Microcosmic oil deposit model and manufacturing method and using method thereof

A technology of reservoir model and production method, which is applied in the fields of earthwork drilling, wellbore/well components, etc., can solve the problems of inability to realize reservoir simulation, and achieve the effect of shortening the time of research and experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

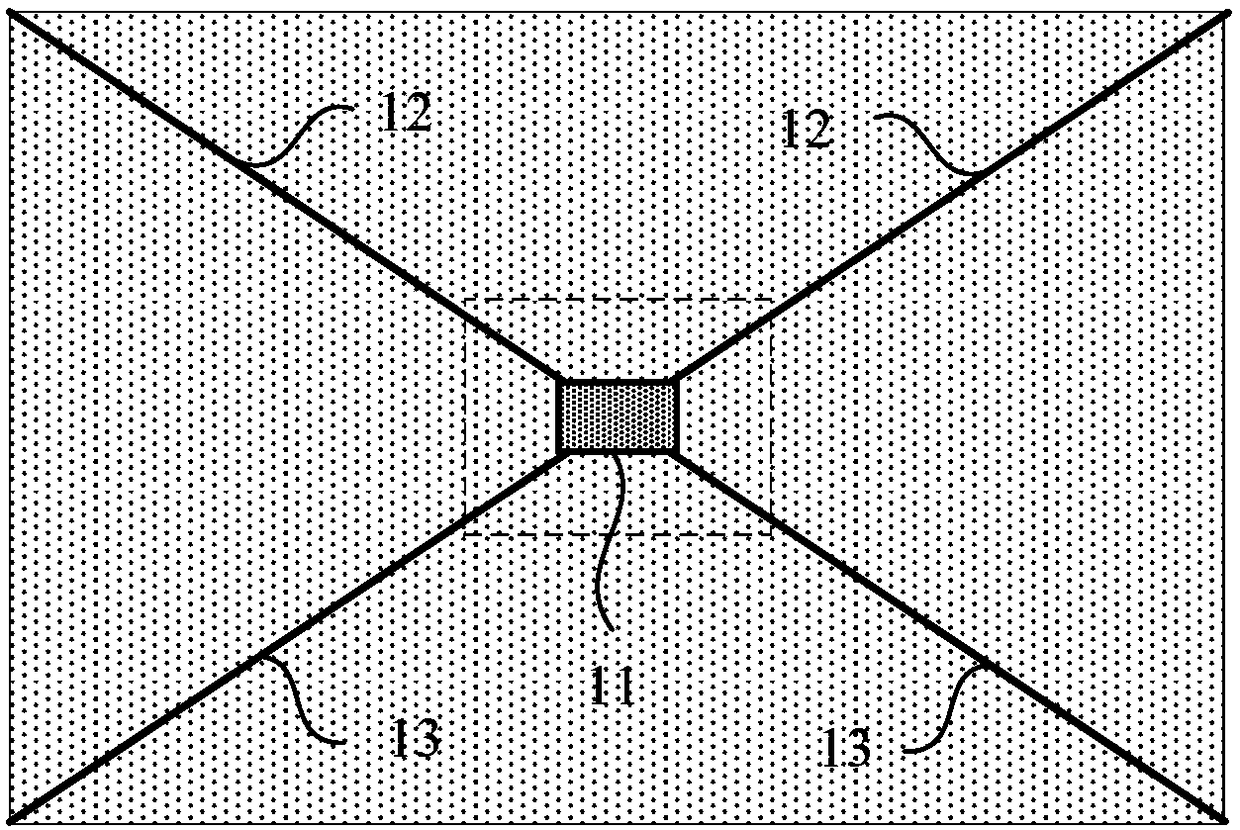

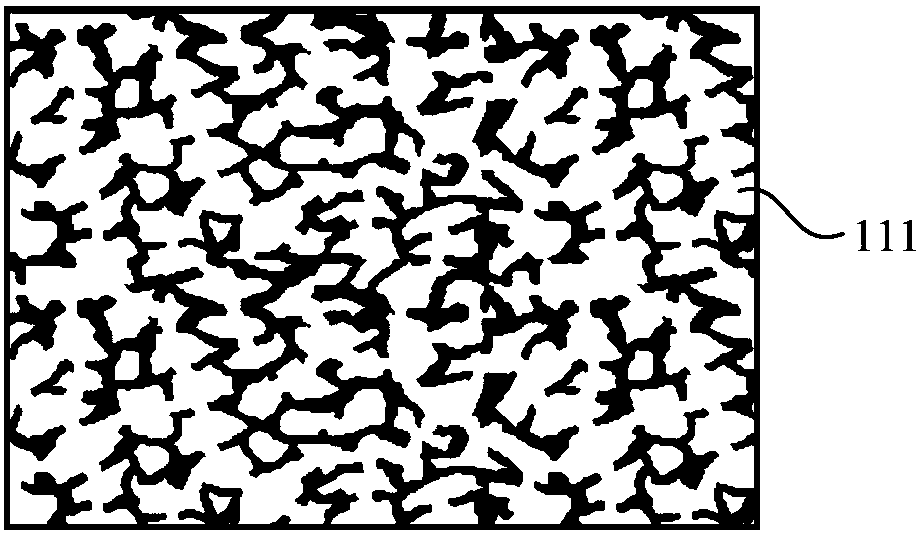

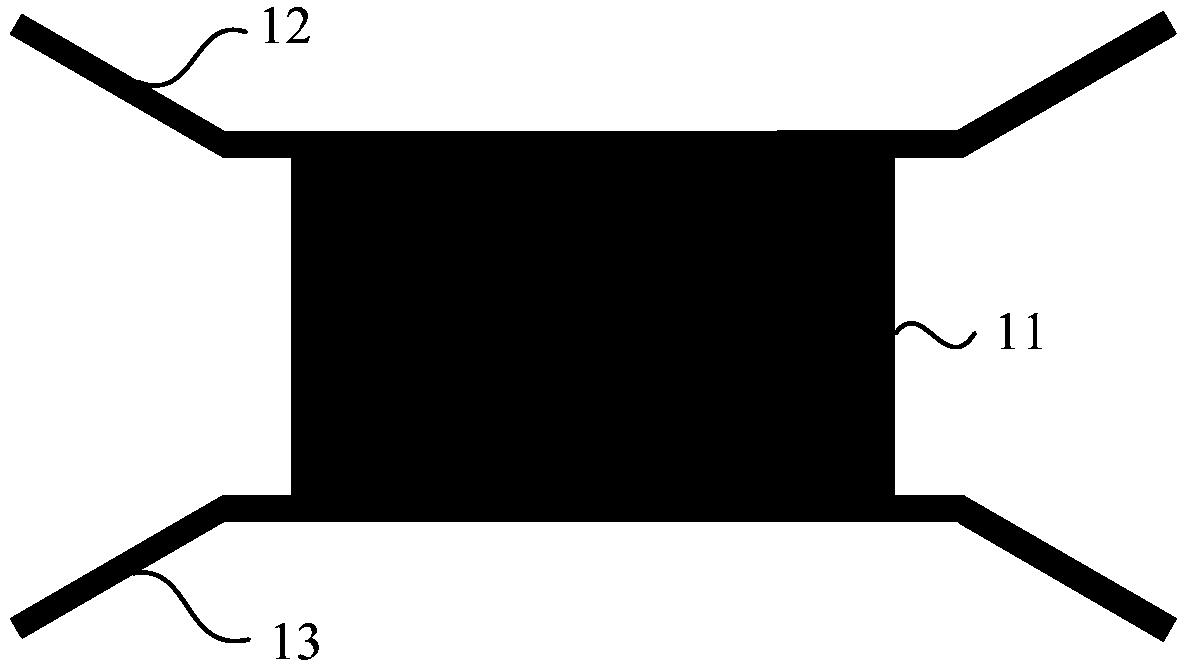

[0034] figure 1 It is a structural schematic diagram of a microscopic reservoir model provided by Embodiment 1 of the present invention, figure 2 yes figure 1 An enlarged schematic diagram of the skeleton of the model, refer to figure 1 and figure 2 , the reservoir model includes a model framework 11, a wetting phase channel 12 and a non-wetting phase channel 13, the model framework contains pore throat channels 111, the wetting phase channel 12 provides a flow channel for the wetting phase, and the non-wetting phase channel 13 provides flow channels for the non-wetting phase, the wetting phase channel 12 and the non-wetting phase channel 13 communicate with the pore throat channel 111 respectively, and the wetting phase channel 12 and the non-wetting phase channel 13 are respectively located at the two ends of the pore throat channel. side, wherein the diameters of the wetting phase channel 12 and the non-wetting phase channel 13 are larger than the minimum diameter of t...

Embodiment 2

[0044] Figure 5 It is a flow chart of a method for making a microscopic reservoir model provided in Embodiment 2 of the present invention. The method is used to make a microscopic reservoir model as described in any one of Embodiment 1. Refer to Figure 5 , the method specifically includes:

