Crank-arm steel dam gate

A technology of steel dams and curved arms, which is applied in the dam structure field of water conservancy facilities, can solve the problems of affecting the service life of lifting cylinders, soaking in water, etc., and achieve the effect of increasing the cross-flow section of the river channel, reducing the force and reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

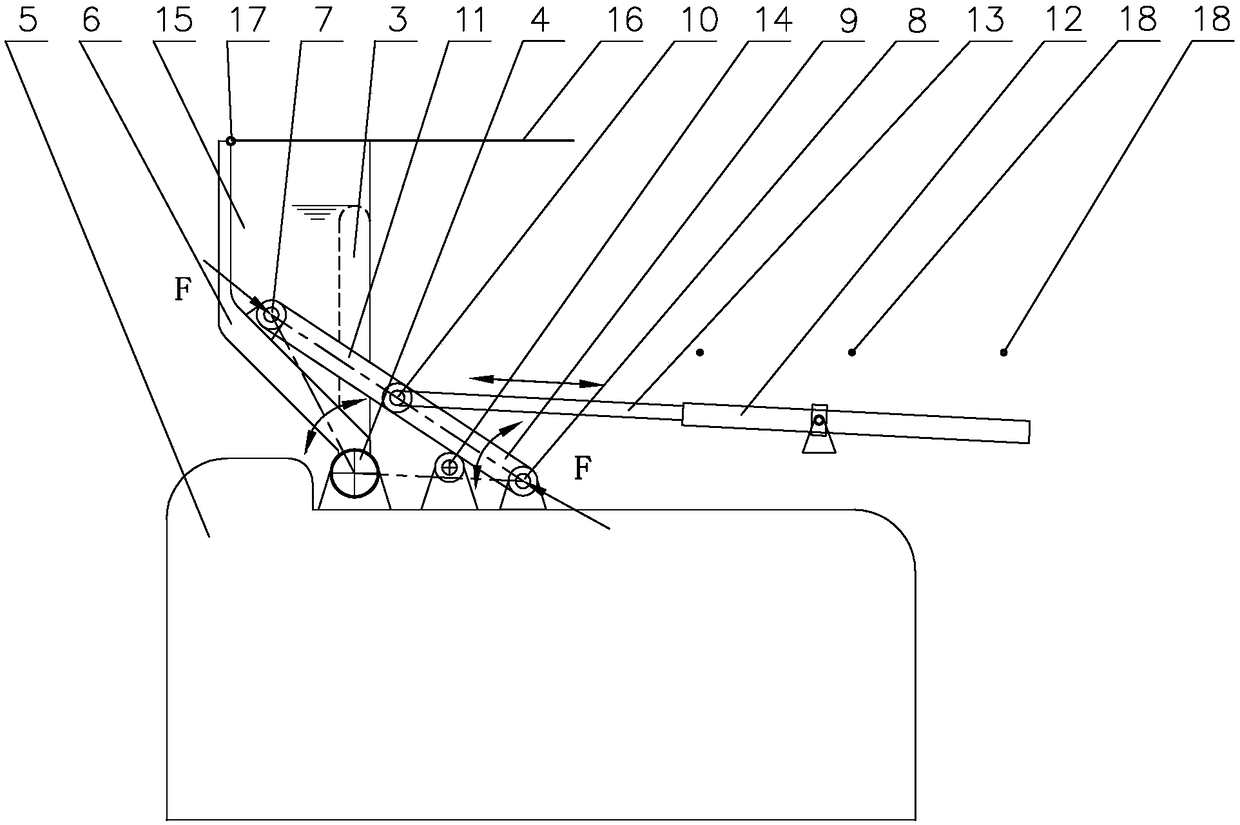

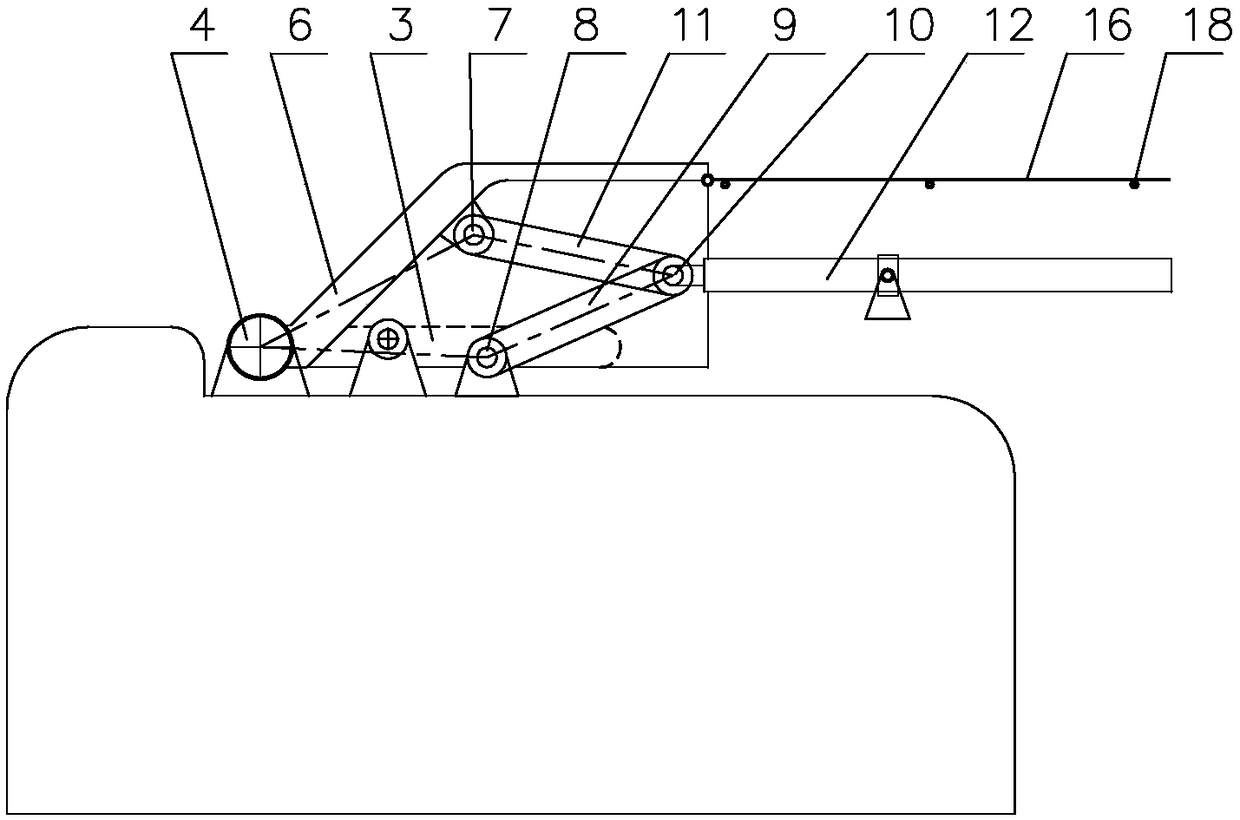

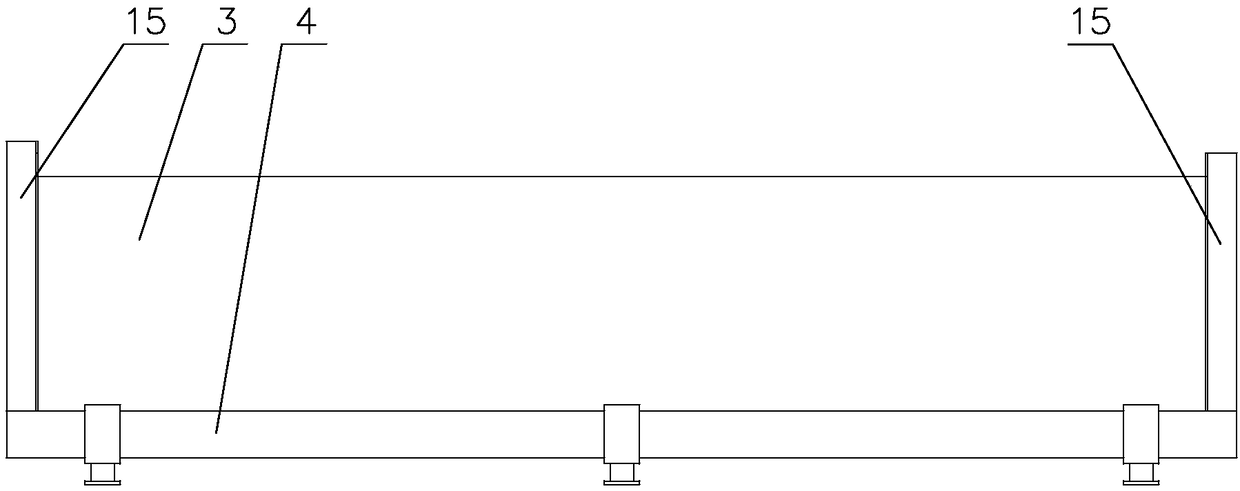

[0030] Figure 1 to Figure 5 It is a structural schematic diagram of a crank arm steel dam gate. As can be seen from the figure, it includes a steel dam door leaf 3 installed between the two left side walls 1 and right side wall 2, and the bottom of the steel dam door leaf 3 is connected with the dam body 5 through the bottom transverse shaft 4, and the steel dam The door leaf 3 swings around the bottom transverse axis 4 . When the steel dam door leaf 3 is swung up, the water can be blocked like figure 1 As shown, the hem achieves water release as figure 2 shown. The two ends of the steel dam door leaf 3 on the water-facing surface and the bottom transverse shaft 4 are welded with forward-extending curved arms 6 respectively, or the two ends of the steel dam door leaf 3 on the upstream-facing surface are respectively welded with forward-ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com