Electrical machine comprising radial cooling slots, and wind power generation facility

A technology of radial cooling and cooling grooves, applied in wind power generation, wind turbines, cooling/ventilation devices, etc., to achieve the best utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

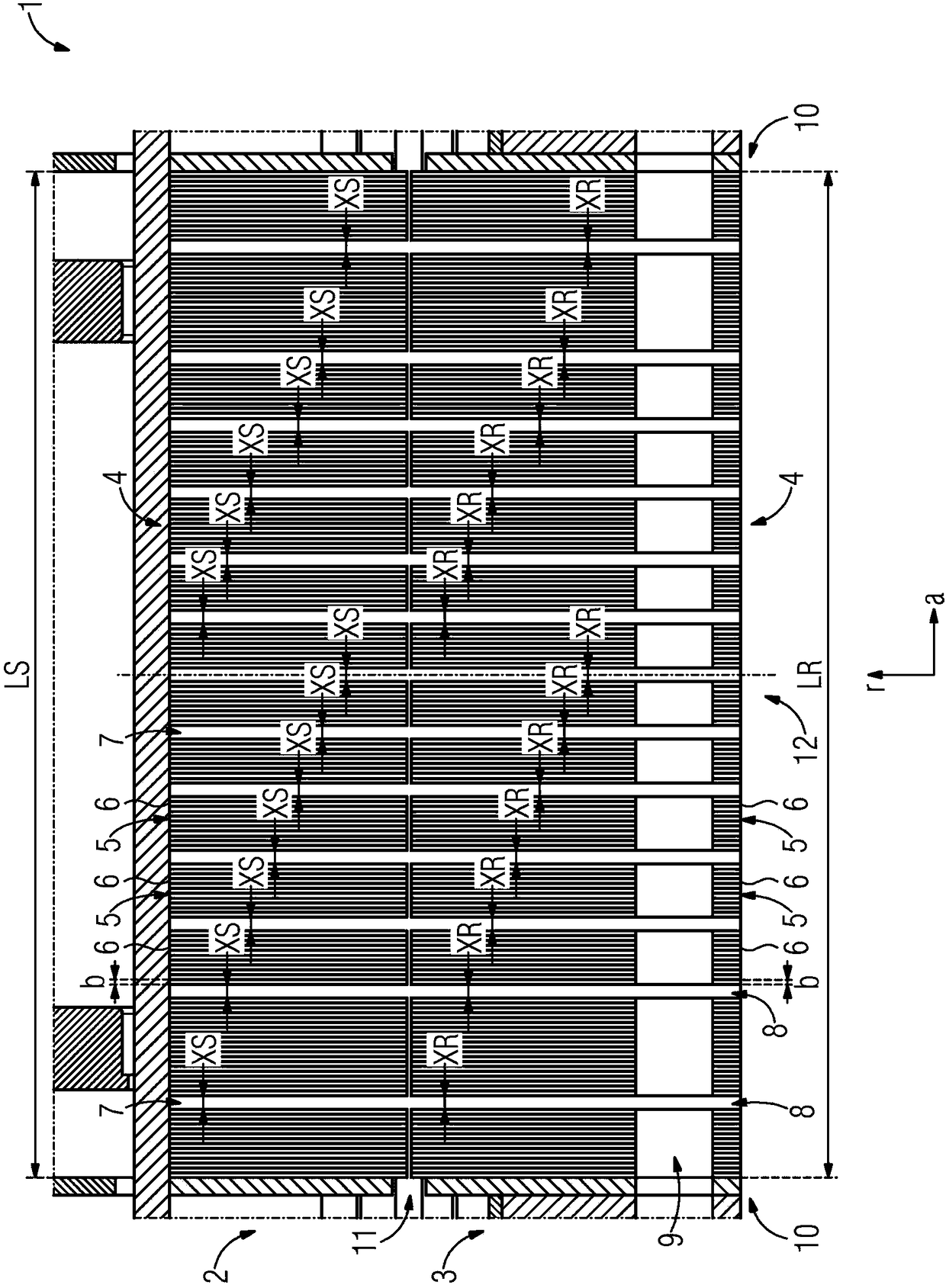

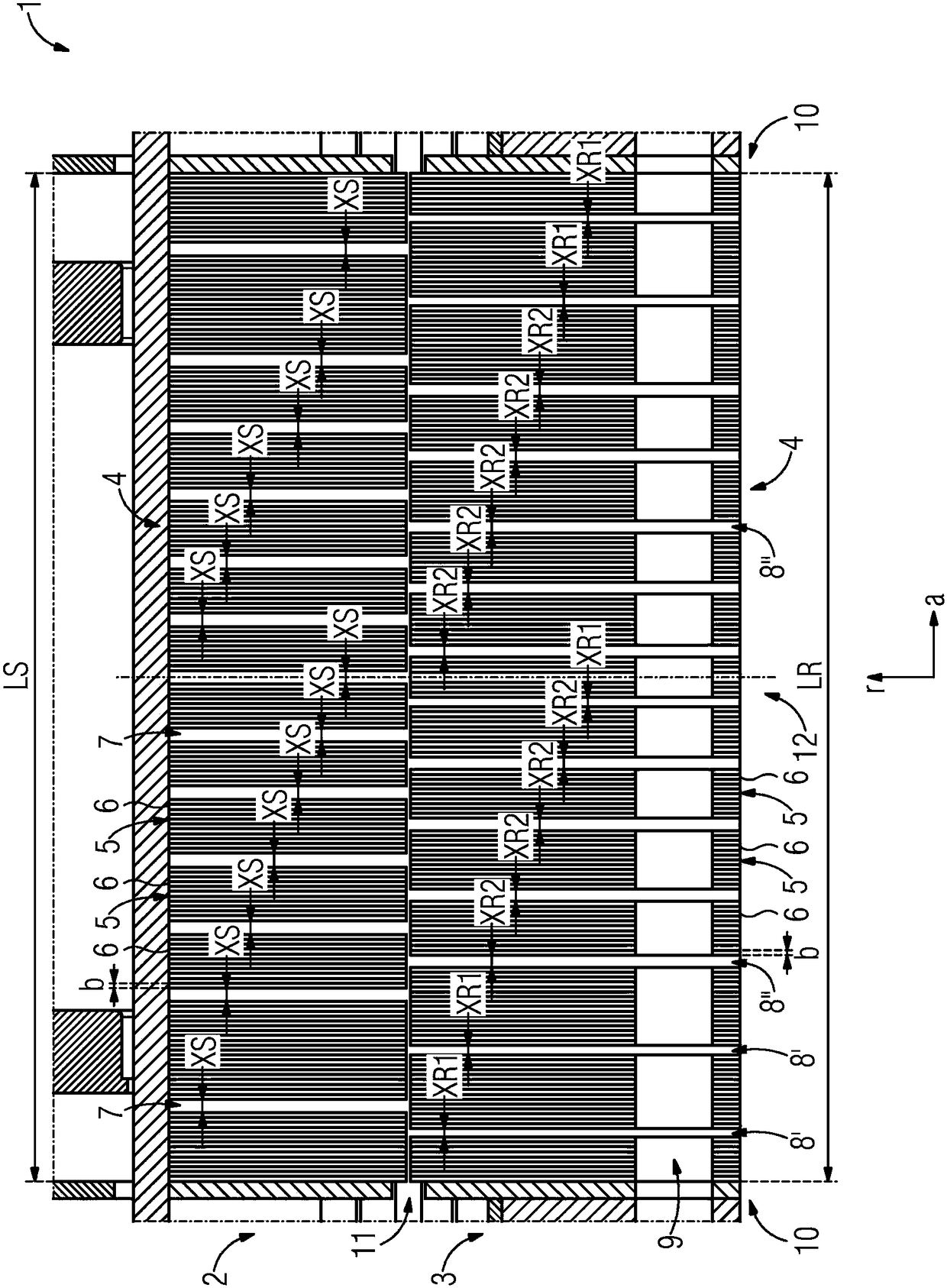

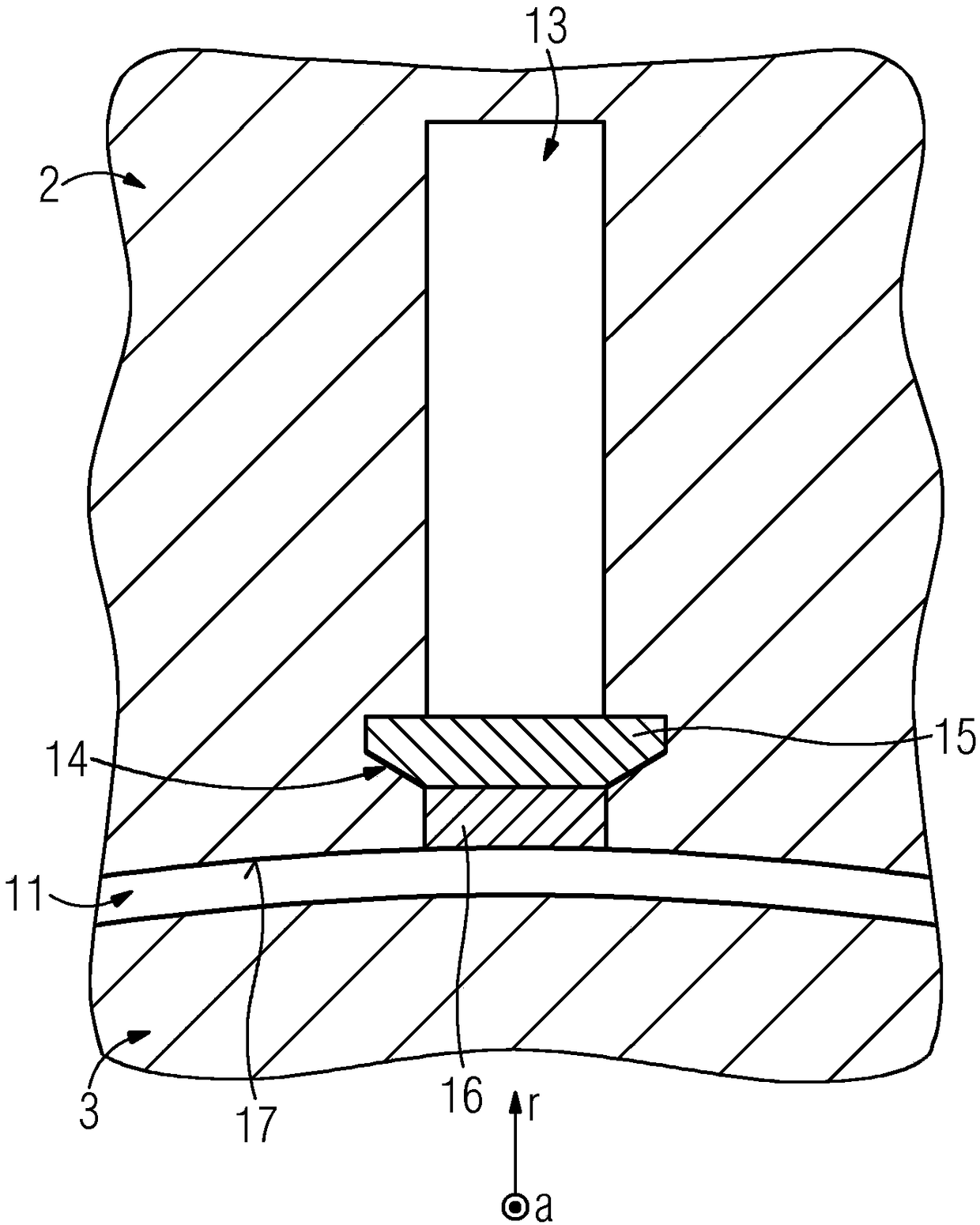

[0031] In the figures, identical and functionally identical elements have the same reference signs.

[0032] figure 1 An electric machine 1 according to the prior art is shown in a sectional side view. The electric machine 1 comprises a first active part 2 in the form of a stator. Furthermore, the electric machine 1 comprises a second active part 3 in the form of a rotor. The second active part 3 can move or rotate relative to the first active part 2 . The first active part 2 has an overall length LS in the axial direction a of the electric machine 1 and the second active part 3 has an overall length LR in the axial direction a. Currently, the total lengths LS and LR of the active parts 2, 3 are the same.

[0033] Both the first active part 2 and the second active part 3 comprise a lamination stack 4 having a plurality of individual laminations 6 . The individual laminations 6 are combined into corresponding sub-lamination groups 5 . The individual laminations 6 have an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com