An angular contact thrust ceramic-ball bearing

A ceramic ball and thrust angle technology, applied in the direction of ball bearings, bearing components, shafts and bearings, etc., can solve the problems of limited bearing capacity, bearing failure, unsuitable for high-speed rotation, etc., achieve strong bearing capacity, improve bearing capacity, save The effect of free space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

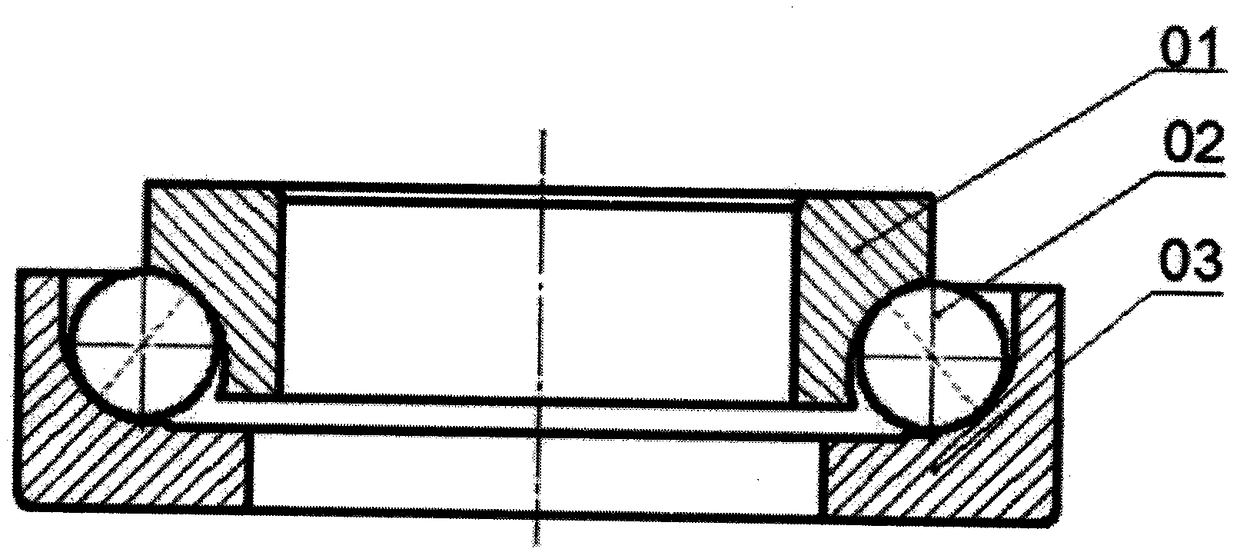

[0016] like figure 1 As shown, a cageless thrust angular contact ceramic ball bearing includes an outer ring 01, ceramic balls 02, and an inner ring 03, and the ceramic balls are evenly distributed between the raceways of the outer ring 01 and the inner ring 03.

[0017] The bearing adopts a full-ball design method, which saves a part of free space in the raceway of the inner and outer rings, which is used to fill more ceramic balls, and improves the bearing capacity of the bearing.

[0018] Ceramic ball 02 has small thermal expansion coefficient and friction coefficient, and has the characteristics of high temperature resistance and high speed. The ceramic ball 02 has self-lubricating properties, and it can still operate normally in a short-term oil shortage. The outer ring 01 and the inner ring 03 are carburized on the surface, which impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com