Method and system for coupling charging bucket pressure-equalizing coal gas recovery and blast-furnace gas dry dust removal

A blast furnace gas and dry dust removal technology, which is applied in blast furnaces, dust collectors, blast furnace details, etc., can solve the problems of incapability of mutual backup, large construction investment and operating costs, inability to clean gas into the gas pipe network, etc. Construction and production and operation costs, reducing repeated construction investment costs, and saving the use of heat tracing steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

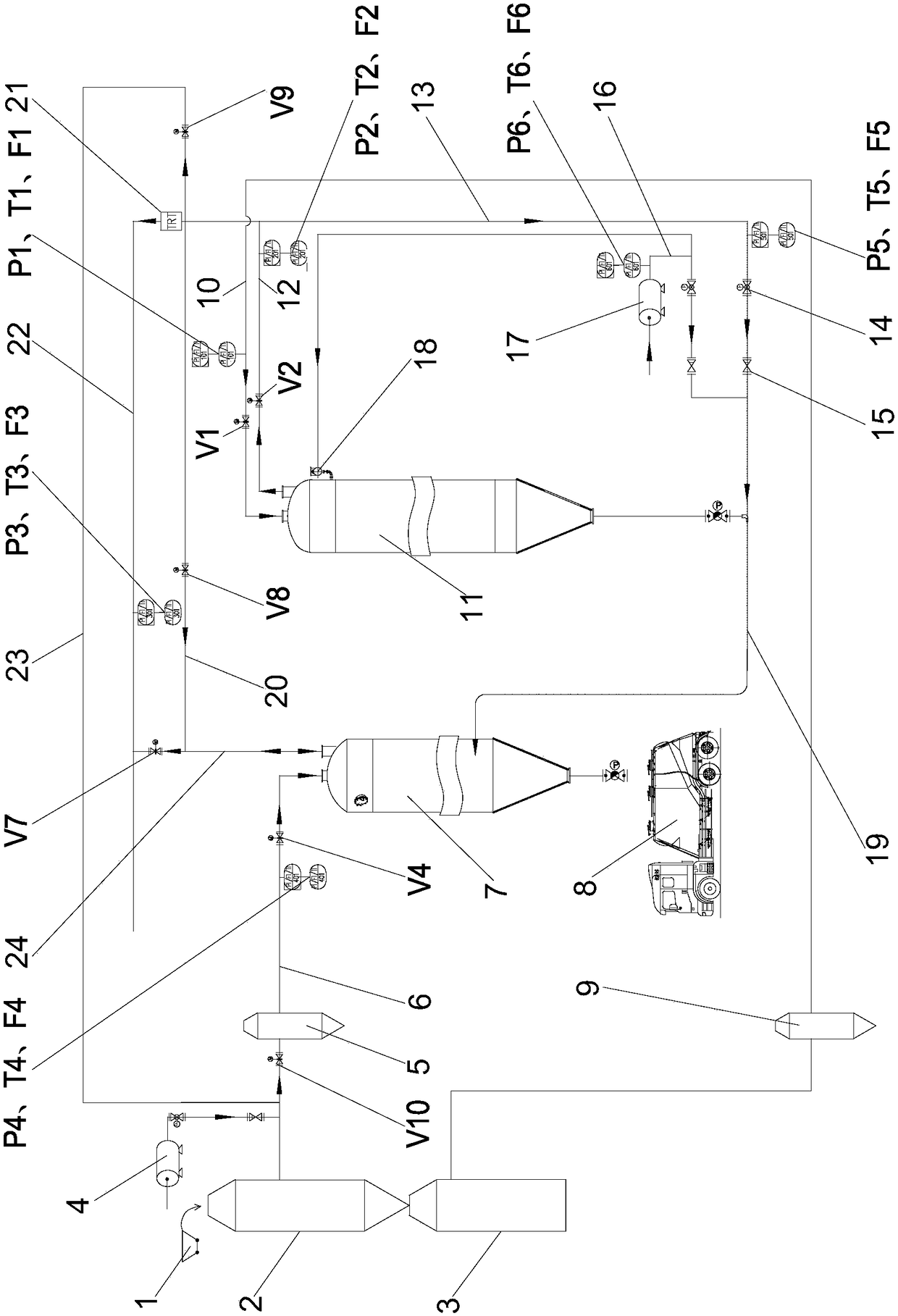

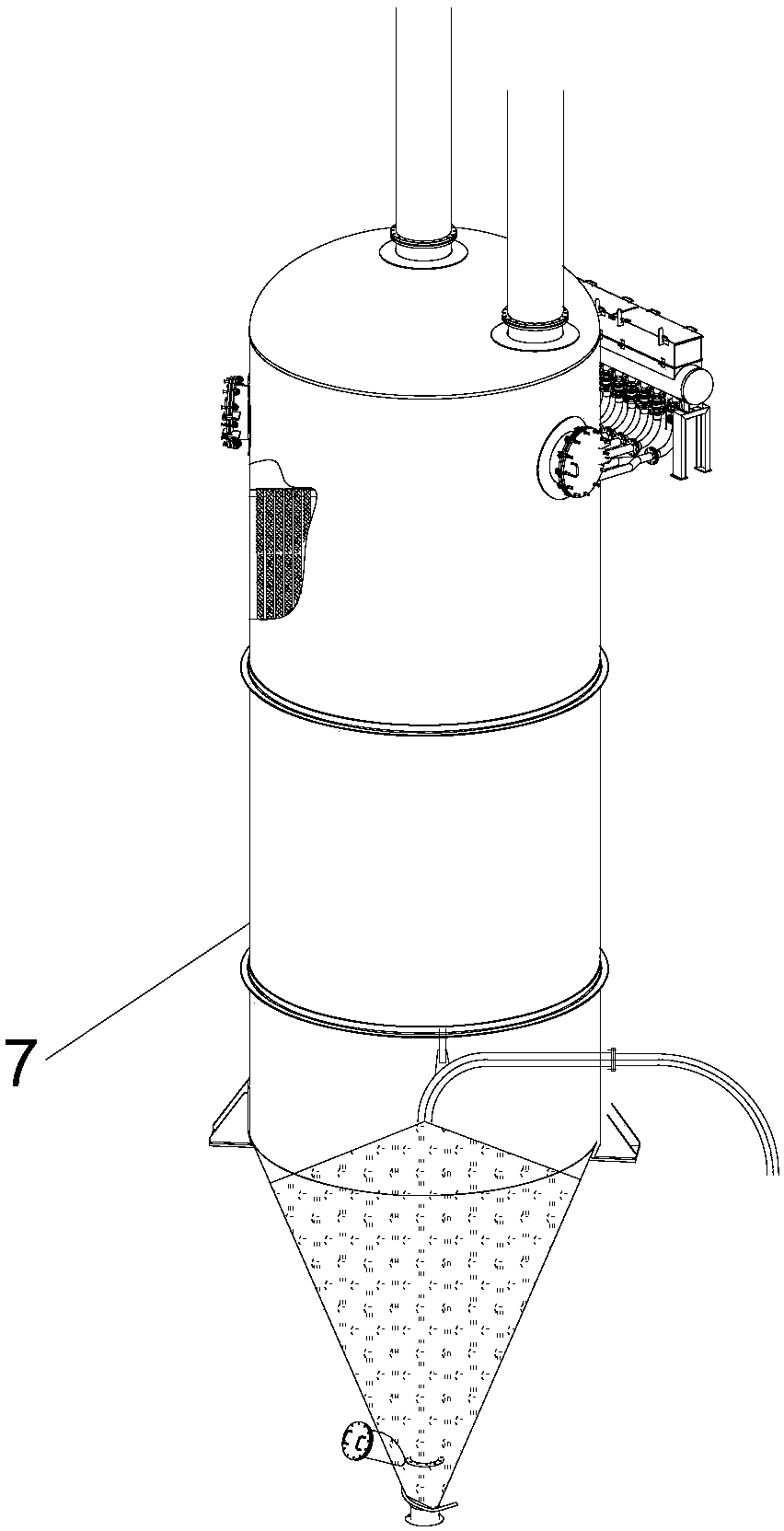

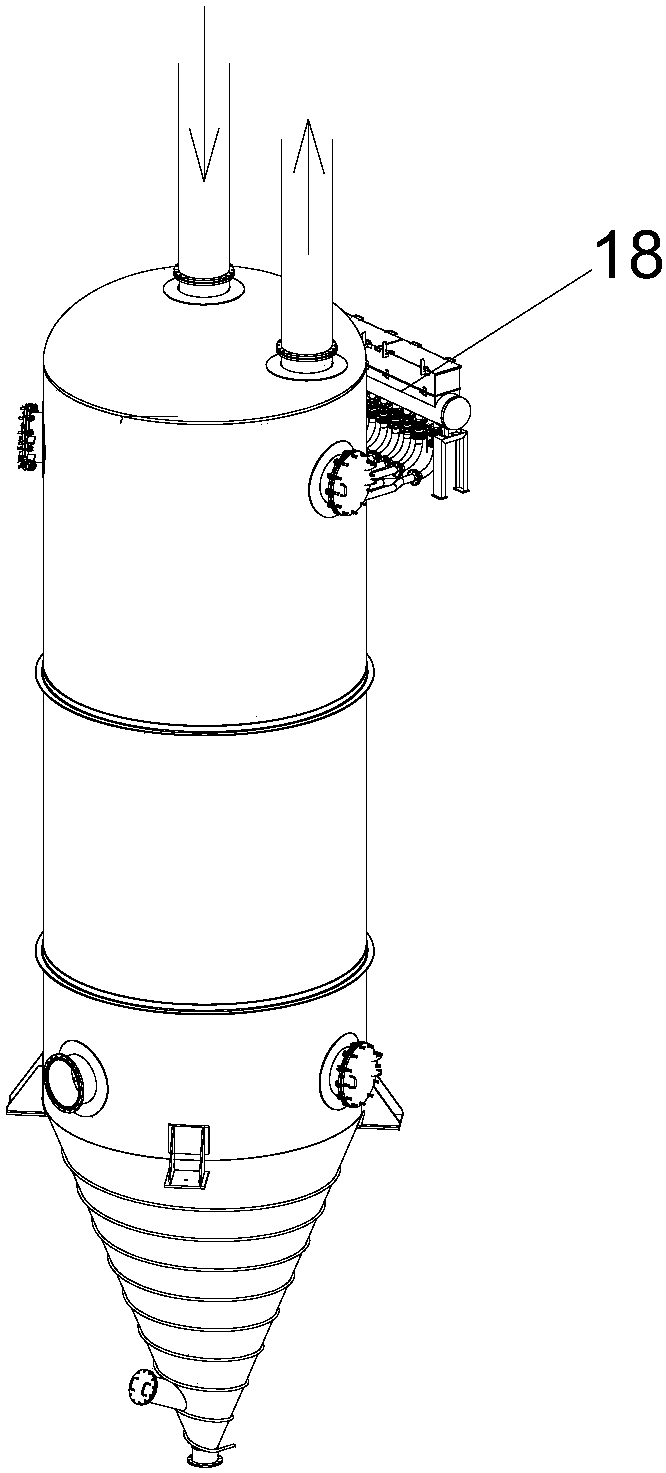

[0043] Such as Figure 1 to Figure 8 As shown, the present invention provides a coupling system for recovery of material tank pressure equalizing gas and blast furnace gas dry dedusting, which