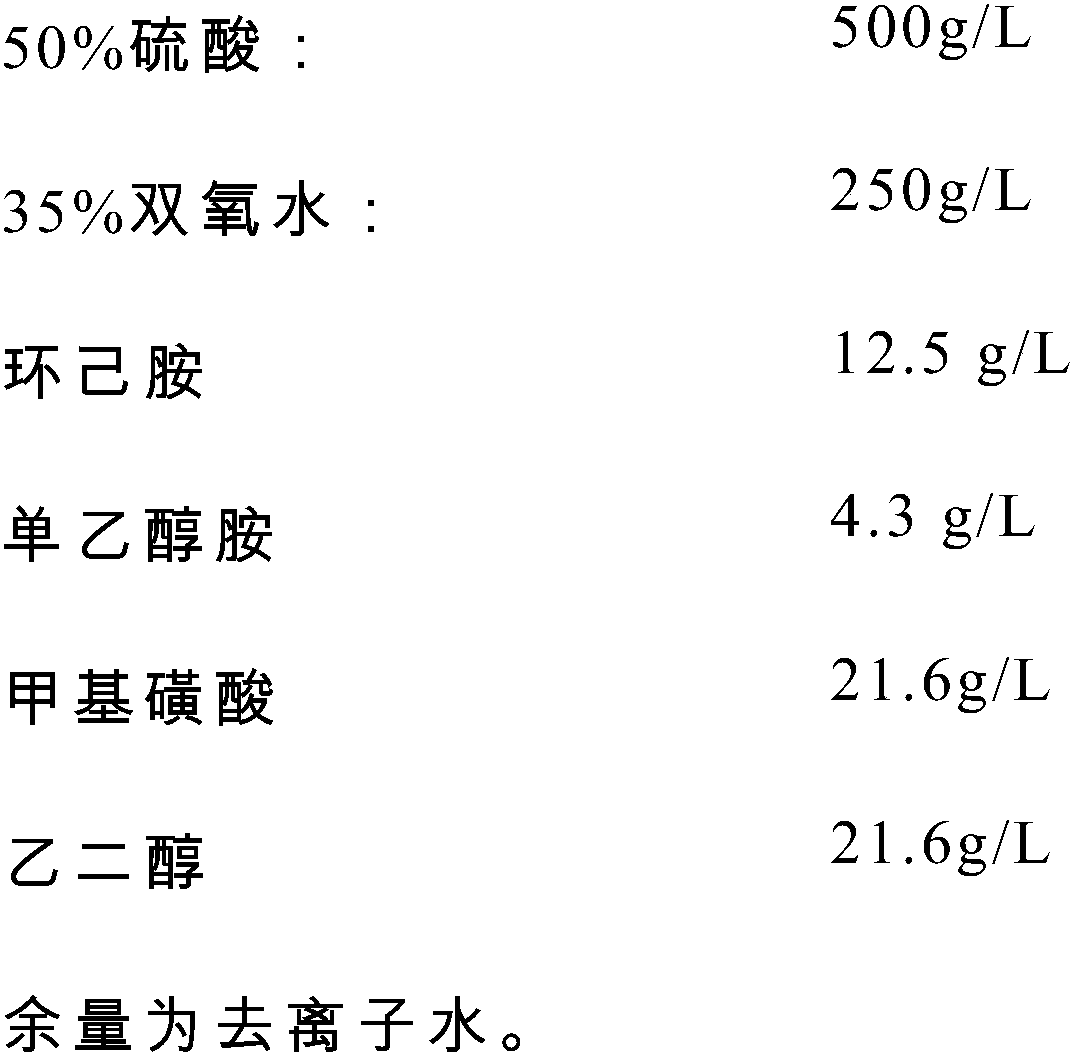

[0032] A kind of environment-friendly tin-copper coating stripping solution, every liter of this environment-friendly tin-copper coating stripping solution comprises:

[0033]

[0034] The deplating method is as follows: first put the plated piece coated with tin-copper coating into 5% dilute sulfuric acid and soak for 1-3 minutes; wash the dilute acid solution with water; then put the plated piece into the environment-friendly tin In the copper plating deplating solution, aim at the plating layer and carry out deplating by pumping, and the deplating time is 0.5-5 minutes; after the deplating is completed, it can be washed with water and dried.

