Water-based gravure surface printing matte ink for plastic film and preparation method thereof

A plastic film and matte ink technology, which is applied in the field of ink, can solve the problem of water-based gravure plastic film surface printing matte ink not meeting environmental protection requirements and printing effect, poor leveling of solvent-based surface printing matte ink, water-based ink transfer Insufficient and other problems, to achieve good adhesion fastness, good leveling, good fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

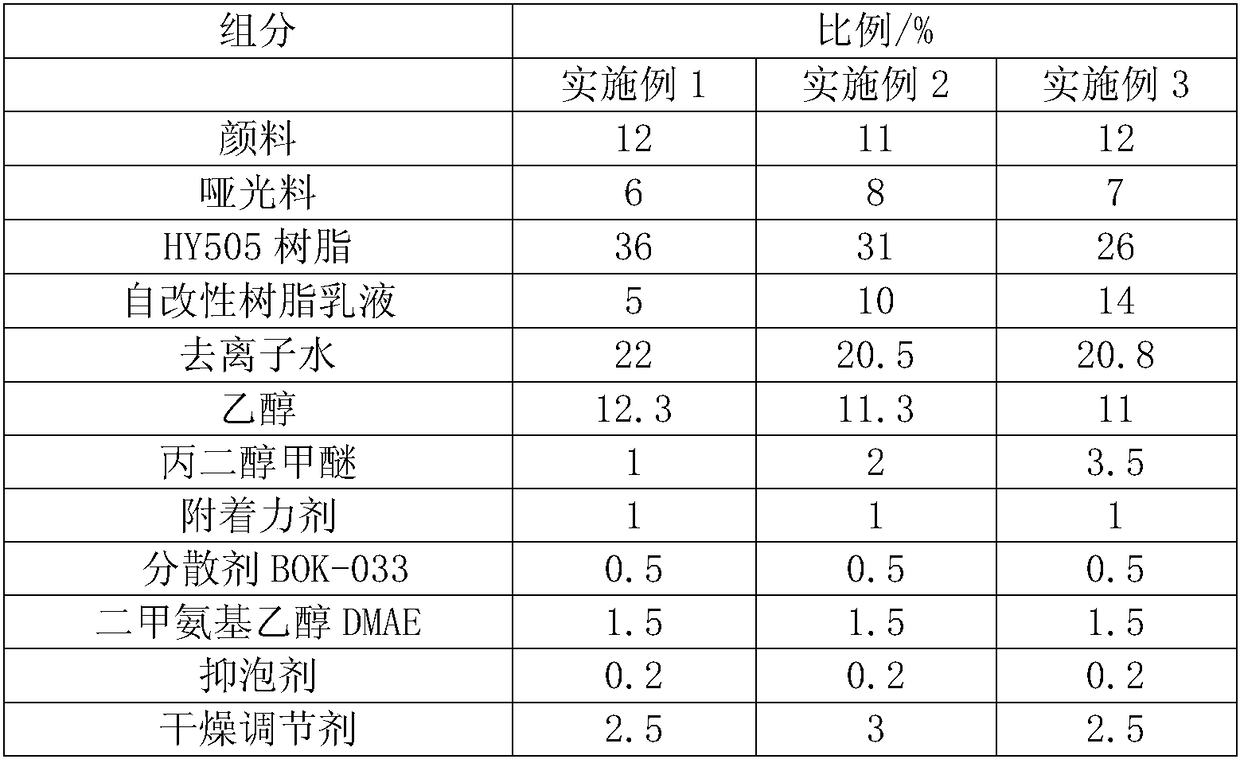

[0028] Adopt the components and proportions shown in Table 1 respectively

[0029] The preparation methods are as follows: except the adhesion agent, antifoaming agent, drying regulator and 9% deionized water, the rest of the resin emulsion and solvent are first stirred evenly, and then the pigment and matte material are added and the stirring is continued. Uniform; the mixed components are then ground by a grinder, and the grinding is stopped after the fineness reaches # The cup is 20-28 seconds / 25°C, the pH value is between 8.0-9.0, and finally filtered and packaged.