includes: furnace top pressure equalizing gas recovery device 7, the inlet at its upper end is connected with material tank 2, and the outlet at its upper end It is connected with the gas pipe network 22, and its lower end is provided with an ash unloading port, and its side wall is provided with an ash delivery port; the blast furnace gas dry dust removal device 11, its inlet is connected with the blast furnace 3 located below the material tank 2, and its outlet passes through The blast furnace gas residual pressure turbine power generation device 21 (i.e. TRT) is connected to the gas pipe network 22, and its lower end is provided with an ash discharge port. The ash discharge port of the blast furnace gas dry dust removal device 11 passes through the ash delivery pipe 19 (i.e. Ash Conve...

Embodiment approach 2

[0058] The present invention also provides a coupling method for the recovery of pressure-equalized gas from material tanks and dry dedusting of blast furnace gas. The structure, working principle and beneficial effects of the coupling system of tank equalized gas recovery and blast furnace gas dry dedusting are the same as those of Embodiment 1, and will not be repeated here. The method for coupling the pressure equalized gas recovery of the material tank and the dry dust removal of the blast furnace gas comprises the following steps:

[0059] Step a: Recover the raw gas in the material tank 2 to the furnace top pressure equalization gas recovery device 7 for filtration, and directly transport the filtered clean gas to the gas pipe network 22, and recover the gas discharged from the blast furnace 3 to the blast furnace gas dry filter in the dust removal device 11, and transport a part of the filtered clean gas to the gas pipe network 22 after being depressurized by the blast ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com