Server high low temperature reliability automatic testing system and method

An automated test and server technology, applied in faulty hardware test methods, instruments, error detection/correction, etc., can solve problems such as increased reliability test time, incomplete information, and reduced work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0124] The high and low temperature reliability automatic test system of the server of the present invention is composed of a high temperature box, a pressurization module, and a temperature recording module.

[0125] The high temperature box can realize automatic heating and cooling. During the test, as shown in Table 1 below, set the running time of each temperature of the high temperature box to realize automatic heating and cooling of the high temperature box.

[0126] Table 1 The running time of each temperature in the high temperature box

[0127] temperature(℃)

time (h)

25

50%

2

40

50%

2

40

90%

2

40

90%

16

40

10%

2

40

10%

16

0

10%

2

0

10%

16

25

10%

2

25

10%

2

[0128] The pressurization module realizes the automatic pressurization of the pressurization software of the server to be tested through the testtool.sh script, a...

Embodiment 2

[0132] In the automatic test method for high and low temperature reliability of the server of the present invention, in the automatic test method, the temperature recording module cooperates with the high temperature box for automatic heating and cooling and the automatic pressurization module to realize the automation of the high and low temperature reliability test and the automatic recording of test data.

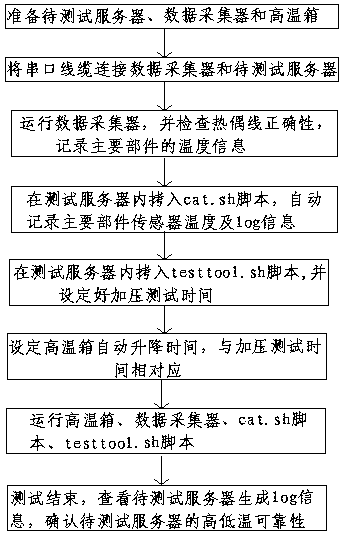

[0133] Such as figure 1 As shown, the automated testing method specifically includes the following steps:

[0134] S1: Prepare the server to be tested, the data collector and the high temperature box.

[0135] S2: Connect the serial port to RS32 cable to the 34970A data collector and the server to be tested to ensure a good connection.

[0136] S3: Open the 34970A software, run the data collector, check the correctness of the thermocouple wire, perform initial recording to ensure that all channels are recorded normally, and set the recording time of data collection to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com