A kind of water-based polyurethane topcoat with excellent recoating performance and preparation method thereof

A water-based polyurethane, performance technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of high price of silicone leveling agent, high price of polyurethane topcoat, affecting the adhesion between layers, etc., to improve leveling Sex and surface decoration, the effect of reducing the Bernard vortex phenomenon, avoiding the ills of orange peel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

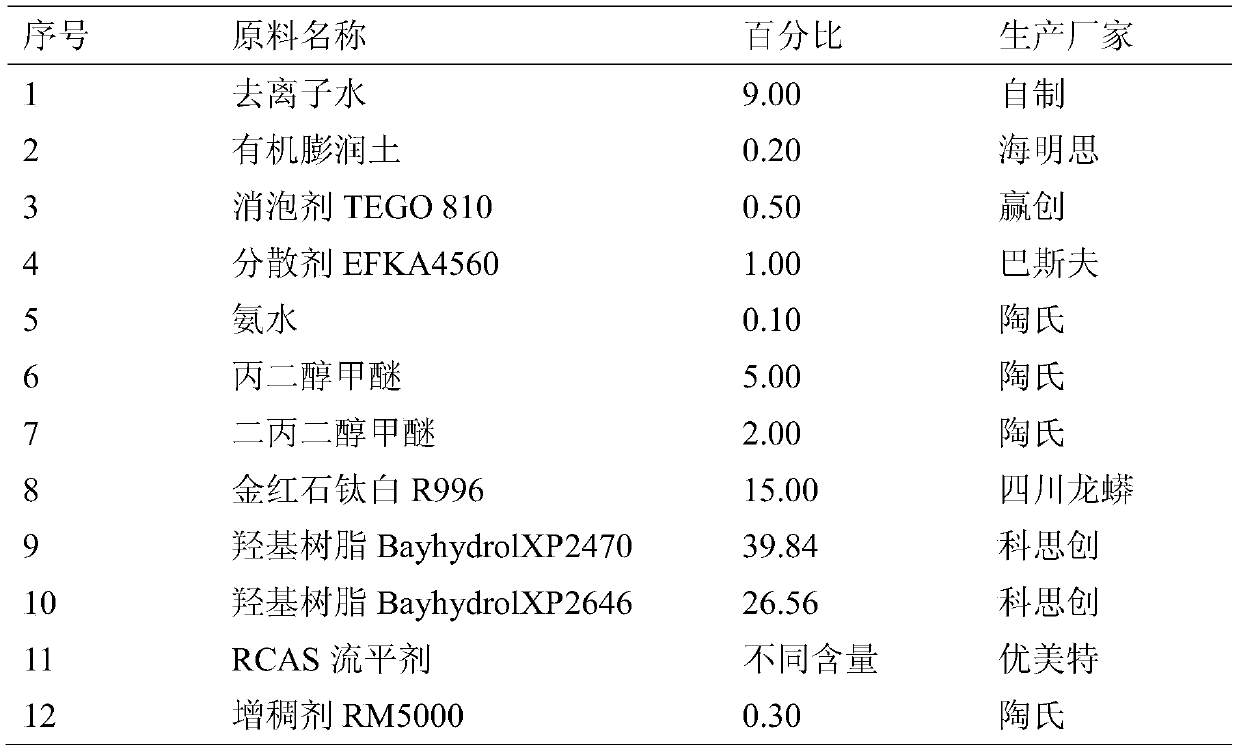

[0025] (1) According to the formula in Table 1, prepare the main ingredient through the following steps:

[0026] a. Add raw material 1, at a speed of 500r / min, add raw materials 2-7 in sequence, and stir for 5 minutes;

[0027] b. Increase the rotational speed to 800r / min, add raw material 8 into the solution of step (a), continue to stir for 20min until uniformly dispersed, and then grind until the fineness is ≤10μm;

