Preparation method and application of a decatungstate/carbon nitride composite photocatalyst

A technology of decapolytungstate and photocatalyst, which is applied in the field of photocatalysis and achieves the effects of simple preparation method, improved photocatalytic efficiency and favorable industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

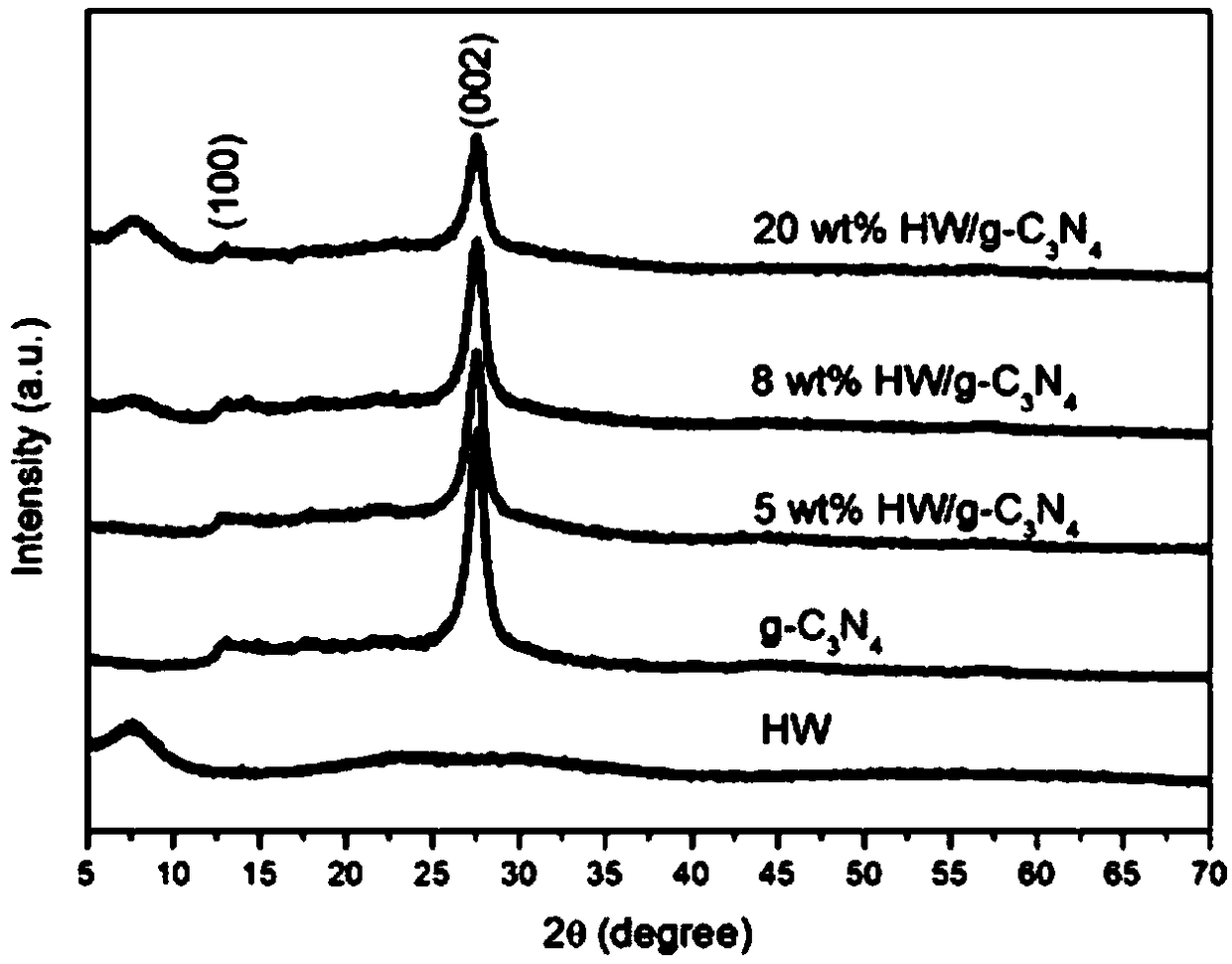

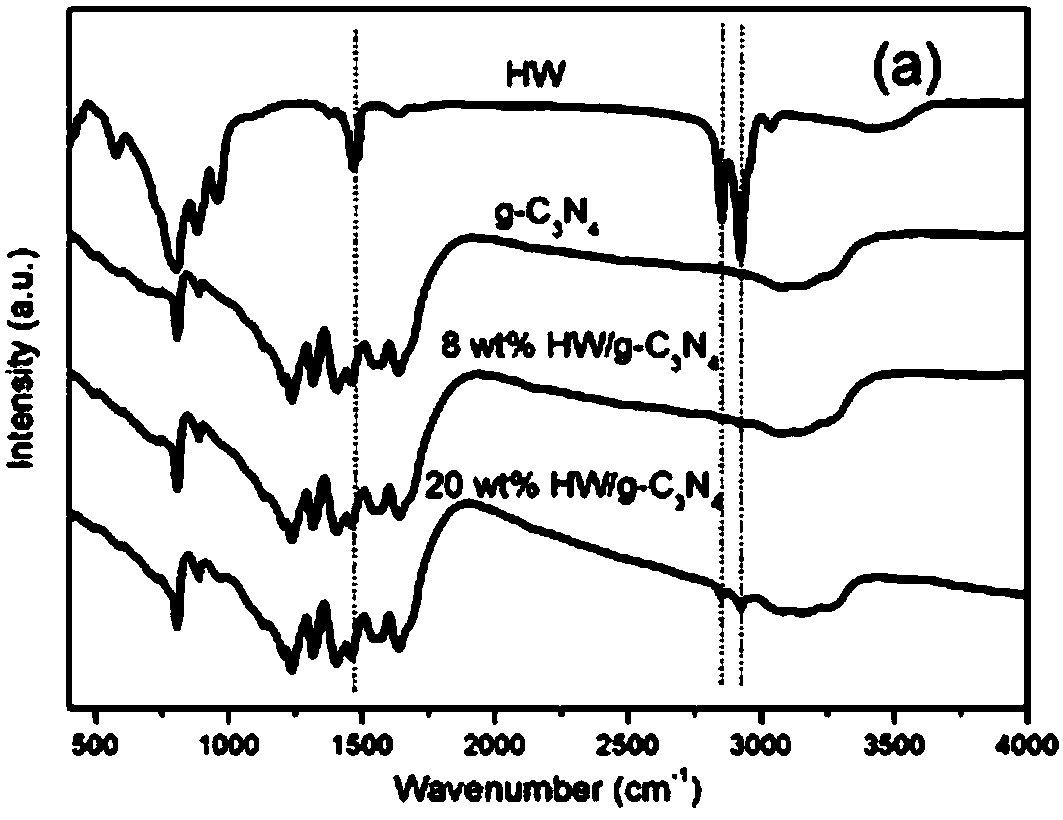

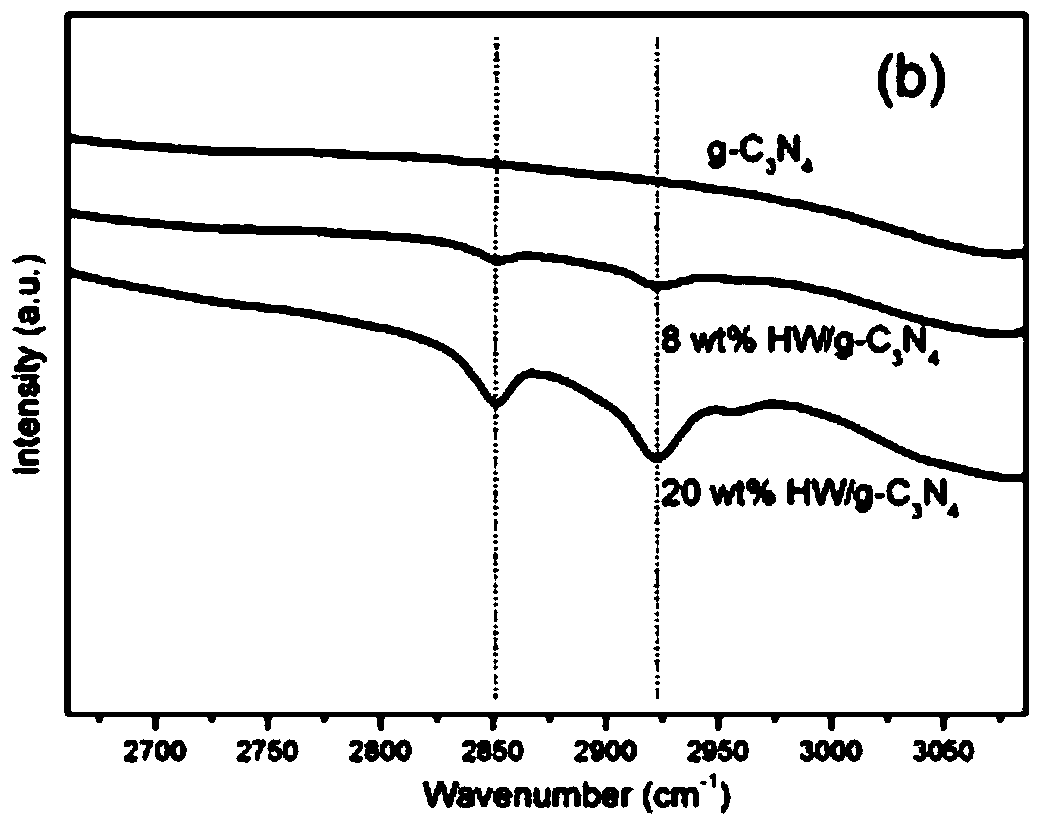

[0024]Embodiment 1 The present invention consists of HW and g-C 3 N 4 Composition, the mass fraction of the HW is 5wt% ~ 20wt%, the g-C 3 N 4 The mass fraction of is 80wt%~95wt%, and its specific preparation method comprises the following steps:

[0025] (1) Add 0.01mol (3.3g) Na to a 250mL round bottom flask successively 2 WO 4 2H 2 O and 4mL H 2 O, boil for 5min, add 6.9mL 3M HCl, add 0.003mol (1.46g) CTAB dissolved in 4mL water / ethanol under constant stirring, keep the temperature at 100°C, reflux for 10min, wash with deionized water / ethanol after the reaction The product was dried at 50°C;

