Graphene water lubrication additive, as well as preparation method and application thereof

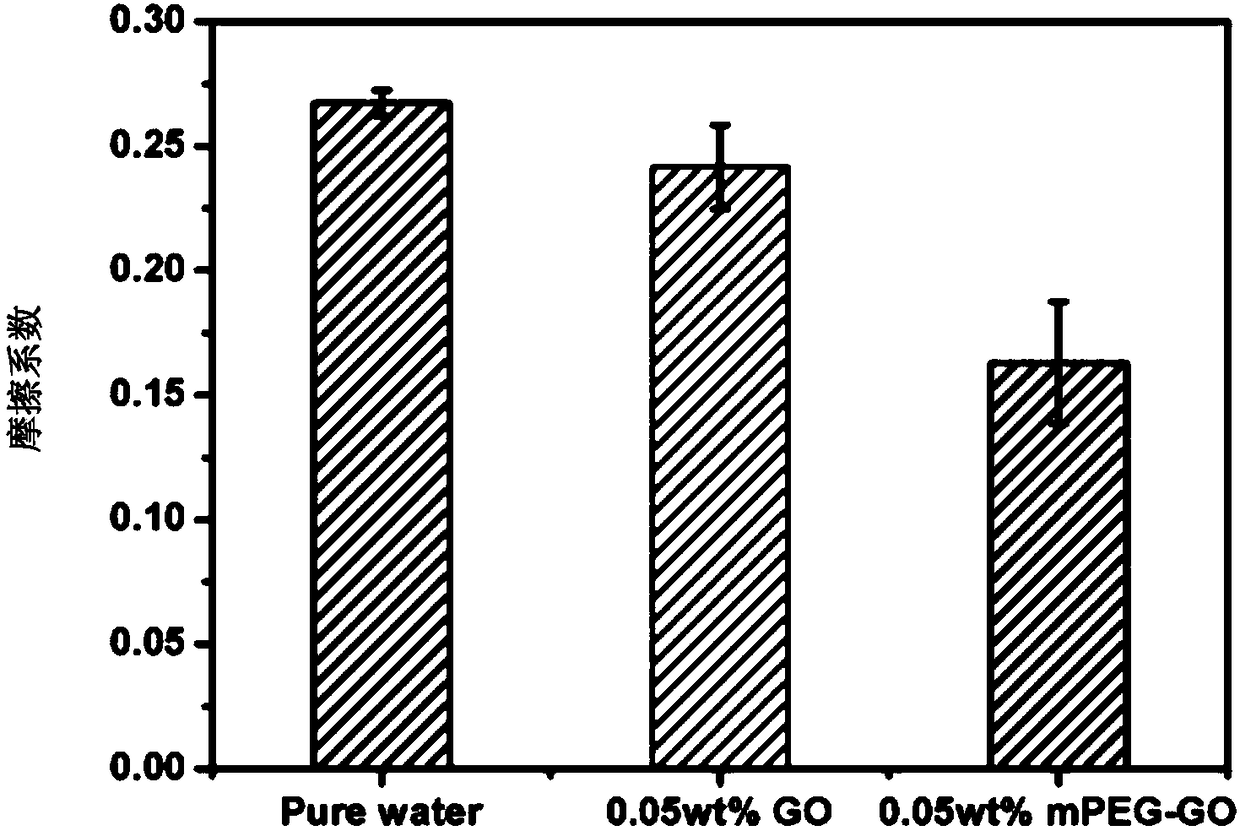

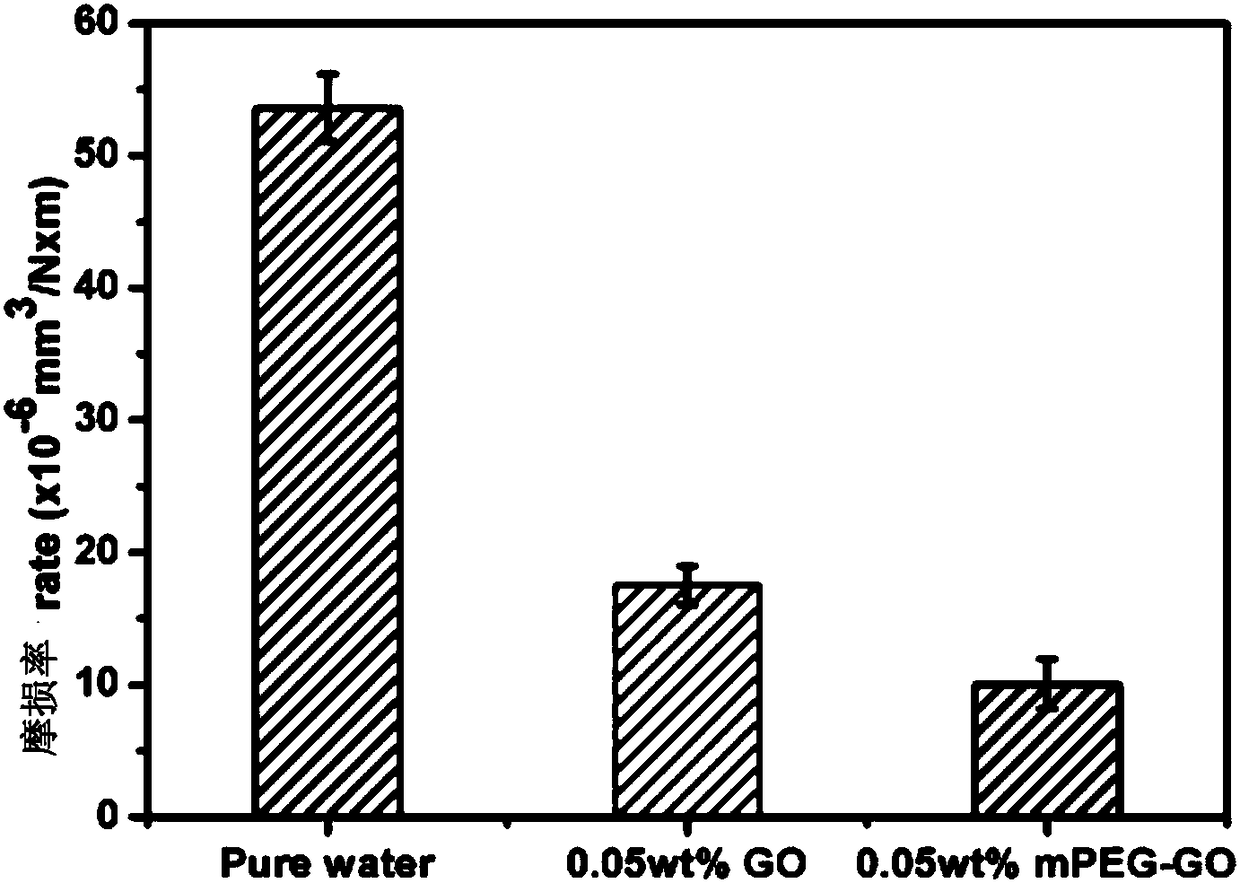

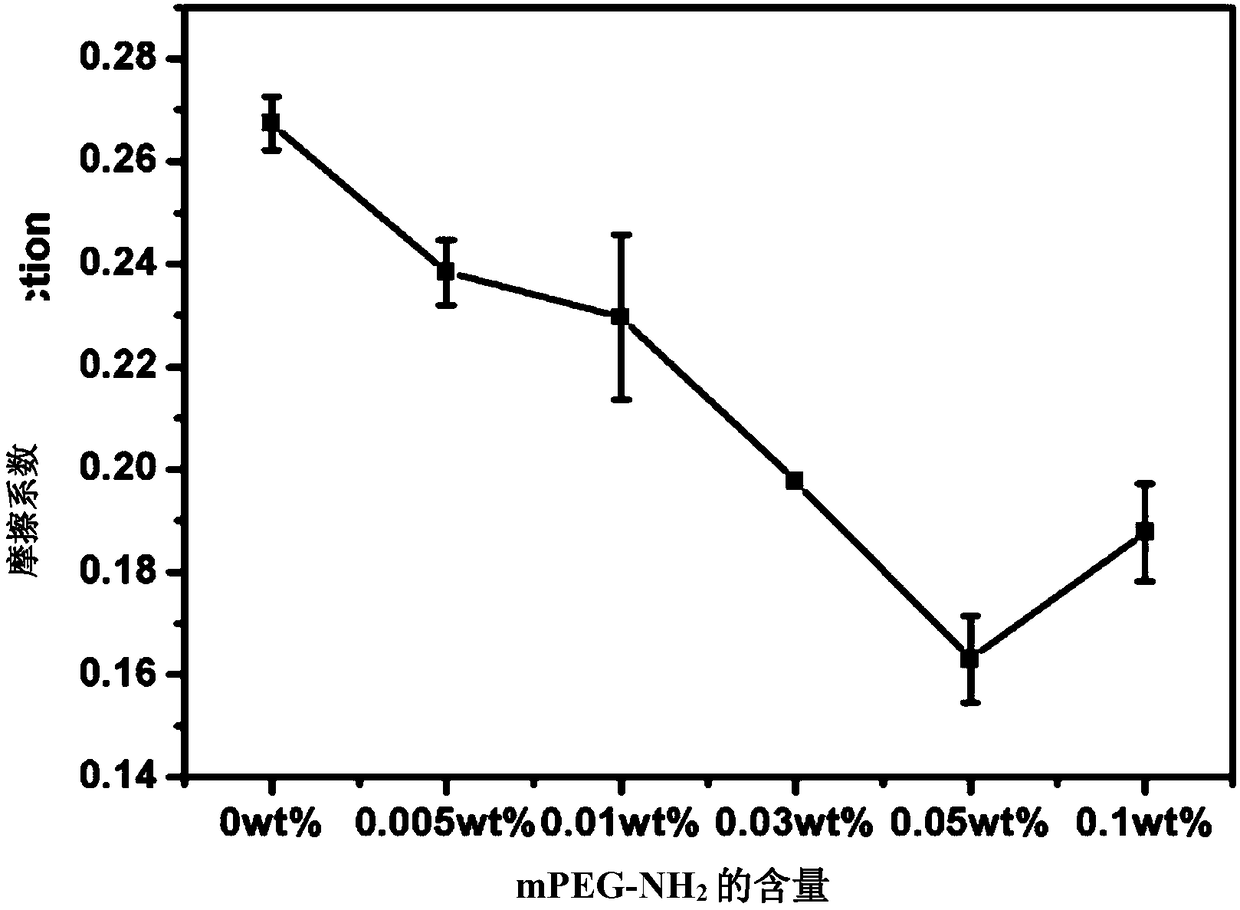

A water lubrication and additive technology, applied in the field of lubricant additives, can solve problems such as poor lubrication performance and weak adhesion, and achieve the effects of solving poor lubrication performance, reducing friction coefficient and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] An aspect of the embodiments of the present invention provides a PEG-NH 2 The preparation method of modified carboxylated graphene, it comprises:

[0035] reacting a first homogeneously mixed system comprising an amino-protecting group compound and ethanolamine to form amino-protected ethanolamine;

[0036] The second homogeneous mixing system comprising polyethylene glycol, bridging agent, and amino-protected ethanolamine is reacted to form polyethylene glycol derivatives (hereinafter referred to as PEG-NH for short) with amino groups. 2 ), as a yellow oil;

