Preparation method and application of mixed valence manganese oxide/silver phosphate photocatalyst

A technology of manganese oxide and mixed valence states, applied in the field of photocatalysis, to achieve high-efficiency visible light catalytic degradation of pollutants in water, increase degradation rate, and improve low quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

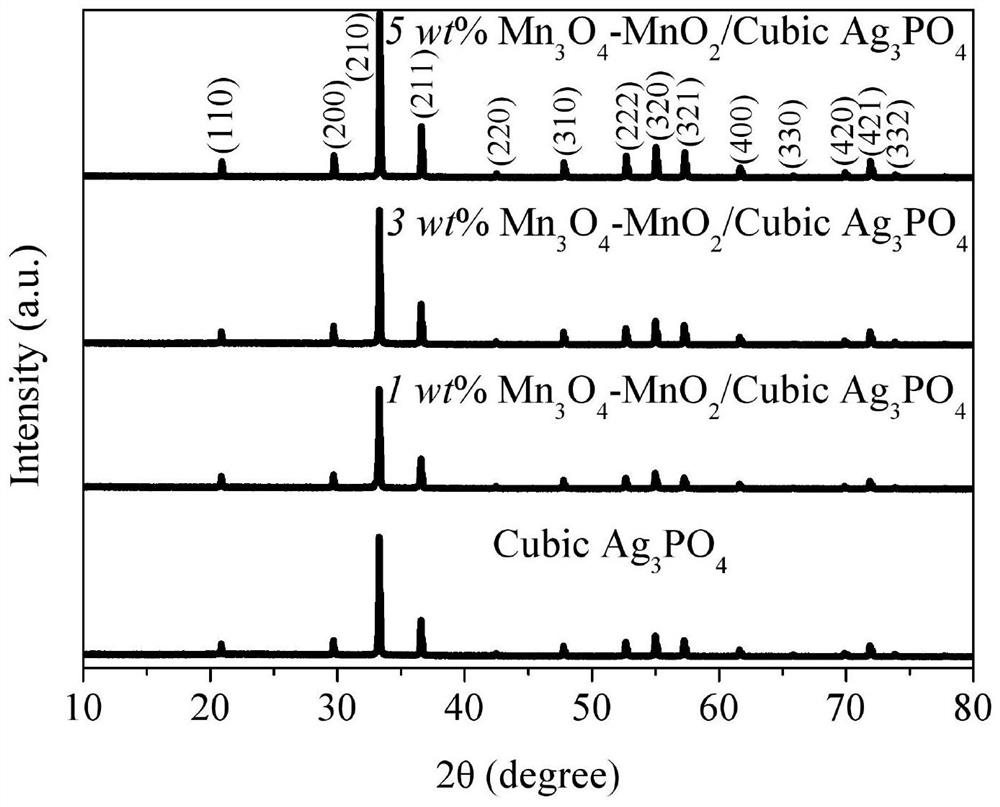

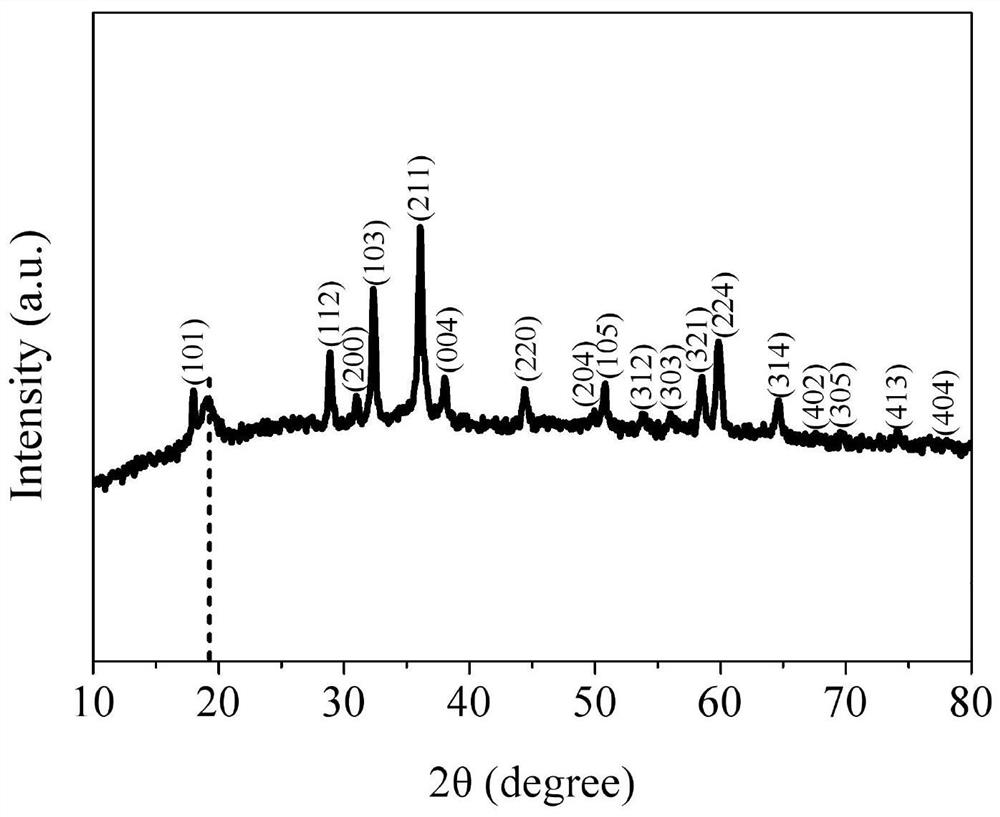

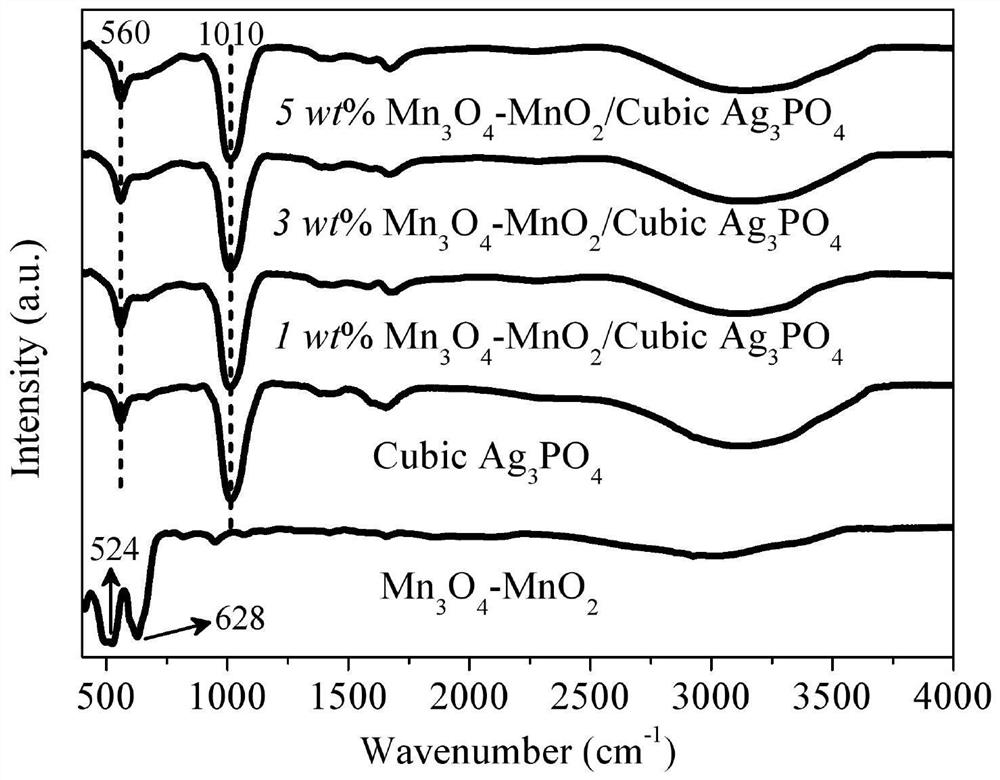

[0026] The invention provides a method for preparing a mixed valence manganese oxide / silver phosphate photocatalyst, the preparation method comprising:

