Motor stator and manufacturing method thereof, stator pieces of motor stator, sewing machine energy saving motor of motor stator and sewing machine of motor stator

A motor stator and stator sheet technology, which is applied to sewing machine components, sewing machine control devices, and manufacturing stator/rotor bodies, etc., can solve problems such as large waste, motor failure, and large area of a single silicon steel sheet, and achieve easy manufacturing, Easy-to-make, easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

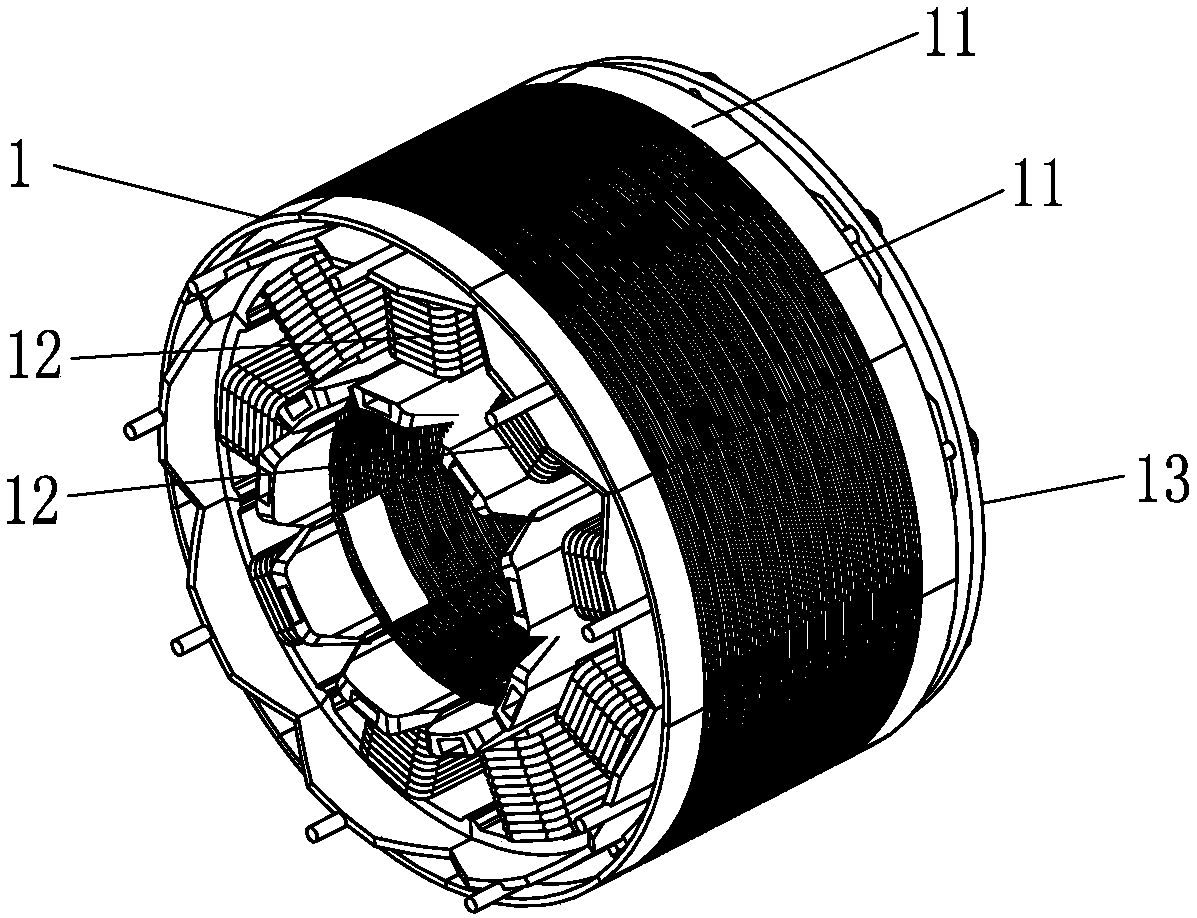

