Bamboo leftover mixed fiberboard and production method thereof

A technology of mixing fibers and scraps, applied in the direction of manufacturing tools, flat products, wood processing appliances, etc., can solve the problems of environmental protection and poor air permeability, and achieve the effect of solving formaldehyde release, high strength and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

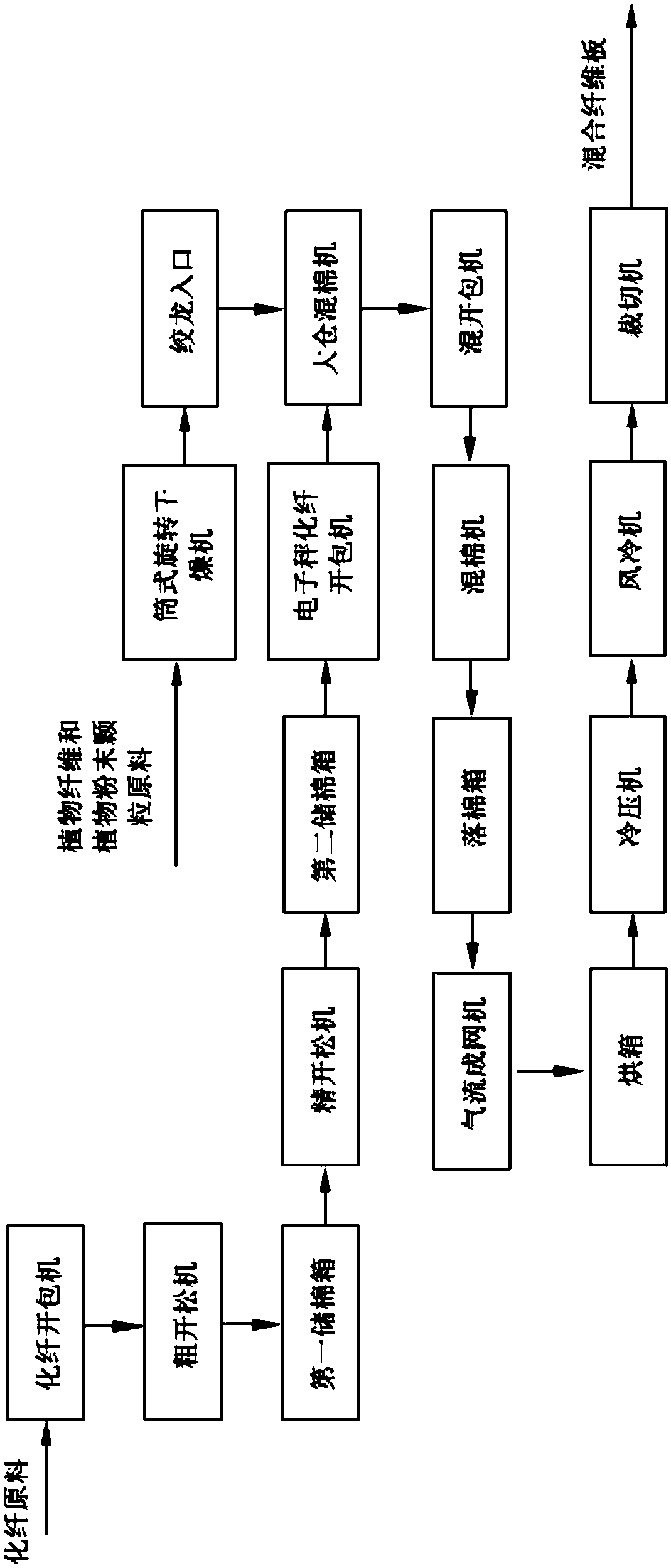

Method used

Image

Examples

Embodiment 1

[0047] The mixed fiberboard of bamboo and wood leftovers of the present embodiment comprises 10% low melting point chemical fiber, 20% plant fiber and 70% plant powder particles, wherein,

[0048] The plant fiber length is 5mm, the fineness is 5D, and the selected material is wood fiber;

[0049] The low-melting point chemical fiber is polypropylene fiber, the length is 10mm, and the fineness is 3D;

[0050] Plant powder particles are 100 mesh;

[0051] The temperature for heating and melting after air-laid is 160°C, and the temperature for wind cooling is 0°C;

[0052] The resulting mixed fiber mat had a thickness of 5 mm and a measured density of 0.46 g / cm 3 .

Embodiment 2

[0054] The bamboo and wood leftovers mixed fiberboard of the present embodiment comprises 20% low-melting point chemical fibers, 30% plant fibers and 50% plant powder particles, wherein,

[0055] The plant fiber length is 100mm, the fineness is 80D, and the selected material is bamboo fiber;

[0056] The low-melting point chemical fiber is polypropylene fiber, the length is 200mm, and the fineness is 10D;

[0057] Plant powder particles are 200 mesh;

[0058] The temperature for heating and melting after air-laid is 230°C, and the temperature for wind cooling is 20°C;

[0059] The resulting mixed fiber mat had a thickness of 10 mm and a measured density of 0.35 g / cm 3 .

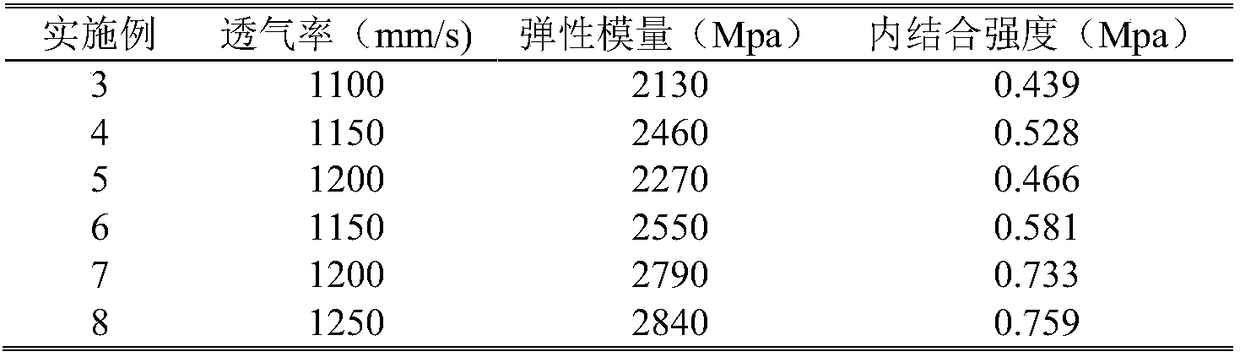

[0060] In order to conduct a series of strength tests and air permeability tests on the mixed fiberboards, the inventor manufactured a series of mixed fiberboards of equal thickness for performance analysis as follows.

Embodiment 3

[0062] The mixed fiberboard of bamboo and wood leftovers of the present embodiment comprises 10% low melting point chemical fiber, 20% plant fiber and 70% plant powder particles, wherein,

[0063] The length of the plant fiber is 20mm, the fineness is 30D, and it is a combination of wood fiber and bamboo fiber in a ratio of 4:6;

[0064] The low-melting point chemical fiber is polypropylene fiber, the length is 100mm, and the fineness is 5D;

[0065] Plant powder particles 100 mesh;

[0066] The temperature of heating and melting after air-laid is 170°C, and the temperature of wind cooling is 0°C;

[0067] The resulting mixed fiber mat had a thickness of 20 mm and a measured density of 0.47 g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com