Unloading platform for building construction

A technology of unloading platform and building construction, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of time-consuming and laborious installation and dismantling, and no safety accidents of weighing modules, so as to prevent overload use and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

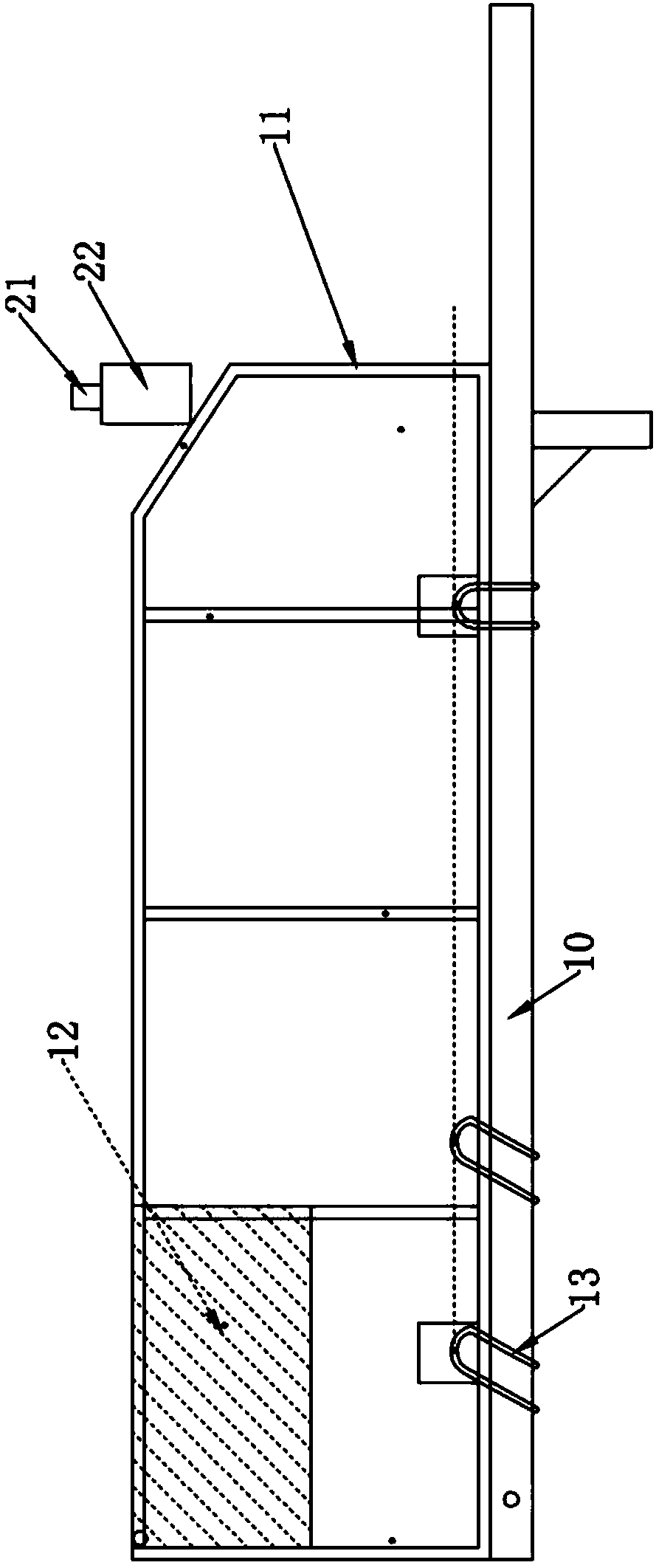

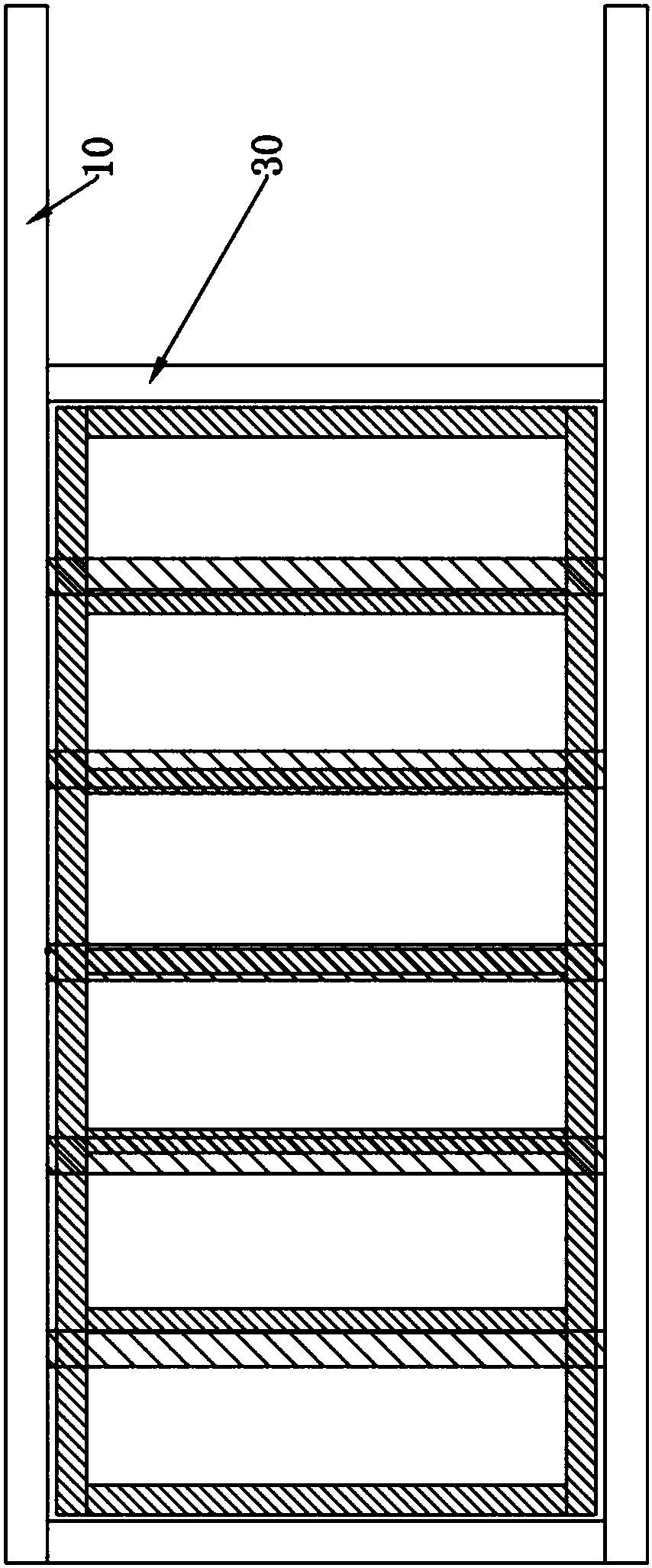

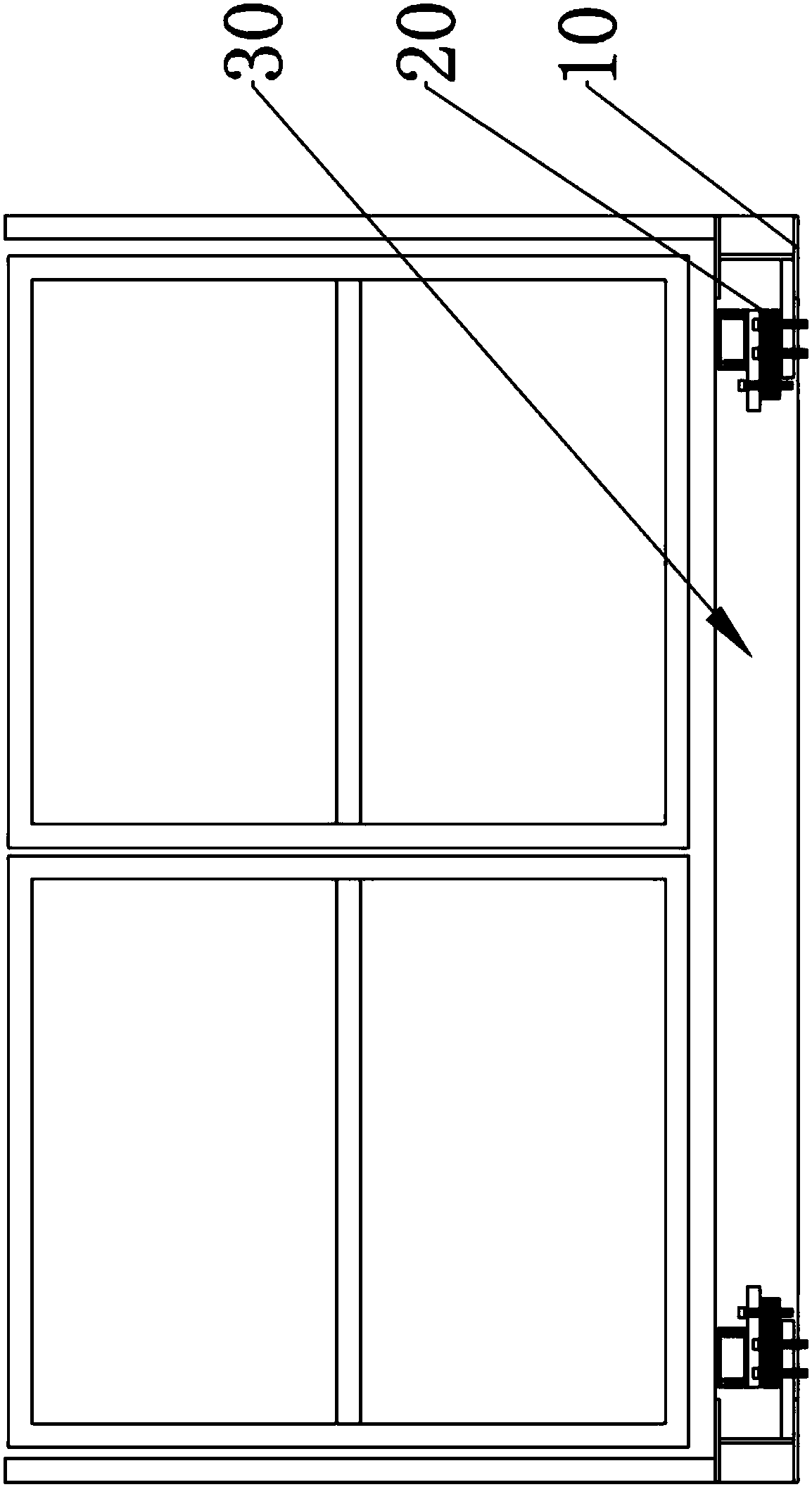

[0022] Basic as attached Figure 1-3 Shown: an unloading platform for building construction, including main beams 10 and cross beams 30, multiple sets of cross beams 30 are connected between two groups of relatively parallel main beams 10, and it is characterized in that: main beams 10 and cross beams 30 are fixed to form Bottom frame, the bottom frame is attached