Low-spatter short-circuit gas shielded welding equipment

A gas shielded welding and equipment technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of high cost, shortened life, wear of wire feed wheel, etc., to improve the precision of pulse wire feeding and improve the welding effect , The effect of reducing the amount of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

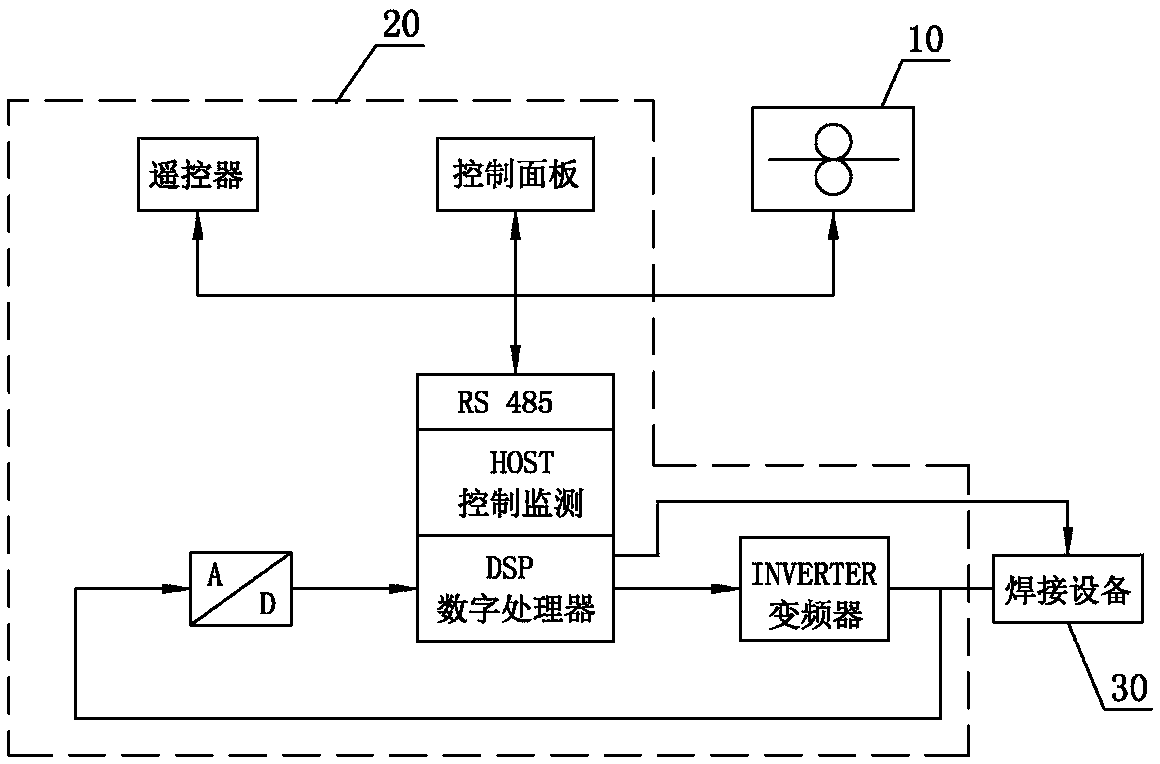

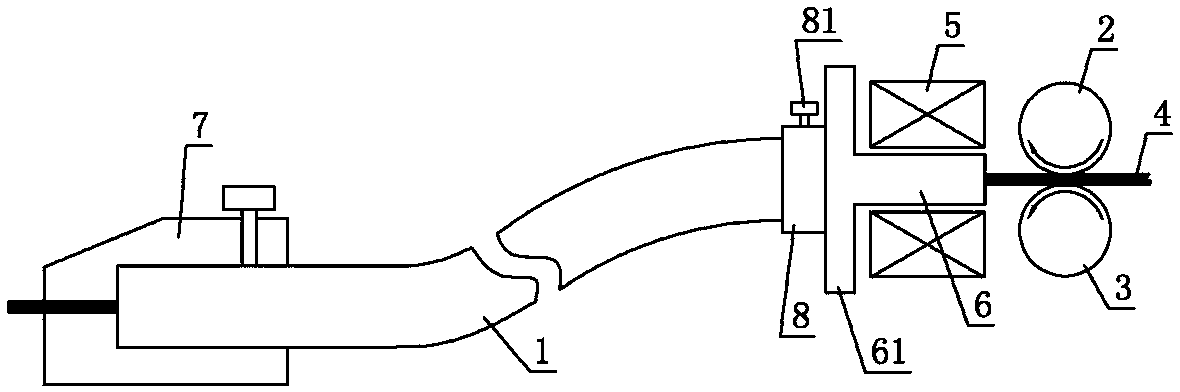

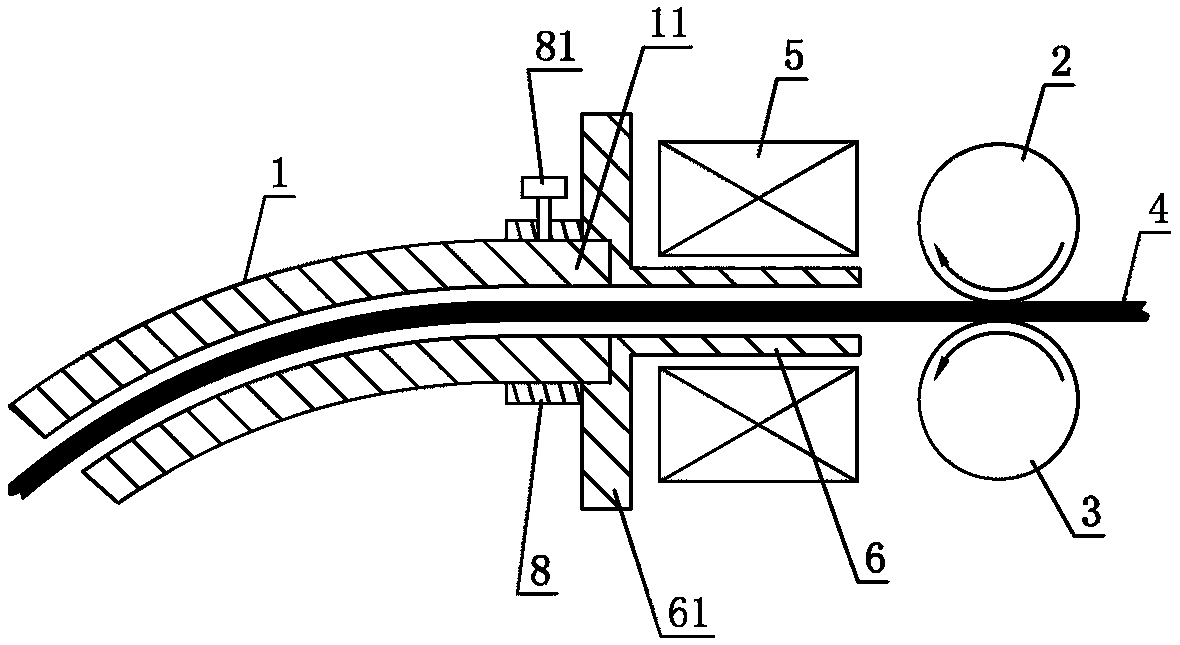

[0016] The working principle of the cold metal transition welding technology is to monitor the short-circuit transition process through the digital welding control system 20. When the digital welding control system 20 detects a short-circuit signal, it will feed back to the pulse wire feeding device, and the pulse wire feeding device quickly retracts the welding wire. In this way, the welding wire is separated from the droplet. At the same time, during the droplet separation and transition process, the digital welding control system 20 controls the current value loaded on the welding wire 4 to be almost zero, and the heat input is also almost zero at this time, which is greatly reduced. The welding heat input is reduced, so the cold metal transition welding technology is widely used in the welding field. In this embodiment, the pulsed wire feeding device is improved on the basis of the cold metal transfer welding technology, so that the cold metal transfer welding technology ca...

Embodiment 2

[0020] The difference between this embodiment and the first embodiment is that the wire feeding tube 1 described in this embodiment is a plastic hose, and the plastic hose will be in a state of natural bending with the welding process and its own gravity during use. The rest of the structures and usage methods are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0022] like figure 1 and figure 2 As shown, the difference between this embodiment and the first embodiment is that: a shoulder 61 made of magnetic material is provided at the front end of the guide tube 6, wherein the magnetic material can be metal materials such as iron. The rest of the structures and usage methods are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com