Flow restrictor for an injector

A flow restrictor and injector technology, which is applied in fuel injection devices, special fuel injection devices, fuel injection devices with oil reservoirs, etc., can solve the problems of easy wear and tear, improve wear behavior, avoid functional interference, The effect of contact pressure peak reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

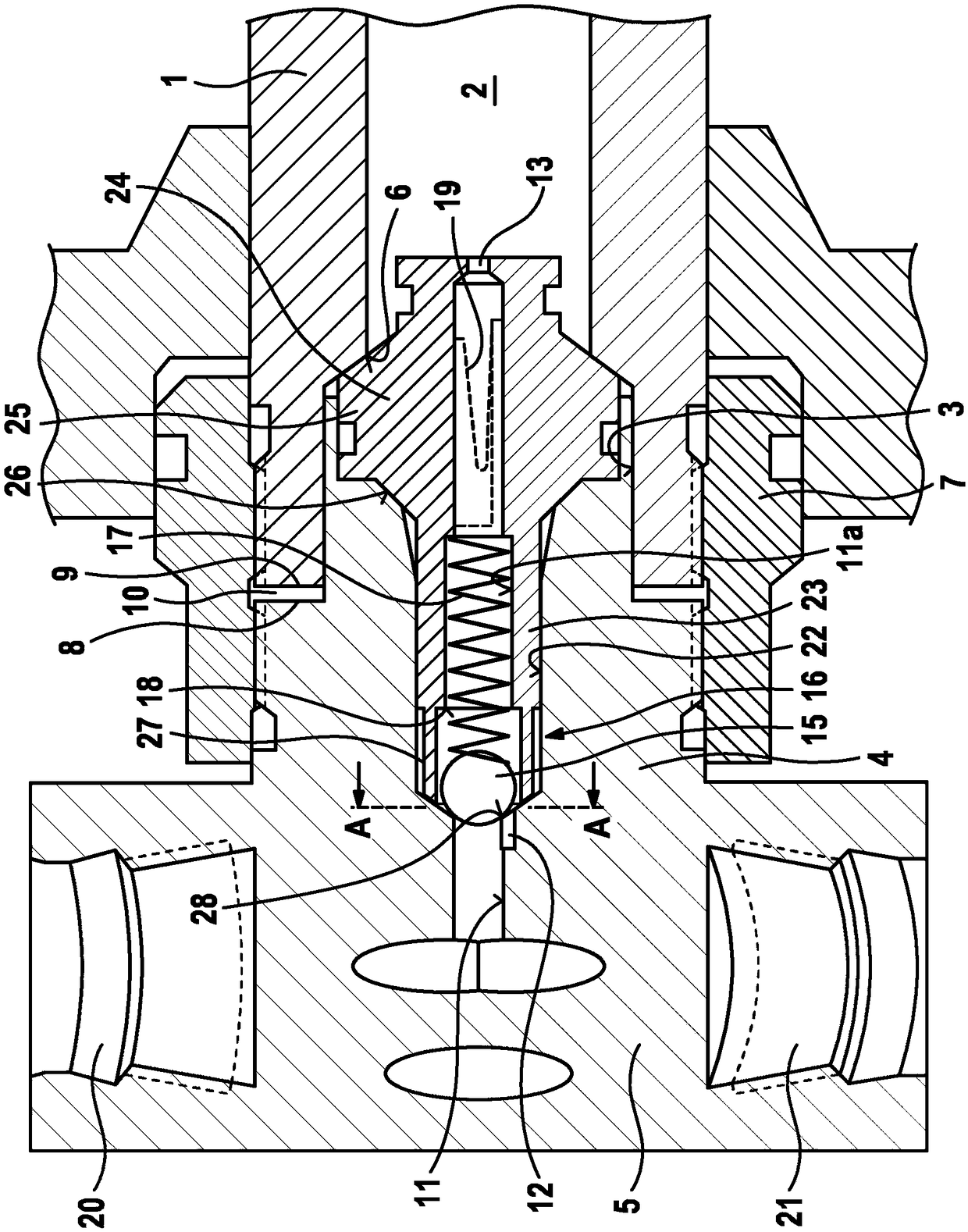

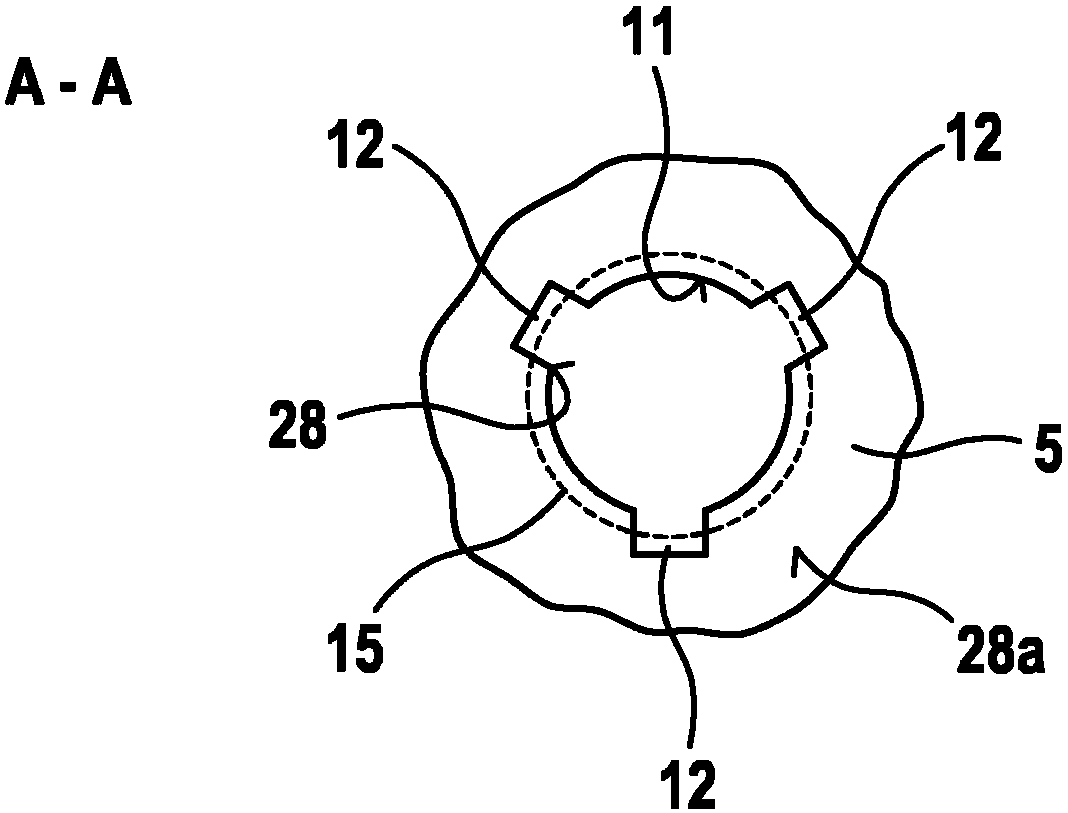

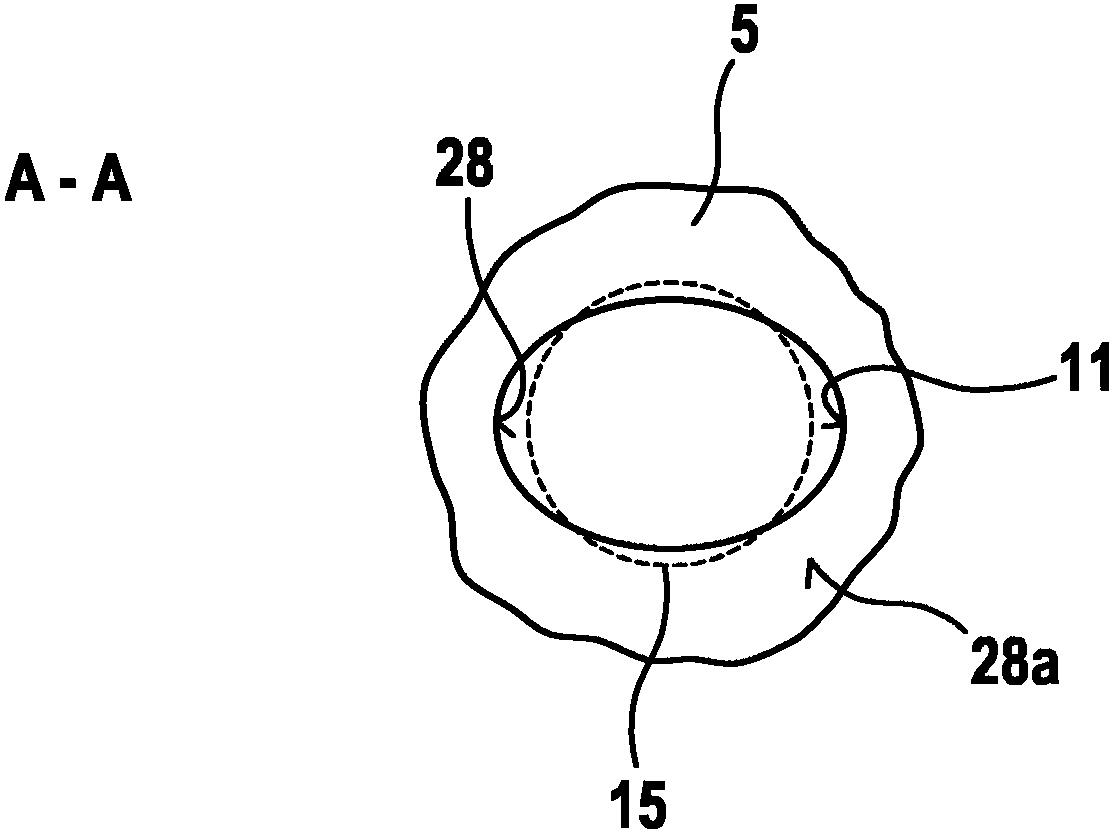

[0022] figure 1 shows the end section of the injector body 1 of the injector in which the high-pressure accumulator 2 is integrated. The injector body 1 can also be referred to as a holding body. The injector has a flow restrictor 16, wherein the flow restrictor 16 comprises a valve housing 24, an axial bore 11a formed in the valve housing 24, a ball 15 serving as a closing body and arranged in the axial bore 11a, a construction Valve seat 18 and bearing seat 28 on valve housing 24 .

[0023] The injector body or holding body 1 has an opening 3 leading to the high-pressure accumulator 2 , into which opening the screw-type section 4 of the closing screw 5 is introduced. The closing screw 5 is screwed to the injector body 1 by means of a clamping nut 7 , wherein the internal thread of the clamping nut 7 cooperates with the axially adjacent external threads of the injector body 1 and of the closing screw 5 .

[0024] A high-pressure connection 20 and a further high-pressure co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com