with the side closure plate 12 that is arranged along its circumference and the bottom closure plate that is positioned at the top surface of the bottom frame, and the side of the building that side direction closure plate 12 faces is also provided with door body, bottom frame four Weighing modules 20 are provided at each of the top corners; in this way, the monitoring of weighing modules 20 is more sensitive and the force is more balanced.

[0023] Compared with the prior art, the present invention has the advantages of:

[0024] The invention easily realizes toolization, finalization and standardization of the unl...

Embodiment 2

[0028] The only difference from Embodiment 1 is that the lateral sealing plate 12 includes a corrugated board layer and a flat board layer welded to the corrugated board layer, and several cavities are formed between the corrugated board layer and the flat board layer, and the cavities are vertically arranged and Both ends are connected, and the lower end of the cavity is equipped with a sealing iron ring and a sealing plug that slides with the sealing iron ring. The sealing plug is made of a magnet. Usually, the sealing plug and the sealing iron ring are attracted to seal the lower end of the corrugated board layer. The cavity is filled with aluminum sulfate solution, and part of the cavity is filled with sodium hydroxide solution; when the construction site encounters a fire, the flat layer, sealing iron ring, sealing plug and corrugated board layer are easy to absorb heat and heat up, and the sealing plug quickly reaches Curie temperature, the magnetism disappears and falls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com