[0027] (1) MnCl 2 4H 2 O. Mix PVP (polyvinylpyrrolidone) and the first water, then add NaOH solution, and add KMnO after 2-3min 4 solution, after stirring, filtering, washing and drying, Mn 3 o 4 -MnO 2 Nanosheets;

[0028] (2) PEG 2000 (polyethylene glycol 2000), Na 2 HPO 4 12H 2 O, Mn 3 o 4 -MnO 2 Mix the nanosheets with the second water, heat to 55-65°C after ultrasonication, then add silver ammonia solution, stir, filter, wash and dry to obtain mixed valence manganese oxide / silver phosphate photocatalyst (Mn 3 o 4 -MnO 2 / Cubic Ag 3 PO 4 composite photocatalyst).

[0029] In a preferred embodiment of the present invention, in order to further increase the photocatalytic efficiency of the composite photocatalyst that makes, with respect to the first water of 20mL, MnCl 2 4H 2 The amount of O is 0.8-1g, th...

Embodiment 1

[0043] 0.9gMnCl 2 4H 2 O, 1gPVP and 20mL of the first water (the temperature of the first water is 60°C) were mixed, then 4.5mL of 2mol / L NaOH solution was added, and 5mL of 0.2mol / L KMnO was added after 2min 4 solution, after stirring for 3 h, filtering, washing and drying at 60°, Mn 3 o 4 -MnO 2 nanosheets; 0.4g AgNO 3 Dissolve in 100 mL deionized water, drop into 26 wt % of dilute ammonia water until the precipitate just disappears to obtain a silver ammonia solution. Mix 5gPEG 2000, 7.16gNa 2 HPO 4 12H 2 O, 0.0062gMn 3 o 4 -MnO 2 Mix nanosheets with 90mL of second water, heat to 60°C after ultrasonication, then add silver ammonia solution, stir for 60min, filter, wash and dry at 60° to obtain Mn 3 o 4 -MnO 2 / Cubic Ag 3 PO 4 Composite photocatalyst A1; in Mn 3 o 4 -MnO 2 / CubicAg 3 PO 4 Composite photocatalyst A1, Mn 3 o 4 -MnO 2 has a quality score of 3 wt %, Cubic Ag 3 PO 4 has a quality score of 97 wt %, the sample is marked as 3 wt % ...

Embodiment 2

[0045] 0.9gMnCl 2 4H 2 O, 1gPVP and 20mL of the first water (the temperature of the first water is 60°C) were mixed, then 4.5mL of 2mol / L NaOH solution was added, and 5mL of 0.2mol / L KMnO was added after 2min 4 solution, after stirring for 3 h, filtering, washing and drying at 60°, Mn 3 o 4 -MnO 2 nanosheets; 0.4g AgNO 3 Dissolve in 100 mL deionized water, drop into 26 wt % of dilute ammonia water until the precipitate just disappears to obtain a silver ammonia solution. Mix 5gPEG 2000, 7.16gNa 2 HPO 4 12H 2 O, 0.0020gMn 3 o 4 -MnO 2 Mix nanosheets with 90mL of second water, heat to 60°C after ultrasonication, then add silver ammonia solution, stir for 60min, filter, wash and dry at 60° to obtain Mn 3 o 4 -MnO 2 / Cubic Ag 3 PO 4 Composite photocatalyst A2; in Mn 3 o 4 -MnO 2 / CubicAg 3 PO 4 Composite photocatalyst A2, Mn 3 o 4 -MnO 2 has a quality score of 1 wt %, Cubic Ag 3 PO 4 has a quality score of 99 wt %, the sample is marked as 1 wt % Mn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com