AGV device-based logistics multi-task control system and control method

A control method and technology of a control system, applied in the directions of logistics, conveyor control devices, conveyor objects, etc., can solve problems such as not being fully satisfied, and the use of hardware buffer stations is different, so as to avoid disconnection and realize material flow. The effect of the process of connecting with information flow and strengthening security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with specific embodiments.

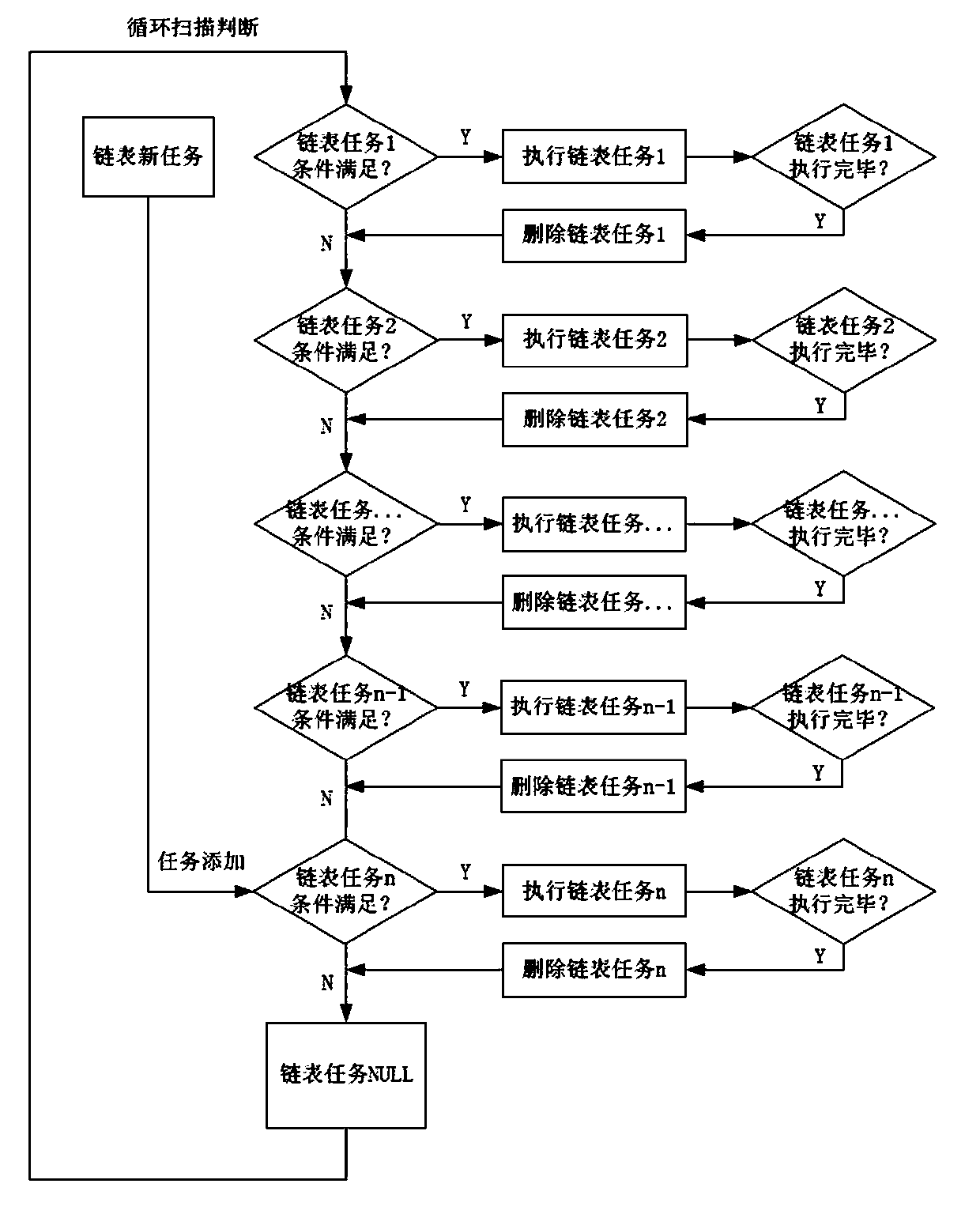

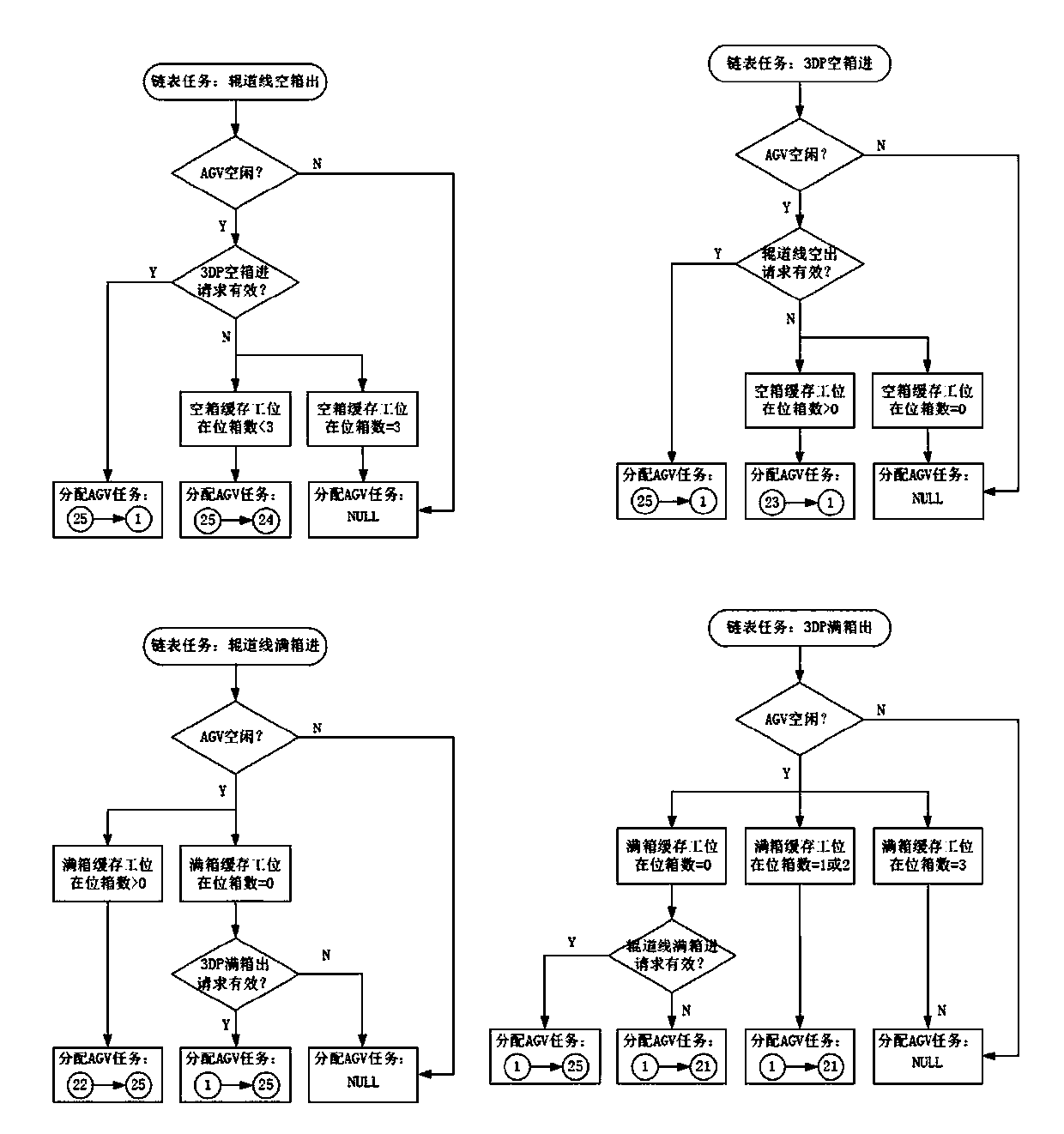

[0050] The present invention consists of three parts: equipment and hardware deployment, data communication and processing, multi-task scheduling and single-task execution.

[0051] Equipment and hardware deployment.

