Vibration isolator

A vibration isolator and vibration isolation technology, applied in the directions of supporting machines, non-rotating vibration suppression, engine frames, etc., can solve the problem of reducing the installation rigidity of vibration isolators, and achieve the effect of reducing vibration energy and avoiding the reduction of installation rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

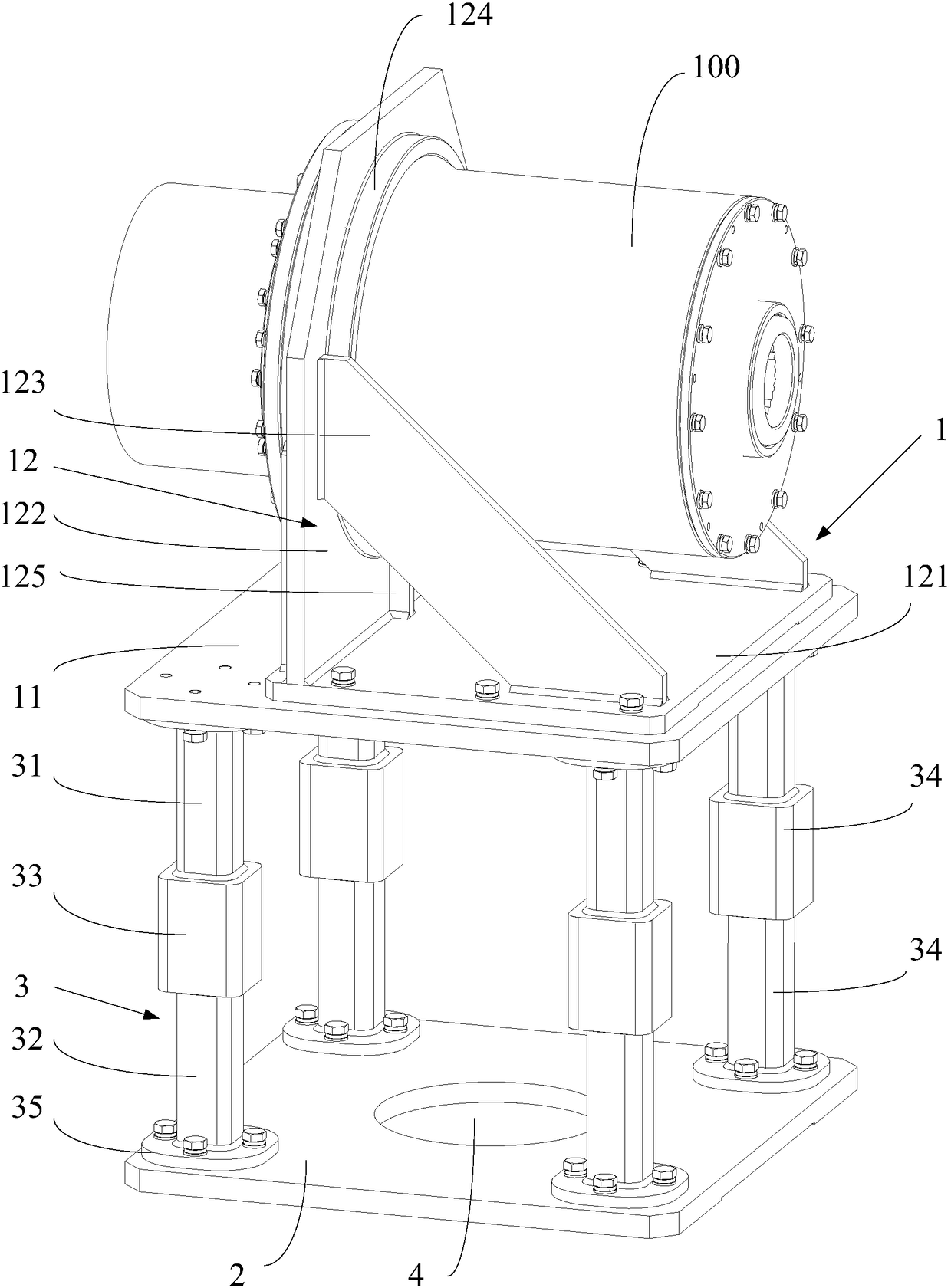

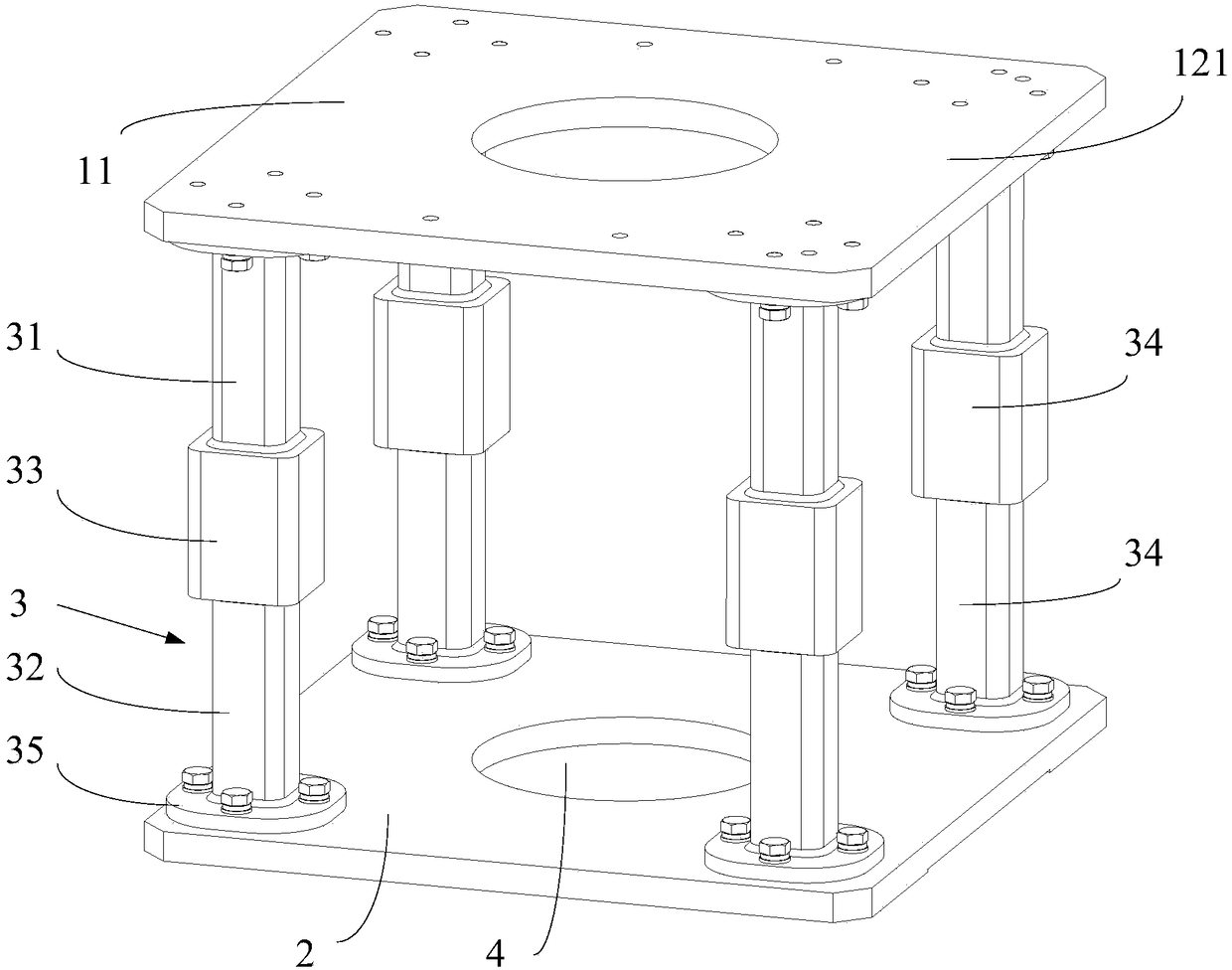

[0022] An embodiment of the present invention provides a vibration isolator, figure 1 is a schematic diagram of the structure of the vibration isolator, such as figure 1 As shown, the vibration isolator includes: a mounting part 1, a base 2 and a plurality of vibration isolating parts 3, each vibration isolating part 3 is respectively spaced and fixed between the mounting part 1 and the base 2, the mounting part 1, the base 2 And all vibration isolation parts 3 are rigid structural members, each vibration isolation part 3 all comprises the first support column 31, the second support column 32 and mass block 33, for any vibration isolation part 3, the first support column 31 and The quality of the second support column 32 is all less t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap