A welding torch system and welding method suitable for welding medium and thick plates

A technology of welding torch and welding torch clamp, which is applied in the field of welding torch system for medium and thick plate welding, which can solve the problems of low welding efficiency, poor welding performance, slag leakage and molten iron leakage, etc. Forming beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

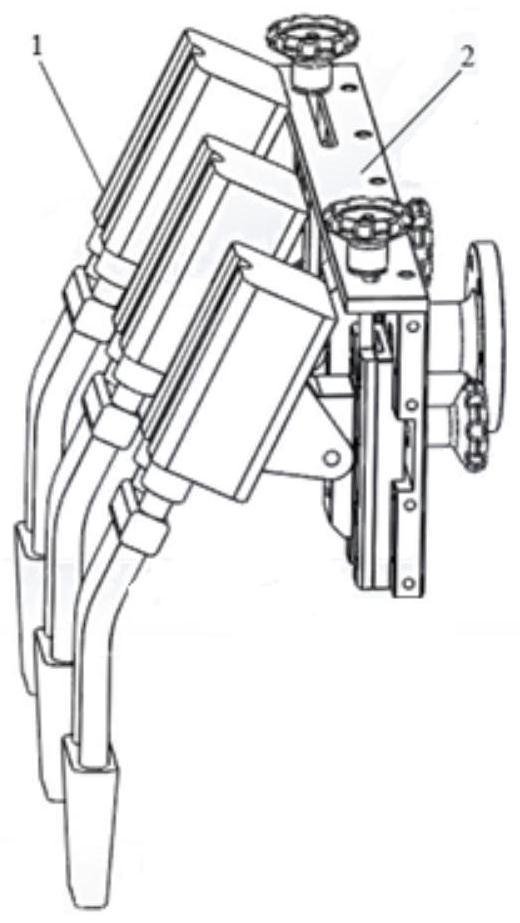

[0077] Embodiment 1: This embodiment provides a high-efficiency welding torch system suitable for welding medium and thick plates, and the system includes a twin-wire welding torch assembly 11 and a welding torch clamp 2 .

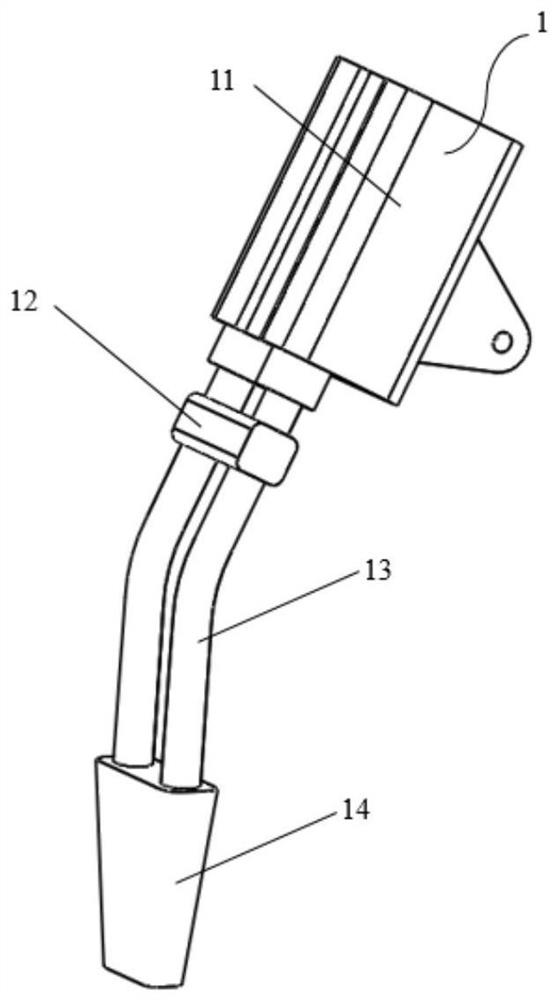

[0078] See figure 1 , the above-mentioned twin-wire type welding torch assembly 1, which includes a welding torch seat 11, a fixing fixture 12, a welding torch barrel 13 and a welding torch head 14;

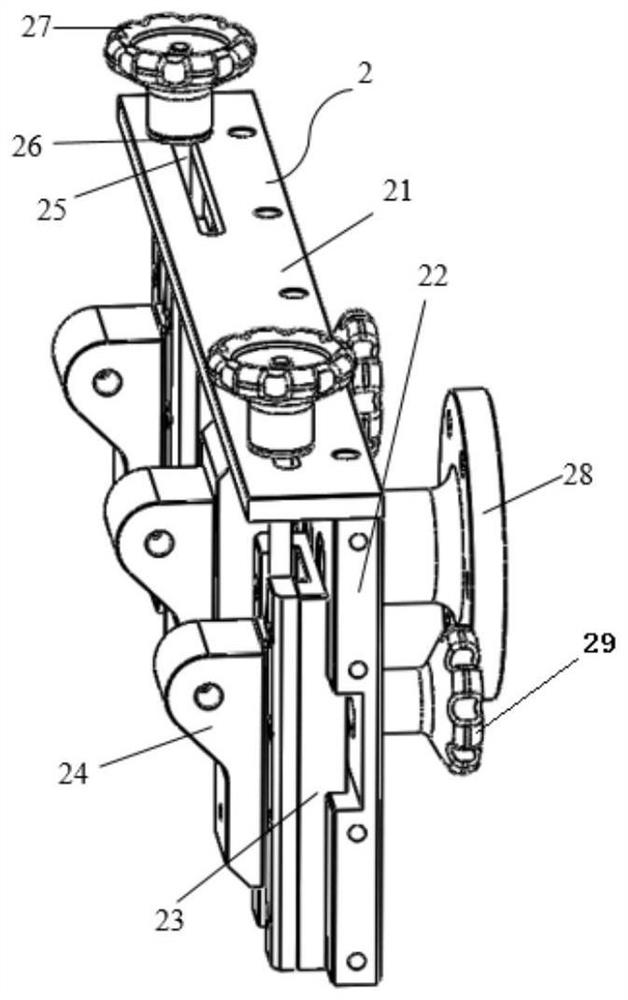

[0079] See figure 2 , the first fixed plate 21, the seat plate 22, the sliding seat 23, the welding torch connecting body 24, the lifting screw 25, the pressure plate 26, the first hand wheel 27, the flange connecting body 28 and the second hand wheel of the welding torch fixture 2 29; Specifically, the first fixing plate 21 of the welding torch clamp 2 is vertically connected with the seat plate 22, the sliding seat 23 of the welding torch clamp 2 is assembled in the rail slide groove of the seat plate 22, and the second fixing plate 21 of the welding torc...

Embodiment 2

[0081] Embodiment 2: A welding method for butt welding a 30 mm thick steel plate using a high-efficiency welding torch system.

[0082] This embodiment provides a welding method, using the welding system described in Embodiment 1 to implement the welding method, the method includes the following steps:

[0083] (1) Adjust the horizontal distance between three double-wire welding torches through the second hand wheel behind the sliding seat plate, the horizontal distance between adjacent double-wire welding torches is equal, and uniformly adjusted to 200mm;

[0084] (2) By turning the first handwheel above the first fixing plate, adjust the vertical distance between the three double-wire welding torches, the vertical distance between adjacent double-wire welding torches is equal, and uniformly adjusted to 10mm;

[0085] (3) By adjusting the angles of the three twin-wire welding guns, keep them on a horizontal line, and the welding torch heads of the three twin-wire welding guns...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com