[0045] S100, using the first mask to etch the model substrate for the first time to form pore throat channels on the model substrate.

[0046] S120, use the second mask to etch the model substrate for the second time, and form a wetting phase channel and a non-wetting phase channel on the model substrate, wherein the wetting phase channel and the non-wetting phase channel are respectively connected with the holes The throat channel is connected, the wetting phase channel and the non-wetting phase channel are located on both sides of the pore throat channel respectively, and the diameters of the wetting phase channel and the non-wetting phase channel are larger than the smallest diameter...

Embodiment 3

[0075] Figure 13 It is a flowchart of a method for using a microscopic reservoir model provided by Embodiment 3 of the present invention. refer to Figure 13 , the method of use is based on the reservoir model described in any one of embodiment one, specifically comprising:

[0076] S200, cleaning the microscopic reservoir model with hydrochloric acid solution, sodium hydroxide solution and deionized water, and drying the microscopic reservoir model.

[0077] When using the microscopic reservoir model provided in Example 1 to carry out imbibition experiments, the reservoir model needs to be cleaned first to remove residual inorganic and organic impurities in the reservoir model and residual liquid in the preparation process, etc., and Keep the reservoir model dry when in use.

[0078] Specifically, the cleaning step may specifically be: inject 10% hydrochloric acid solution into the microscopic reservoir model at a speed of 1ml / min for 1h, inject 5% NaOH solution into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com