Novel ultra-high-performance-concrete connector construction for expansion joint beam ends

An ultra-high-performance concrete technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as high precision requirements for joint structures, difficulty in achieving expected construction effects, and difficulty in ensuring long-term effects, etc., to reduce local fractures Impaired performance, simplified construction process, and increased effective service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

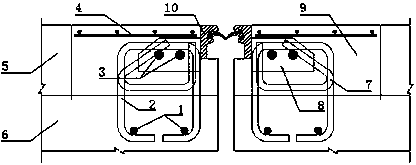

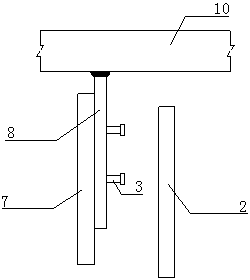

[0031] Referring to the accompanying drawings: This embodiment is a new type of ultra-high performance concrete joint structure used for expansion joint beam ends. Taking bridge construction as an example, it includes the ultra-high performance concrete joint body 9 and the connecting joint body 9 arranged at the ends of two adjacent construction beams. The connecting piece of the two joint bodies 9 , the joint body 9 includes anchor tendons 7 , anchor plates 8 and shear connection pegs 3 . During the construction process, reserved slots for expansion joints are reserved between two adjacent beam ends, and the pre-embedded steel bars 2 are partially pre-embedded at the ends of the beam body 6 during the construction process of the beam body 6, and extend upwards to the reserved slots for the expansion joints. Groove, pre-embedded steel bars 2 in the bottom beam body 6 synchronously pre-embedded two crossing steel bars 1 arranged in parallel. The welding work between the anchor...

Embodiment 2

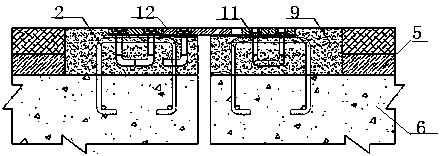

[0034] Referring to the accompanying drawings, this embodiment is a new type of ultra-high performance concrete structure for beam ends of expansion joints, including an ultra-high performance concrete joint body 9 arranged at the ends of two adjacent construction beams and a connecting piece connecting the two joint bodies 9 The joint body 9 includes pre-embedded screws 11, the bottom ends of the pre-embedded screws 11 are bent, some of the bent parts at the bottom ends of the screws 11 face each other, and the bent front ends are in contact with each other. During the construction process, reserved grooves for expansion joints are reserved at the ends of adjacent beams, and the pre-embedded steel bars 2 are partially pre-embedded at the ends of the beam body 6 during the construction process of the beam body 6, and extend upwards to the reserved grooves for expansion joints. Two crossing reinforcing bars 1 arranged in parallel are pre-embedded synchronously in the bottom beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com