Air guide device and method for reducing air pressure drag through air guide device

A technology of air diversion and air pressure, applied in the direction of aerodynamic improvement, streamlined body, transportation and packaging, etc., to achieve the effect of reducing air pressure difference, broad application prospects, and weakening pressure difference resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

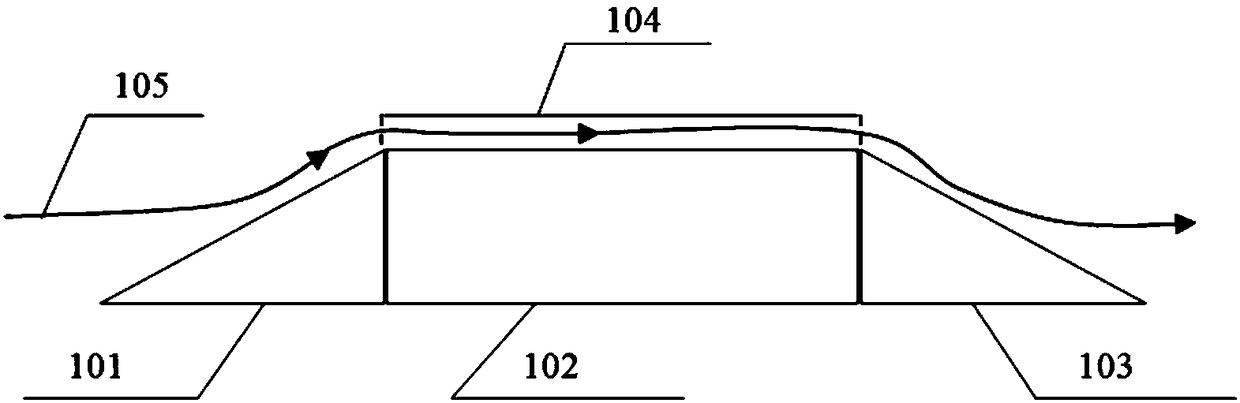

[0024] An air guide device and method for reducing air pressure differential resistance when a high-speed moving body moves, such as figure 1 As shown, the ventilation duct 104 is arranged on the surface close to the high-speed moving body, along the direction of motion, the air inlet of the pipeline is positioned at the front end (head 104) of the high-speed moving body, and the air outlet is positioned at the rear end (tail portion 103) of the high-speed moving body .

[0025] Concrete device and method are as follows:

[0026] air guide as figure 1 As shown, the high-speed moving body in the air includes a head 101 , a middle 102 and a tail 103 . A guide channel (ventilation duct 104) is arranged on the top of the moving body. When the moving body moves at a high speed in the air, the head air 105 is squeezed into the diversion channel, and the extruded gas diffuses at the tail through the diversion channel to fill the tail vacuum area caused by the extrusion of the movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com