Method of welding under electromagnetic action

A welding method and electromagnetic interaction technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of low construction efficiency, difficult welding, poor welding quality, etc., achieve convenient operation, improve welding quality and construction efficiency, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

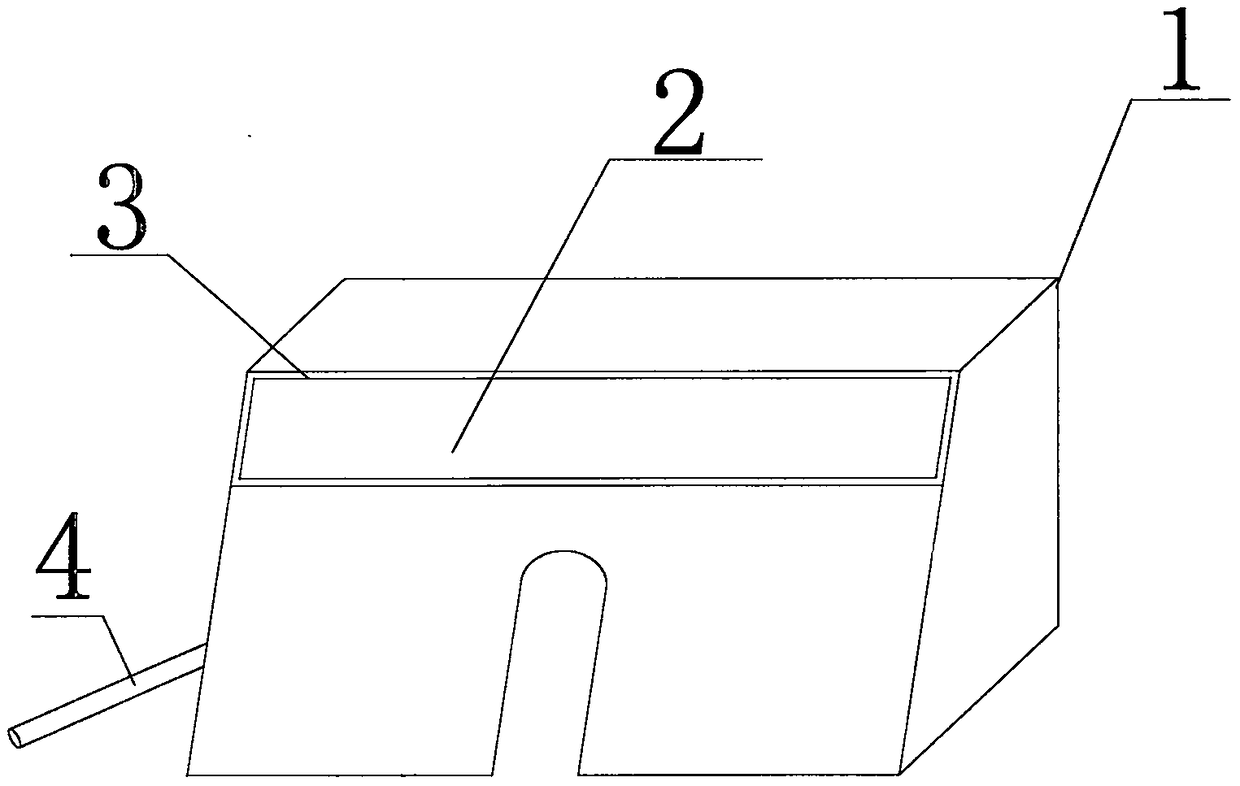

[0009] Embodiment one: see figure 1 , the present invention relates to a welding method under electromagnetic action. Firstly, a protective cover 1 for welding is made. The rear façade is rectangular, and a viewing port 3 is installed on the upper end of the slope directly in front of the protective cover 1; an electric welding protective lens 2 is installed on the viewing port 3; a U-shaped welding is opened at the lower end of the middle part of the slope in front of the protective cover 1 hole; a handle 4 is installed on a side elevation of the protective cover 1; then the protective cover 1 is placed on the position to be welded, and the welding torch is inserted into the protective cover 1 for welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com