[0030] Printing requirements: printing speed: 150-240 m / min;

[0031] Gravure depth: 30-45 microns;

[0032] Drying temperature: 45-55°C;

[0033] Printing viscosity: 11-15 seconds / 25°C / thin-walled 3# Zahn cup.

[0034] Components and ratios thereof of the printing ink of table 1 embodiment 1-3

[0035]

[0036] Among them, the "self-modifying resin emulsion" in Table 1 is obtained by emulsifying and mi...

Embodiment 4

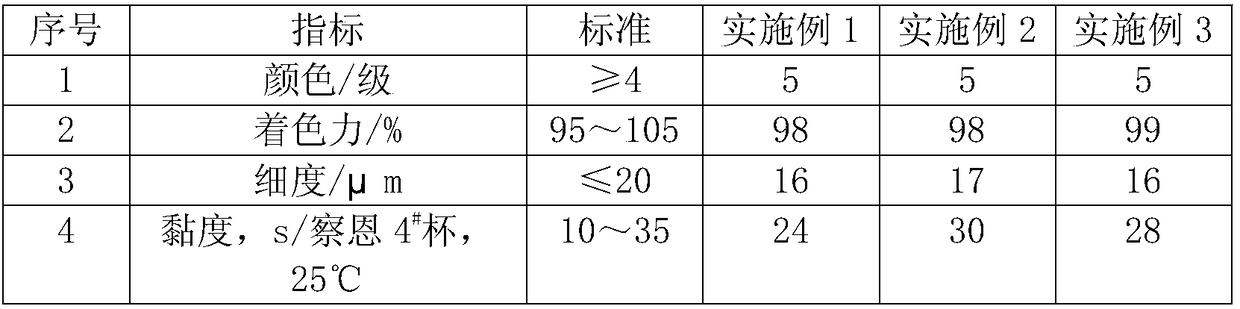

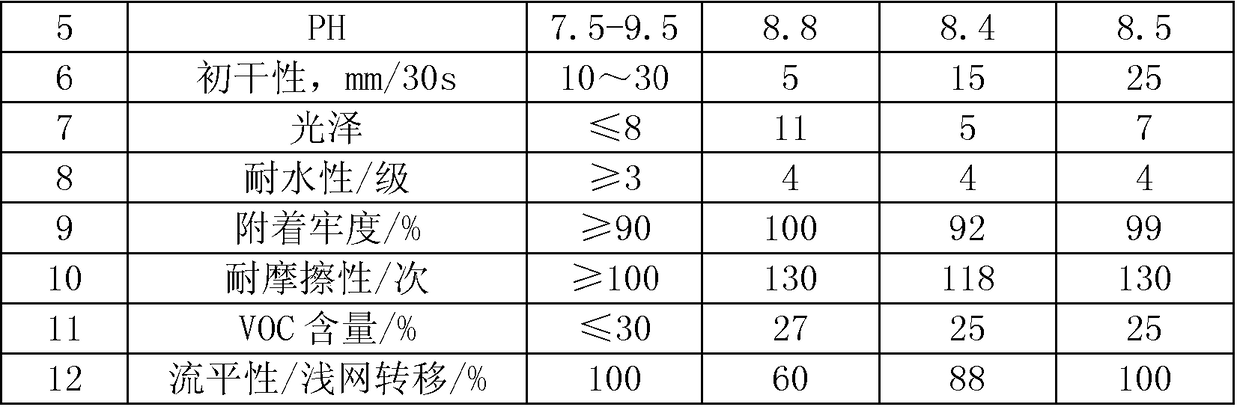

[0038] The product of embodiment 1-3 gained is carried out index detection respectively, and its result is as shown in table 2:

[0039] Each index standard and the index detection result of the product of the present invention.

[0040]

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com