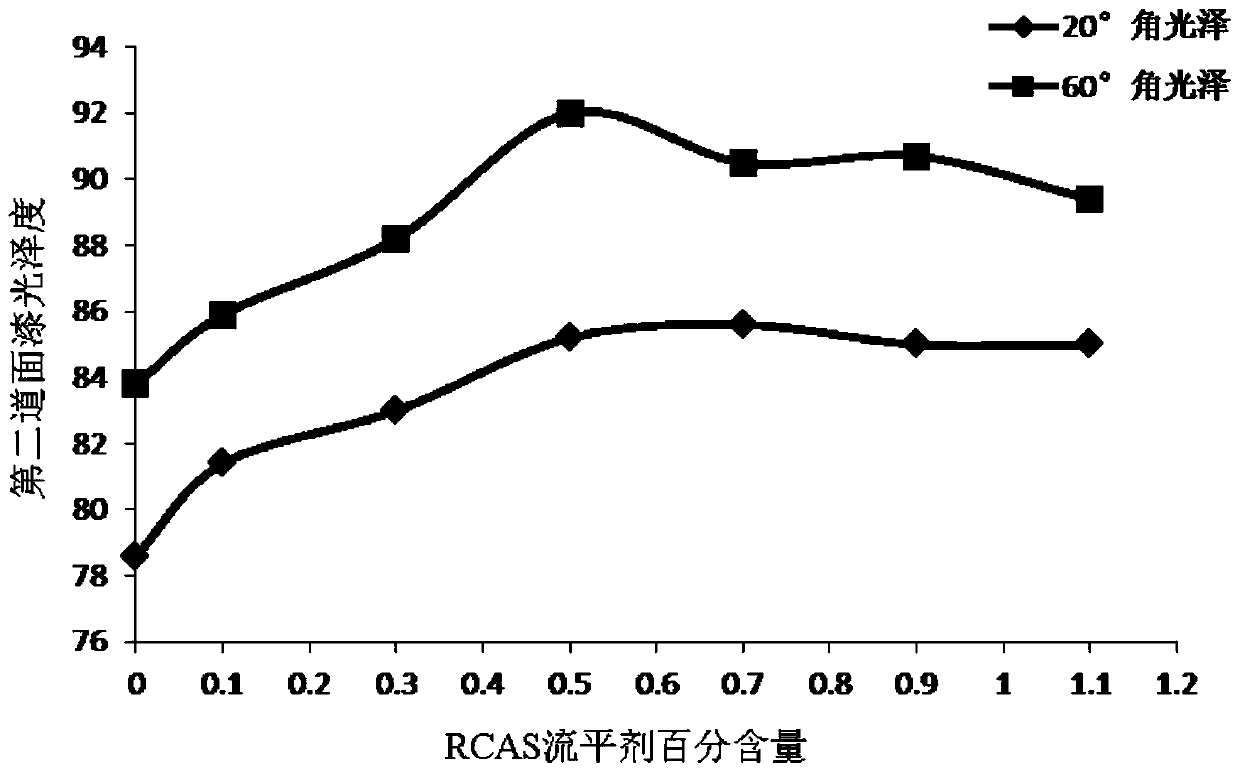

[0028] c. At 800r / min, add raw materials 9-12 in turn, stir for 20 minutes, filter, and use after standing for 24 hours; the percentage content of RCAS leveling agent is 0%, 0.1%, 0.3%, 0.5%, 0.7 %, 0.9%, 1.1%.

[0029] Table 1 Main agent formula of two-component water-based polyurethane topcoat

[0030]

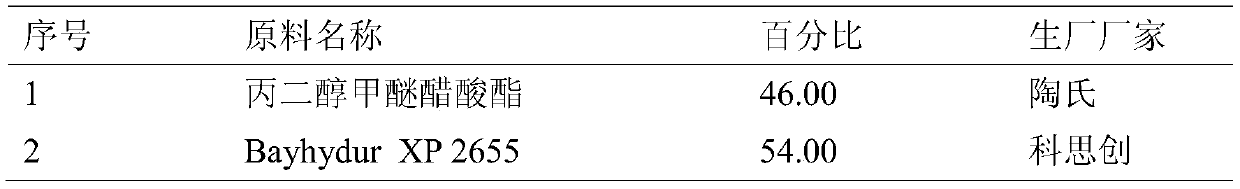

[0031] (2) According to the formula in Table 2, prepare a curing agent: at a speed of 800r / min, add raw materials 1 and 2 in Table 2, stir until uniformly dispersed, and obtain a curing agent.

[0032] Table 2 Two-component water-based polyurethane top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com