[0026] (2) Put melamine in a covered crucible, heat up to 550°C in a muffle furnace at a heating rate of 2.3°C / min, keep it for 4 hours, and the yellow powder obtained after natural cooling is the block g-C 3 N 4 ;

[0027] (3) HW and g-C obtained in steps (1), (2) 3 N 4 Disperse in 50mL methanol respectively, ultrasonication for 1h, mix the suspension with ultrasonication ...

Embodiment 2

[0031] Embodiment 2 prepares the mass fraction containing HW to be 5wt%HW / g-C 3 N 4 catalyst of light.

[0032] Follow the steps below:

[0033] (1) Add 0.01mol (3.3g) Na to a 250mL round bottom flask successively 2 WO 4 2H 2 O and 4mL H 2 O, boil for 5min, add 6.9mL 3M HCl, add 0.003mol (1.46g) CTAB dissolved in 4mL water / ethanol under constant stirring, keep the temperature at 100°C, reflux for 10min, wash with deionized water / ethanol after the reaction The product was dried at 50°C;

[0034] (2) Put melamine in a covered crucible, heat up to 550°C in a muffle furnace at a heating rate of 2.3°C / min, keep it for 4 hours, and the yellow powder obtained after natural cooling is the block g-C 3 N 4 ;

[0035] (3) 0.05g of HW and 0.95g of g-C obtained in steps (1) and (2) 3 N 4 Disperse in 50mL of methanol respectively, sonicate for 1h, mix and sonicate the suspension and put it in a fume hood to volatilize for 2h. After the methanol solution is evaporated to dryness,...

Embodiment 3

[0038] Example 3 Preparation of HW / g-C containing HW mass fraction of 20wt% 3 N 4 composite photocatalyst.

[0039] Follow the steps below:

[0040] (1) Add 0.01mol (3.3g) Na to a 250mL round bottom flask successively 2 WO 4 2H 2 O and 4mL H 2 O, boil for 5min, add 6.9mL 3M HCl, add 0.003mol (1.46g) CTAB dissolved in 4mL water / ethanol under constant stirring, keep the temperature at 100°C, reflux for 10min, wash with deionized water / ethanol after the reaction The product was dried at 50°C;

[0041] (2) Put melamine in a covered crucible, heat up to 550°C in a muffle furnace at a heating rate of 2.3°C / min, keep it for 4 hours, and the yellow powder obtained after natural cooling is the block g-C 3 N 4 ;

[0042] (3) 0.20g of HW and 0.80g of g-C obtained in steps (1) and (2) 3 N 4 Disperse in 50mL of methanol respectively, sonicate for 1h, mix and sonicate the suspension and put it in a fume hood to volatilize for 2h. After the methanol solution is evaporated to dryn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com