Vitrified Bond Abrasives

A vitrified bond and abrasive tool technology, which is applied in abrasives, manufacturing tools, metal processing equipment, etc., can solve the problems of moderate consumption of bonding materials and self-sharpening of abrasive tools, so as to maintain mechanical strength and water resistance, reduce Sintering temperature, effect of low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

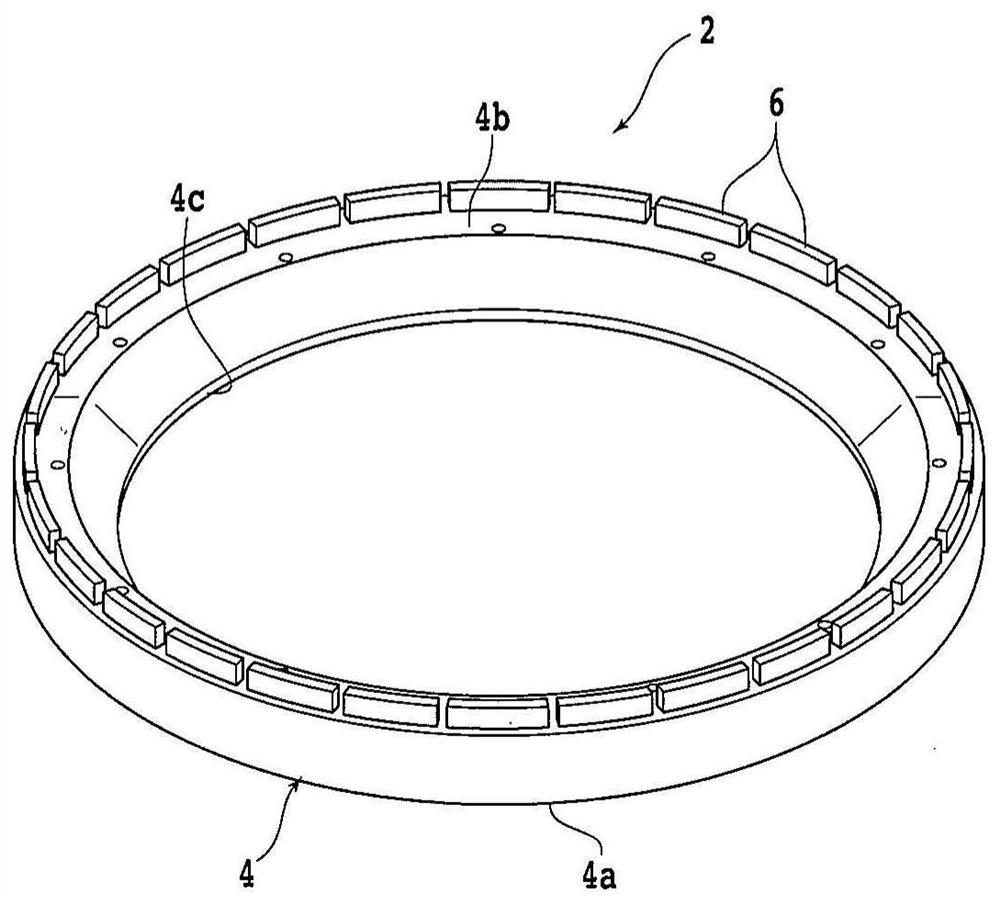

Image

Examples

Embodiment

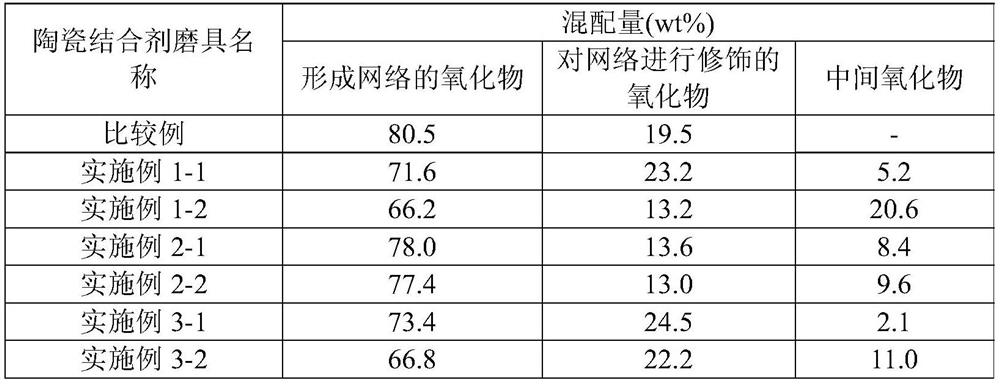

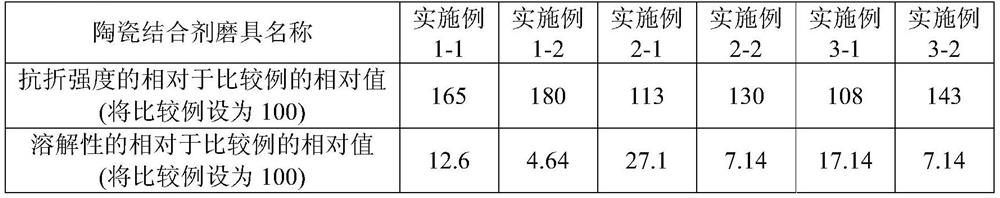

[0035] In the present embodiment, for containing by ZnO and Zr 2 o 3 The intermediate oxide composed of ZnO, or the intermediate oxide composed of Zr 2 o 3 A vitrified bonded abrasive tool composed of an intermediate oxide is produced by changing the intermediate oxide and its compounding amount. For each intermediate oxide, two types were produced by changing the compounding amount, and a total of 6 types of vitrified bonded abrasive tools were produced. In addition, the water resistance and flexural strength of each produced vitrified bonded abrasive tool were tested.

[0036] will contain ZnO and Zr 2 o 3 The names of the vitrified bonded abrasive tools of the formed intermediate oxides are described as "Example 1-1" and "Example 1-2", respectively. The names of the vitrified bonded abrasives containing the intermediate oxide composed of ZnO are respectively referred to as "Example 2-1" and "Example 2-2". will contain the Zr 2 o 3 The names of the vitrified bonded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com