A kind of preparation method of magnesium alloy anti-corrosion composite film

A magnesium alloy, anti-corrosion technology, applied in anti-corrosion coatings, metal material coating processes, coatings, etc., can solve the problems of poor corrosion resistance and composite ability of chemical conversion coatings, and improve the overall adhesion and compactness. Avoid the effects of loose pores, poor adhesion and strong adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

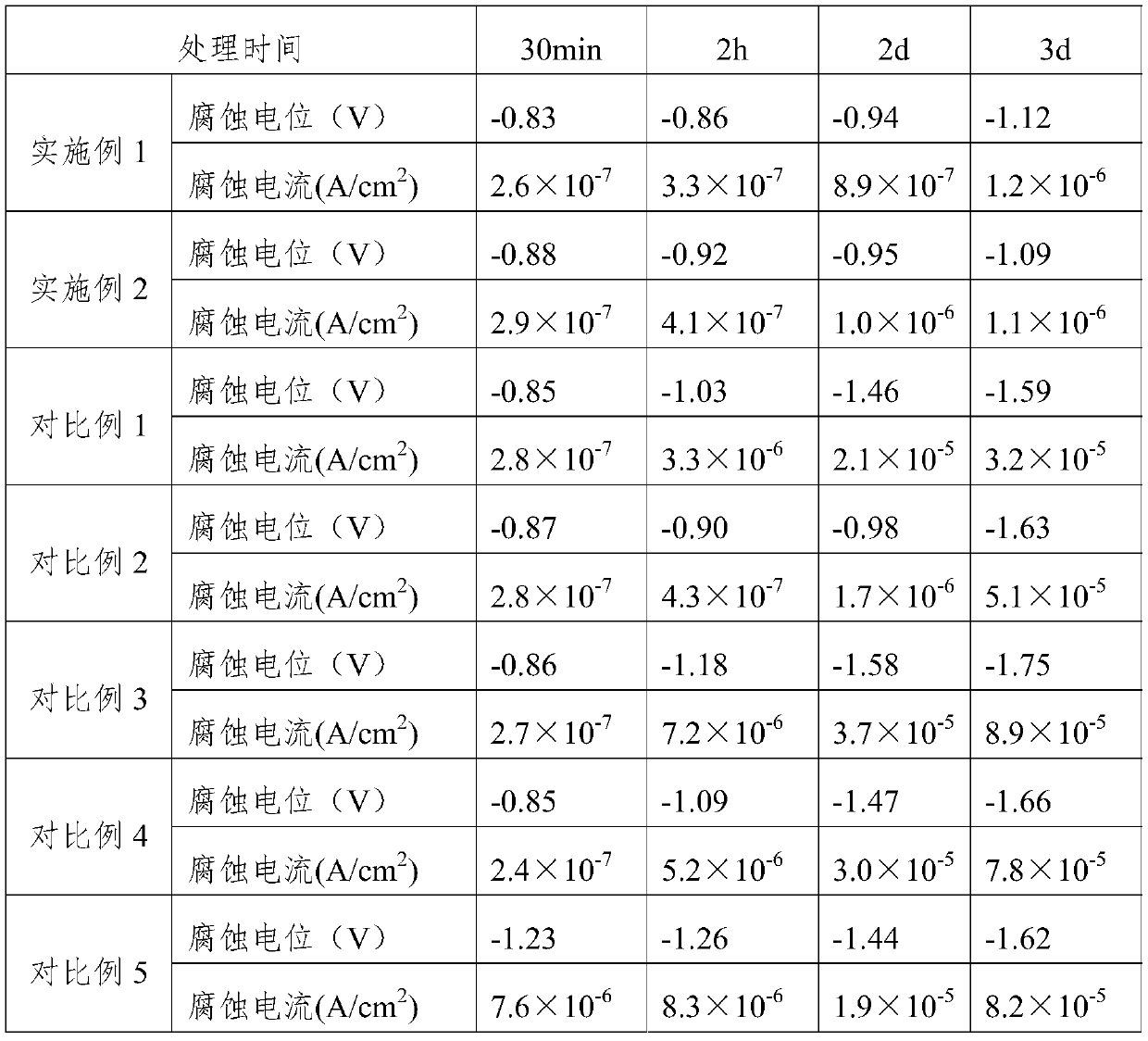

Examples

Embodiment 1

[0022] Preferred Embodiment 1 of the present invention provides a method for preparing a magnesium alloy anti-corrosion composite film, comprising the following steps:

[0023] Step 1, the magnesium alloy block is sequentially polished with 300 mesh, 800 mesh, and 1200 mesh sandpaper, and then put into deionized water and absolute ethanol in turn, and ultrasonic cleaning is performed respectively, and the ultrasonic cleaning time is 15 minutes;

[0024] Step 2: Spray a pretreatment liquid on the surface of the magnesium alloy block treated in step 1. The amount of pretreatment liquid sprayed is an average of 2.5 g per square centimeter of the surface of the magnesium alloy block. After spraying, leave it at room temperature for 12 minutes. The pretreatment solution is composed of the following components in weight percentage: 1.2% potassium phosphate, 3.5% sodium acetate, 1.5% sodium orthosilicate, and the rest is deionized water;

[0025] Step 3: Place the magnesium alloy blo...

Embodiment 2

[0031] Preferred embodiment 2 of the present invention provides a method for preparing a magnesium alloy anti-corrosion composite film, comprising the following steps:

[0032] Step 1, the magnesium alloy block is sequentially polished with 300-mesh, 800-mesh, and 1200-mesh sandpaper, and then put into deionized water and absolute ethanol in turn, and ultrasonic cleaning is performed respectively, and the ultrasonic cleaning time is 20 minutes;

[0033] Step 2: Spray a pretreatment liquid on the surface of the magnesium alloy block treated in step 1. The amount of the pretreatment liquid sprayed is 3g per square centimeter on the surface of the magnesium alloy block. After the spraying, let stand at room temperature for 15 minutes. The pretreatment solution is composed of the following components in weight percentage: 1.5% potassium phosphate, 4% sodium acetate, 1.8% sodium orthosilicate, and the rest is deionized water;

[0034] Step 3: Place the magnesium alloy block treated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com