Rigidity-controllable positive stress electromagnetic vibration platform and control method

An electromagnetic vibration and vibration platform technology is applied in the direction of using electromagnetic means, using vibrating fluid, and using electrical devices. It can solve the problems of large power consumption, poor anti-overload ability, coil heating, etc., and achieve fast response speed and frequency band. The effect of large range and low heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

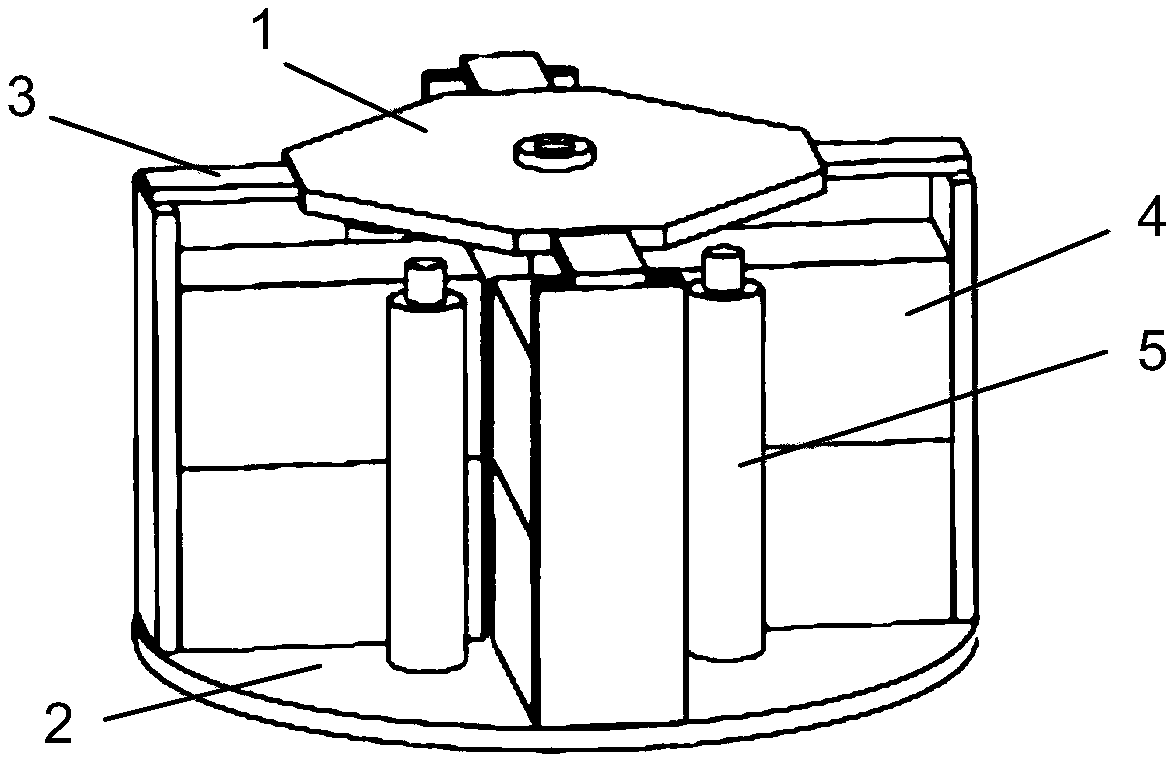

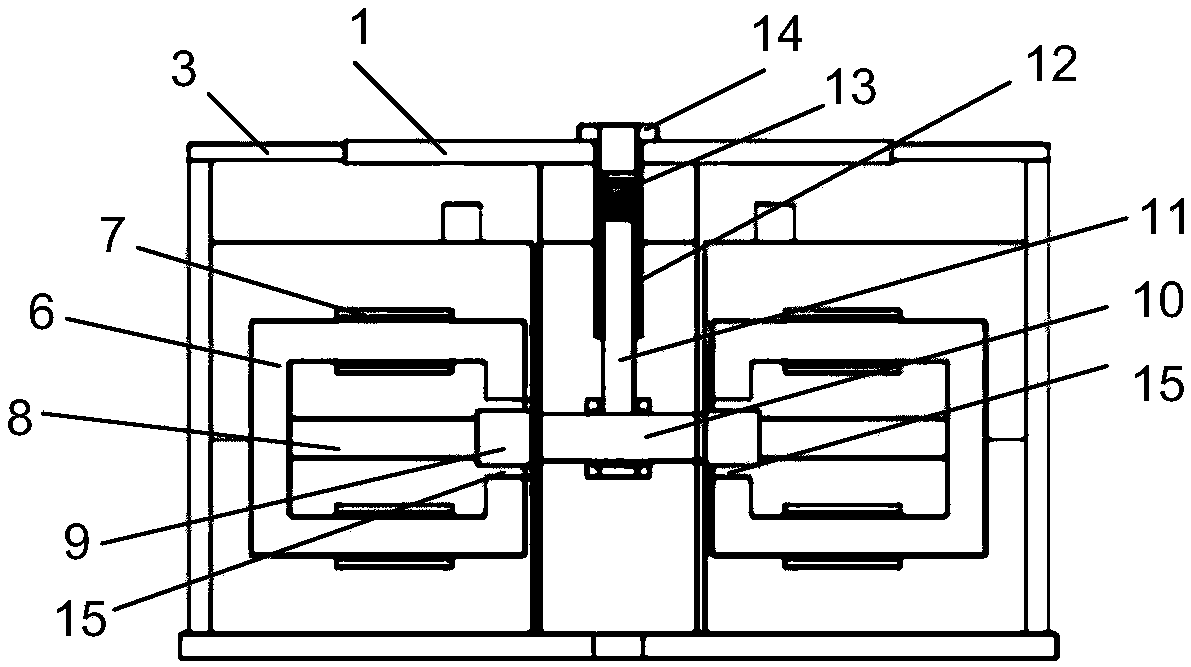

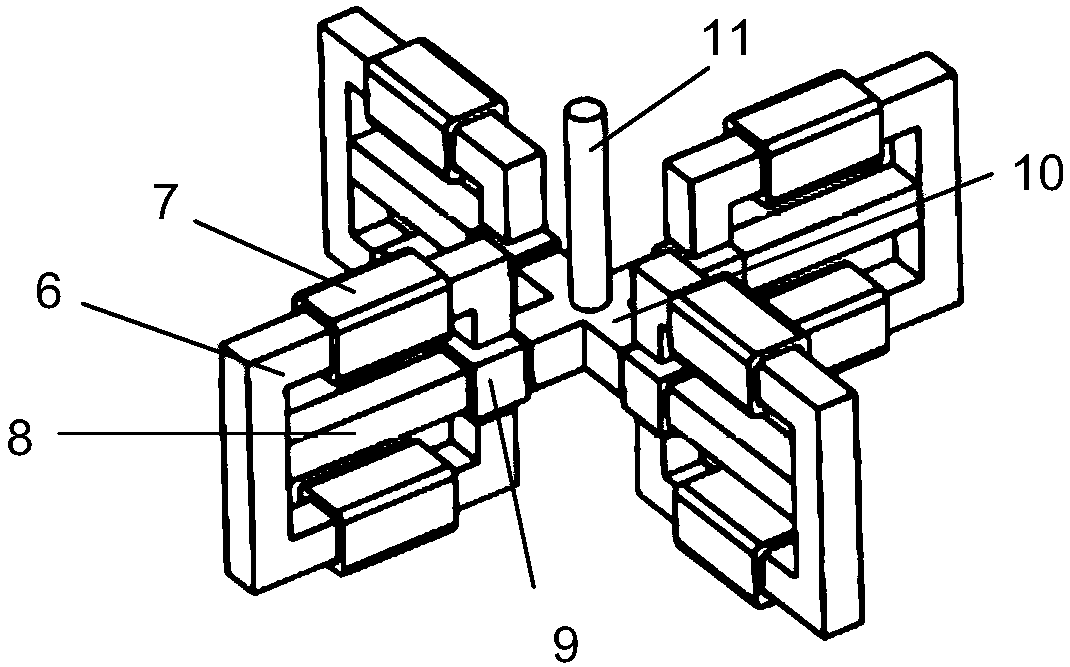

[0020] Such as figure 1 As shown, a normal stress electromagnetic vibration platform with controllable stiffness of the present invention includes a vibration platform 1 and a base 2. The vibration platform 1 is connected to the base 2 through a cantilever beam supporting structure 3. The four normal-stress electromagnetic actuators 4 are installed on the base 2 by bolts, and are arranged symmetrically around the cross-shaped mass 10, and are distributed in pairs at a diagonal angle. An actuating rod 11 is installed in the center of the cross-shaped mass 10, the actuating rod 11 is connected to the vibrating platform 1 through a spring 13, the upper end of the spring 13 is connected to the pre-tensioning device 14 that is threadedly connected to the vibrating platform 1, and the outside of the actuating rod 11 A guide sleeve 12 fixed at the lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com