Electric wheel driving system integrating steering, roll preventing and driving and control method

A drive system, integrated wheel technology, applied in steering, anti-tilt and drive integrated wheel-side electric drive system and control field, can solve the problems of three-system space and motion interference, complex structure, large space occupation, etc., to save Available space and cost, simplified system structure, good system integration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

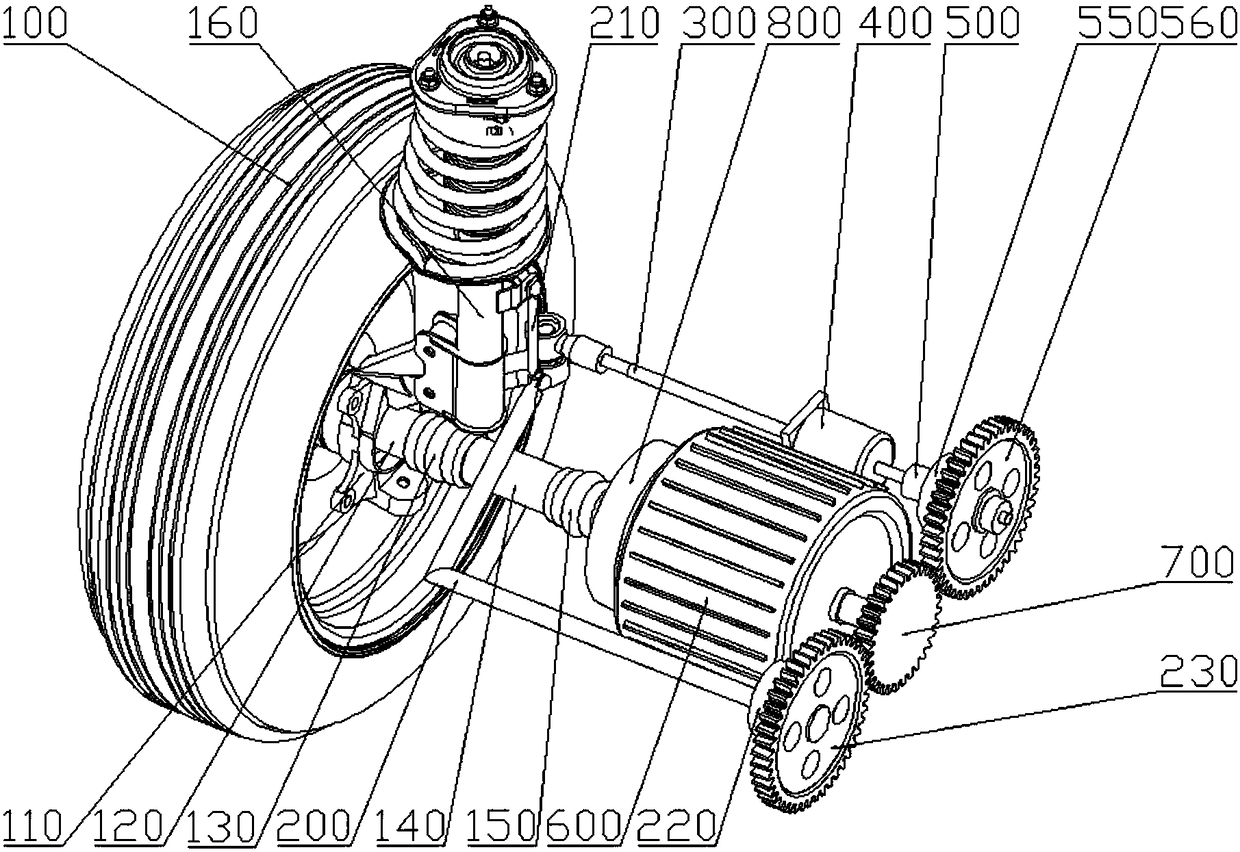

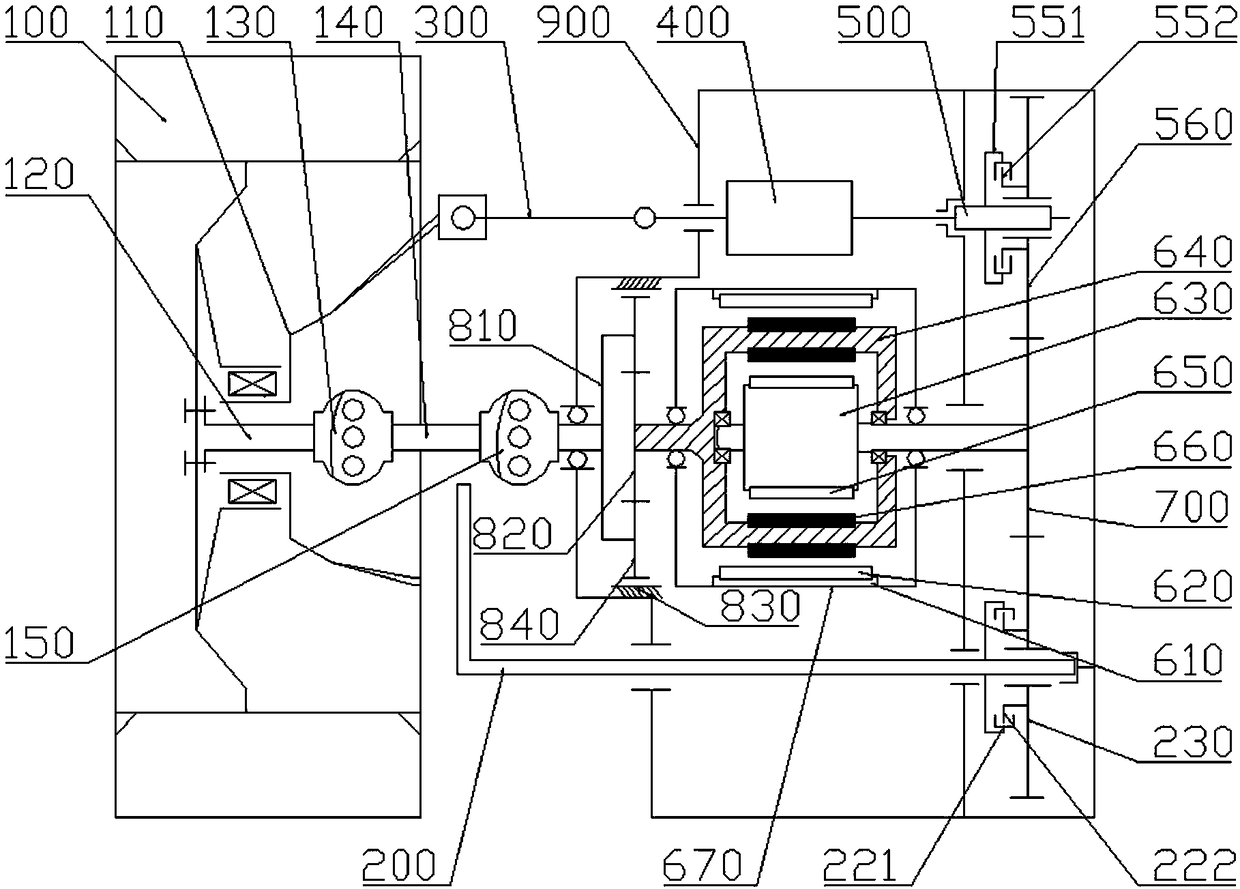

[0047] Such as Figure 1-2As shown, the present invention provides a steering, anti-roll and drive integrated wheel-side electric drive system, which includes an L-shaped anti-roll bar 200, an anti-roll connecting rod 210, a double-rotor motor 600, a linear motor 400, and a planetary gear reduction Device 800, ball screw mechanism 500, driving gear 700, steering gear 560, anti-tilt gear 230, first clutch 220, second clutch 550, steering knuckle 110, inner universal joint 150, outer universal joint 130, inner half Shaft 140 , outer half shaft 120 , tie rod 300 , shock absorber 160 and wheel drive housing 900 .

[0048] Such as figure 2 As shown, the dual-rotor motor 600 has a double-end output structure, the output end of the outer rotor 640 of the dual-rotor motor is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com