[0037] The polyethylene glycol derivatives with amino groups are used as modifiers and carboxylated graphene (G-COOH) to carry out amidation reaction to form polyethylene glycol derivatives (PEG-NH) with amino groups at one end. 2 ) modified carboxylated graphene (hereinafter referred to as PEG-G) to obtain graphene water lubricating additive.

[0038] In some embodiments, the preparation method includes: react...

Embodiment 1

[0070] Dissolve 200 mmol of di-tert-butyl dicarbonate in an appropriate amount of dioxane and slowly add it into 200 mmol of ethanolamine at 0° C. to react for 12 hours to obtain amino-protected ethanolamine. Add polyethylene glycol dropwise to toluene diisocyanate at 0°C to react for 2 hours, then add the amino-protected ethanolamine obtained above at 0°C to continue the reaction for 2 hours, the molar mass of polyethylene glycol, amino-protected ethanolamine and toluene diisocyanate The ratio is 1:1:1, and using trifluoroacetic acid to remove the amino protecting group can obtain polyethylene glycol derivatives with amino groups (PEG-NH 2 ), as a yellow oil.

[0071] 200mg carboxylated graphene (purchased from Hangzhou Carbon Nanomaterials Co., Ltd.) and an appropriate amount of PEG-NH 2 Disperse in 100ml deionized water (carboxyl and PEG-NH in carboxylated graphene 2 The molar ratio of the amino group is 1:1), add an appropriate amount of EDC to activate the carboxyl grou...

Embodiment 2

[0073] Dissolve 200 mmol of di-tert-butyl dicarbonate in an appropriate amount of dioxane and slowly add it into 200 mmol of ethanolamine at 5° C. to react for 16 hours to obtain amino-protected ethanolamine. Add polyethylene glycol dropwise to toluene diisocyanate at 25°C for 3 hours and then add the amino-protected ethanolamine obtained above at 25°C to continue the reaction for 3 hours, wherein the molar ratio of polyethylene glycol to amino-protected ethanolamine is 1 : 1, the molar ratio of polyethylene glycol to toluene diisocyanate is 1:1.2, and use trifluoroacetic acid to remove the amino protecting group to obtain polyethylene glycol derivatives with amino groups (PEG-NH 2 ), as a yellow oil.

[0074] 200mg carboxylated graphene (purchased from Hangzhou Carbon Nanomaterials Co., Ltd.) and an appropriate amount of PEG-NH 2 Disperse in 100ml deionized water (carboxyl and PEG-NH in carboxylated graphene 2 The molar ratio of the amino group is 1:1), add an appropriate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com