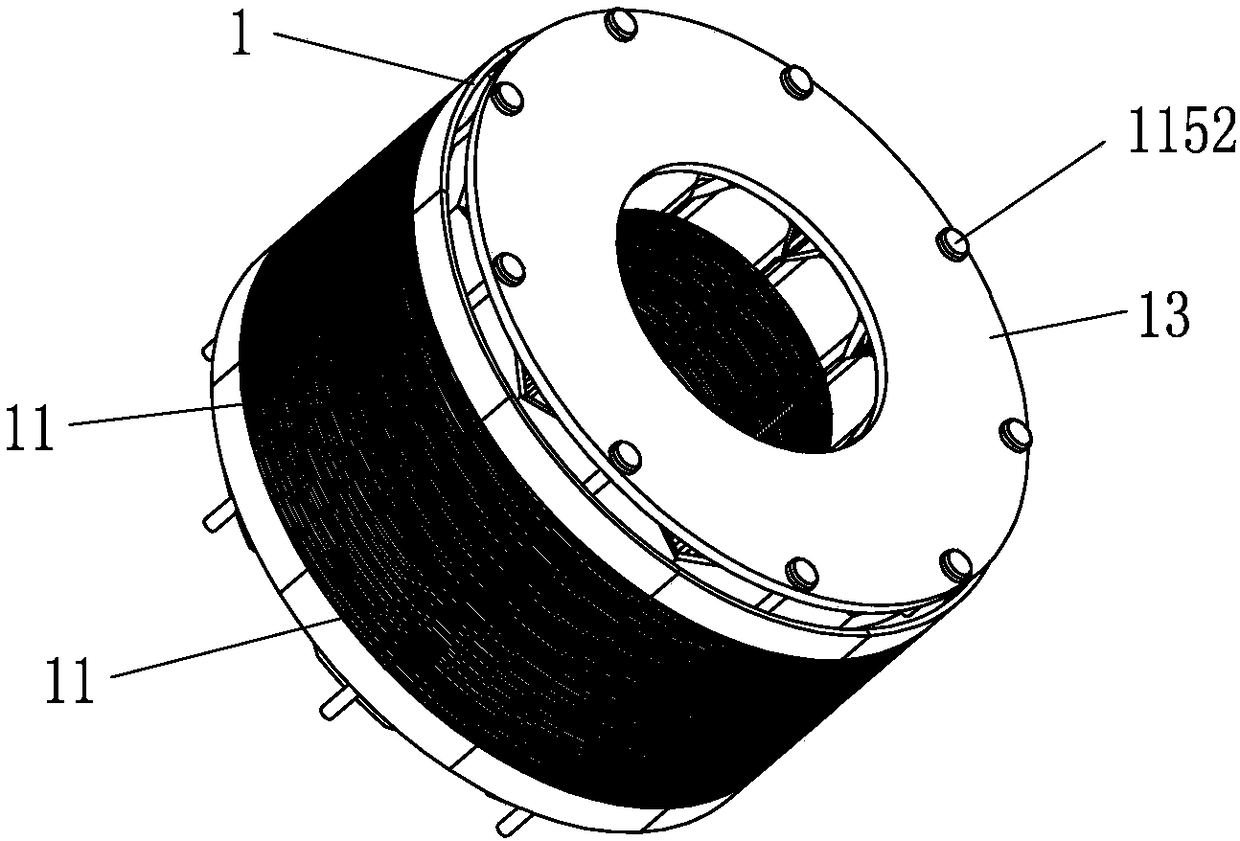

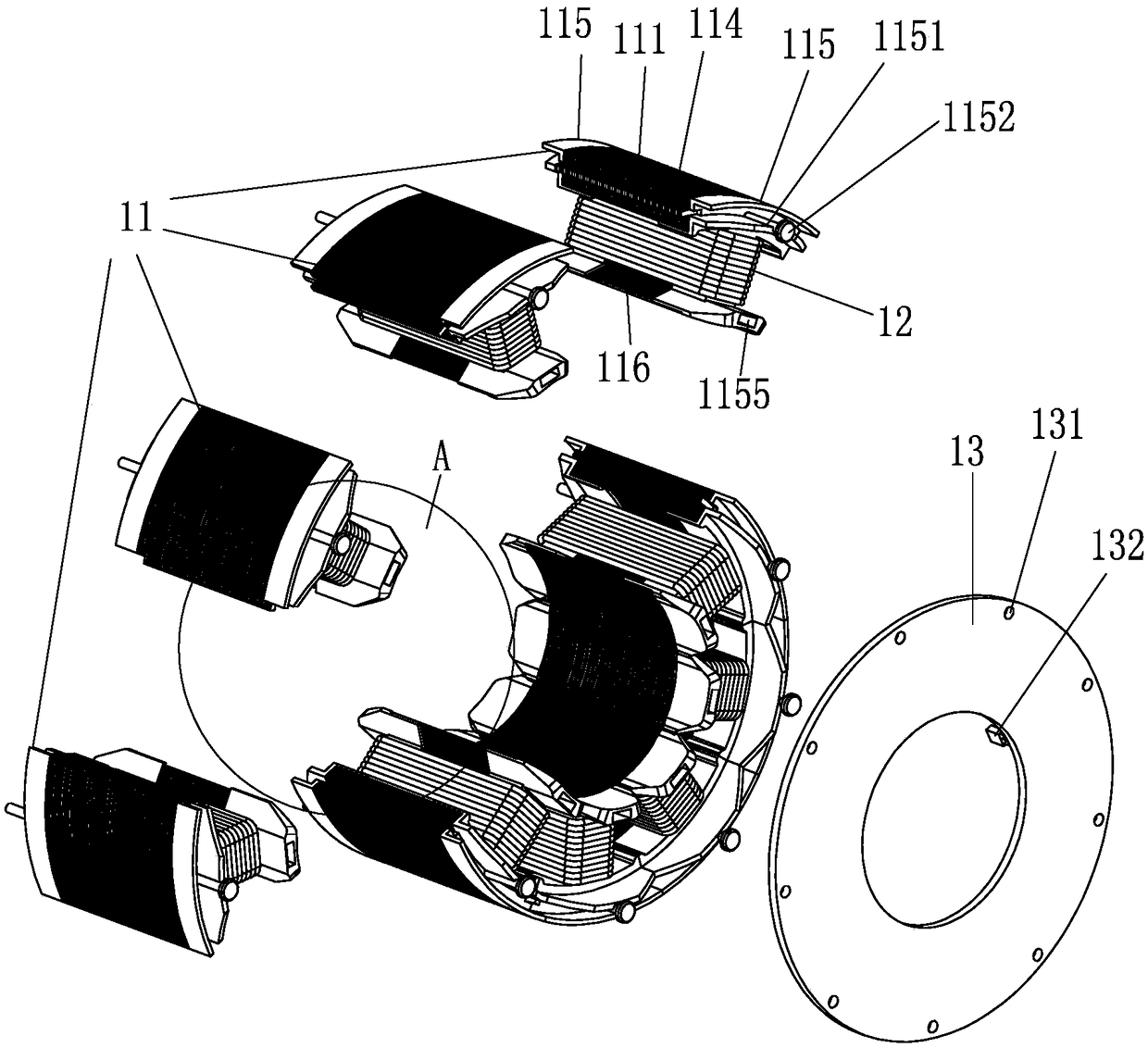

[0048] Attached below Figures 1 to 13 The present invention is described further:

[0049] A motor stator, the stator 1 includes a plurality of stator posts 11 and stator windings 12 wound on the stator posts 11, the stator post 11 includes an outer edge plate 111 and a Winding the winding post 112 of the stator winding, the outer edge plate 111 and the winding post 112 surround an open slot 113 for the stator winding to pass through, and the stator post 11 includes a plurality of stator sheets 110 stacked The stator column main body 114 and the insulators 115 provided on both ends of the stator column main body 114, the stator piece 110 includes an outer edge portion 1101 and a winding portion 1102 connected to the outer edge portion 1101, the outer edge portion 1101 The outer edge plate 111 and the winding column 112 are correspondingly formed after the stator piece 110 is superimposed with the winding part 1102. The outer edge plates 111 of all the stator columns 11 are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com