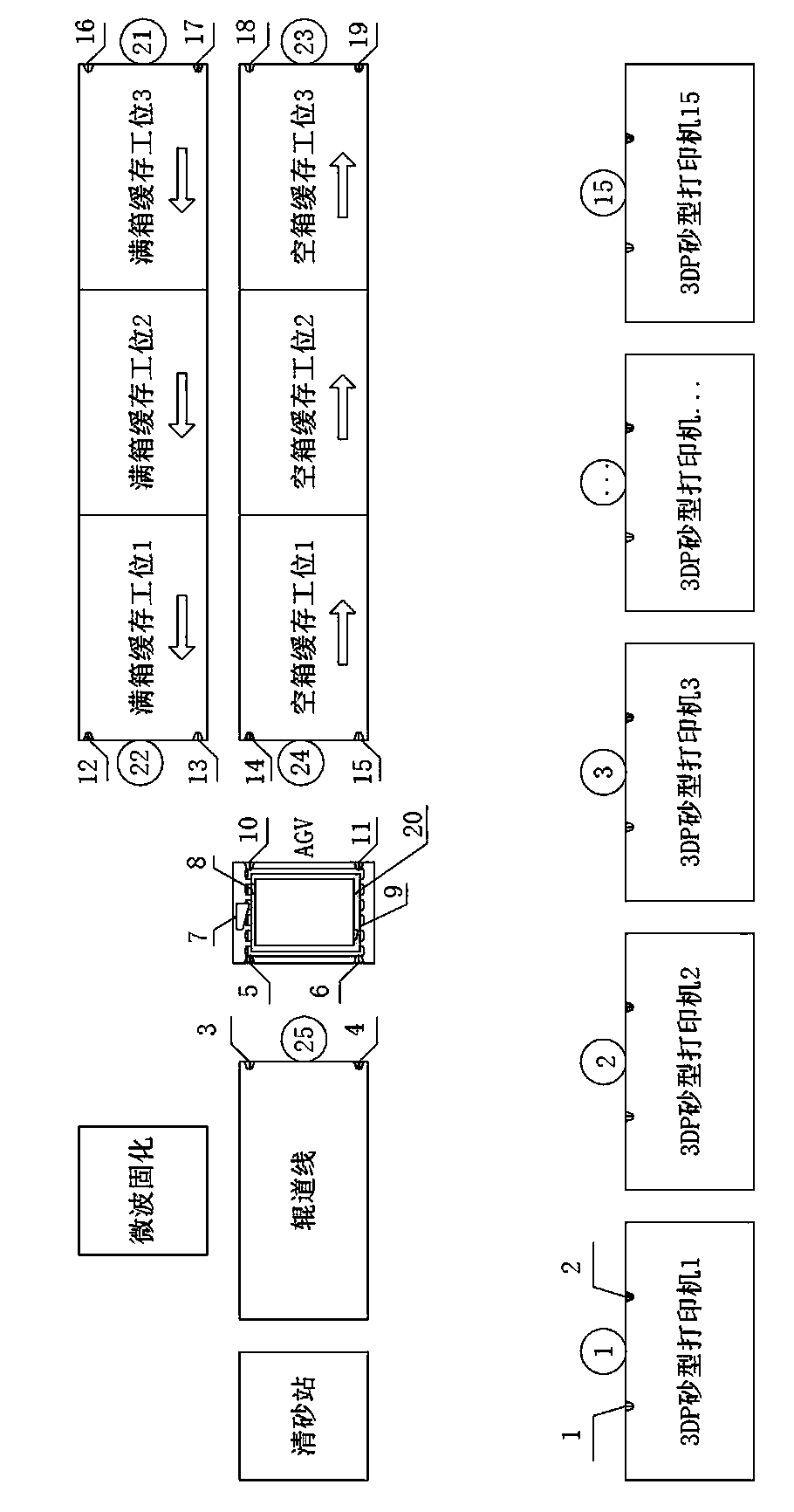

[0052] Device deployment

[0053]

[0054] hardware deployment

[0055] Take the 3DP sand printer 1 as an example; the same type of infrared receiver and infrared emitter are deployed in pairs at the front end and rear end of the AGV, roller line, 3DP sand printer and both ends of the buffer station to make up for the lack of positioning of the AGV itself; That is, when the AGV is docked with the 3DP sand printer, the buffer station, and the roller table line, the AGV's own positioning conditions and the simultaneous action of the two sets of infrared receiver signals must be met at the same time, so that the roller tables of the respective e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com