Embodiment 2

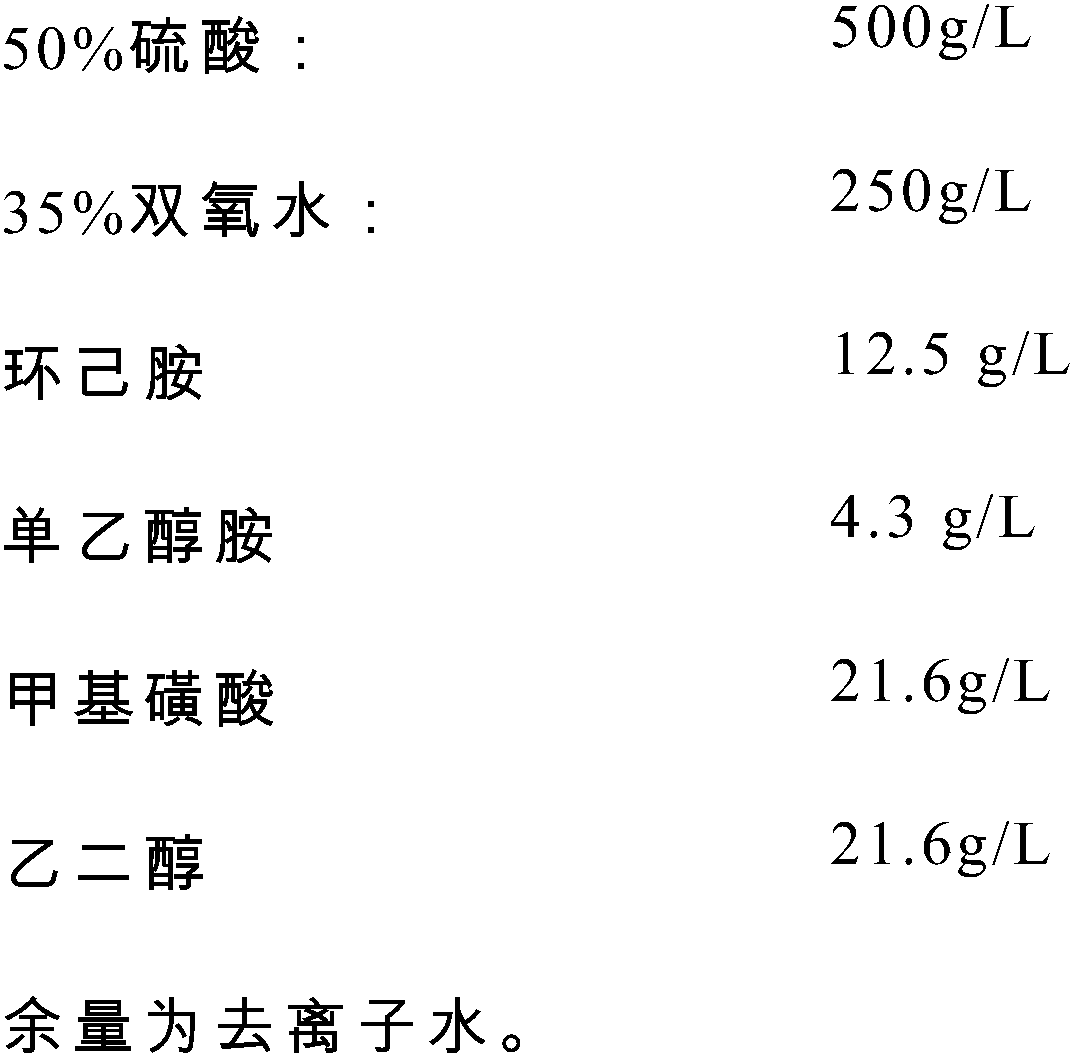

[0036] A kind of environment-friendly tin-copper coating stripping solution, every liter of this environment-friendly tin-copper coating stripping solution comprises:

[0037]

[0038]

[0039] The deplating method is as follows: first put the plated piece coated with tin-copper coating into 5% dilute sulfuric acid and soak for 1-3 minutes; wash the dilute acid solution with water; then put the plated piece into the environment-friendly tin In the copper plating deplating solution, aim at the plating layer and carry out deplating by pumping, and the deplating time is 0.5-5 minutes; after the deplating is completed, it can be washed with water and dried.

Embodiment 3

[0041] A kind of environment-friendly tin-copper coating deplating solution, every liter of this environment-friendly tin-copper coating deplating solution comprises:

[0042]

[0043]

[0044] The deplating method is as follows: first put the plated piece coated with tin-copper coating into 5% dilute sulfuric acid and soak for 1-3 minutes; wash the dilute acid solution with water; then put the plated piece into the environment-friendly tin In the copper plating deplating solution, aim at the plating layer and carry out deplating by pumping, and the deplating time is 0.5-5 minutes; after the deplating is completed, it can be washed with water and dried.

[0045] The stripping result of embodiment 1~3 is as follows:

[0046]

[0047] The present invention uses a hydrogen peroxide sulfuric acid system deplating solution, adds a deplating accelerator to the system, has stable properties and low cost, can effectively and quickly remove the tin-copper coating on the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com