Steel sheet tin filling grounding process

A steel sheet and tin-filling technology, which is applied to printed circuit grounding devices, circuit devices, printed circuit components, etc., can solve problems such as poor contact of flexible circuit boards, weak bonding of conductive adhesives, and poor performance of conductive adhesives. Static electricity and overall performance improvement, eliminating the need for conductive adhesive bonding process, and reducing the effect of grounding impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable those skilled in the art to better understand the technical solution of the present invention, the product of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

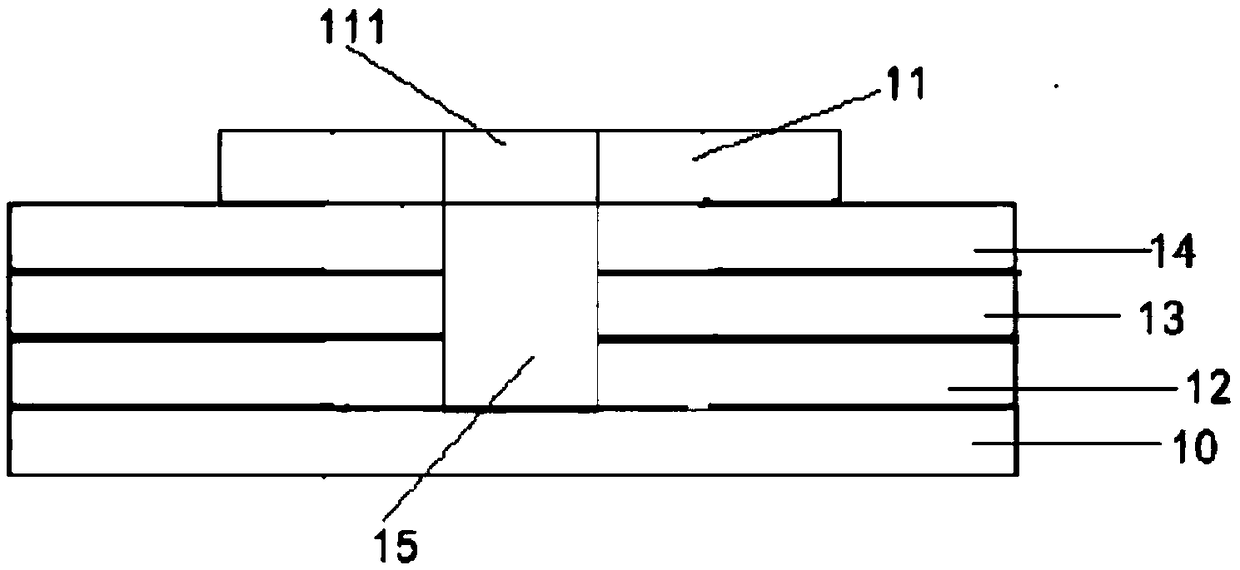

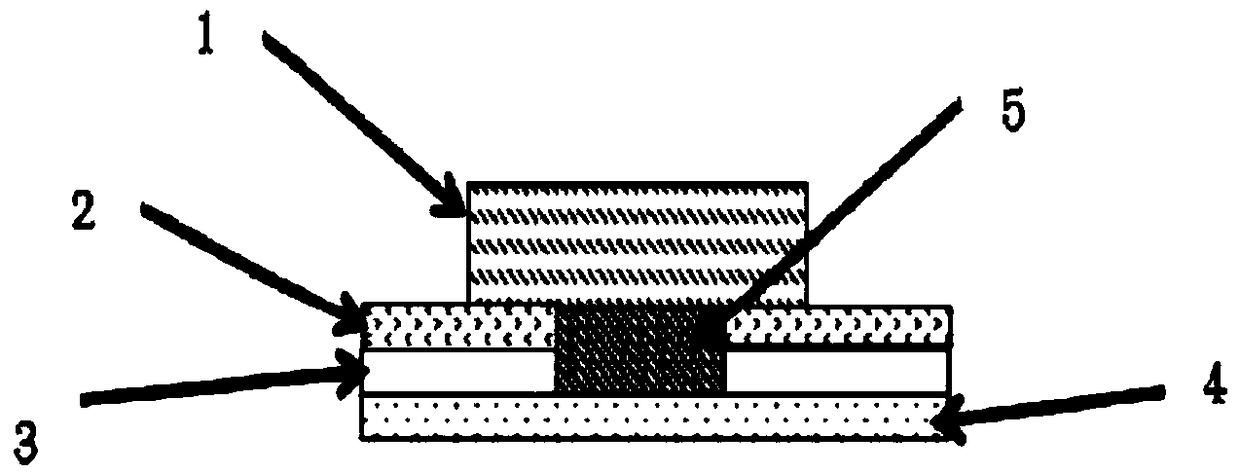

[0016] As shown in the figure, the present invention discloses a steel sheet filling tin grounding process, including a steel sheet 4, a flexible circuit board 2 and an electronic component 1 arranged on the circuit board, and the circuit board is provided with an ESD-GND , ESD is Electro-Static discharge;

[0017] The electronic components are located on the front of the circuit board, and the steel sheet is located on the back of the circuit board; a hole is made at the position where the electronic components are installed on the circuit board, and one end of the through hole is connected to the electronic component. The other end communicates with the steel sheet; after pouring solder paste into the through hole,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com