Glass spike and manufacture method thereof

A glass and road stud technology, which is applied in the field of glass road studs and its preparation, can solve problems such as poor adhesion, acid and alkali resistance, stained layer erosion and film removal, and affecting reflective functions, so as to avoid adhesion and corrosion resistance Poor performance, avoid environmental pollution, reduce waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

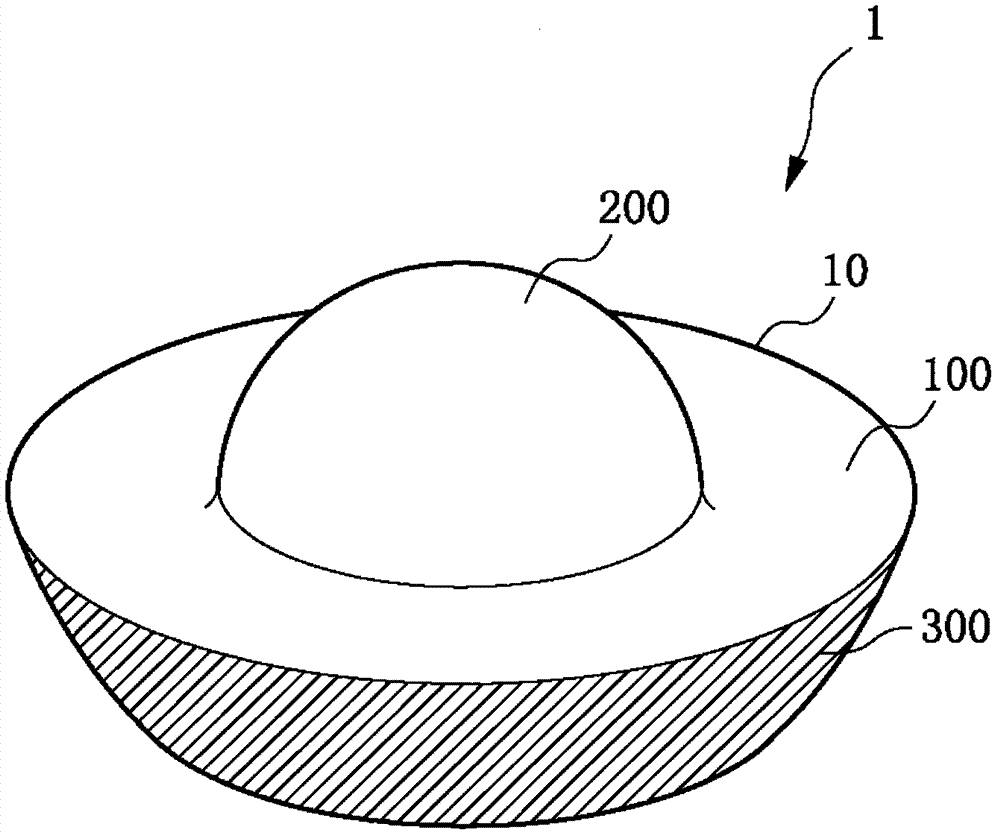

[0047] In addition, the present invention further provides a method for preparing a glass road stud, comprising steps: (A) melting a glass raw material to form a glass paste; (B) placing the glass paste in a molding mold to shape it into a road nail shape , wherein the molded glass road stud has a base and a protrusion, the base is connected to the protrusion, and the protrusion protrudes from the base; (C) slowly cooling the road stud; (D) coating the surface of the cooled glass road stud with a metal ion material layer (that is, a material layer containing chromogenic metal ions); (E) heating the glass coated with the metal ion material layer coating Block to a suitable first temperature above the softening temperature (about 550° C.), so that the metal ions of the metal ion material layer penetrate from the surface of the glass block into the subsurface layer and develop color; and (F) quenching (for example, quenching with wind cooling) Temper the glass block.

[0048] In...

Embodiment 1

[0075] The colorless glass melt paste is molded into a road stud-shaped glass block in a cat's-eye road stud mold, and then the formed glass block is slowly cooled to normal temperature in an annealing furnace.

[0076] Then, silver nitrate, iron oxide, and water are mixed thoroughly in a weight ratio of 1:50:50 to form a paste, and then the paste is applied to the entire surface of the glass block with a brush, and the glass block is reheated to an appropriate temperature above the softening point. The toughening temperature is maintained at 675°C for 8 minutes to allow silver ions to infiltrate from the surface of the glass block, and then it is taken out and quenched by air cooling to form a yellow cat-eye tempered glass road stud (yellow glass block). After cleaning, the aluminum metal reflective layer is coated on the bottom of the glass block by vacuum evaporation method to obtain a yellow cat's eye toughened glass road stud with yellow reflective effect, such as figure ...

Embodiment 2

[0079] The colorless glass melt paste is molded into a road stud-shaped glass block in a cat's-eye road stud mold, and then the formed glass block is slowly cooled to normal temperature in an annealing furnace.

[0080] Next, mix silver oxide, chromium oxide, and rosin oil in a weight ratio of 1.5:50:70 to form a paste, then spray the liquid on the entire surface of the glass block with a spray gun, and reheat the road stud to an appropriate temperature above the softening point. The tempering temperature is maintained at 685°C for 8 minutes to allow silver ions to penetrate into the glass block and turn yellow. Take it out and use wind cooling to quickly cool it into a yellow cat's-eye tempered glass road stud (yellow glass block). After cleaning the residue on the surface, the aluminum metal is plated on the bottom of the glass block by vacuum evaporation method to form a reflective layer, and the yellow cat's-eye toughened glass road stud with yellow reflective effect is obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com