Refrigeration system with combination of adsorption and steam compression and control method thereof

A vapor compression and refrigeration system technology, applied in the direction of refrigerators, compressors, refrigeration components, etc., can solve the problems that cannot be controlled independently, cannot cooperate well with each other, and limit the application range of adsorption refrigeration, so as to solve the problem of insufficient condensation heat , The effect of reducing power supply pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

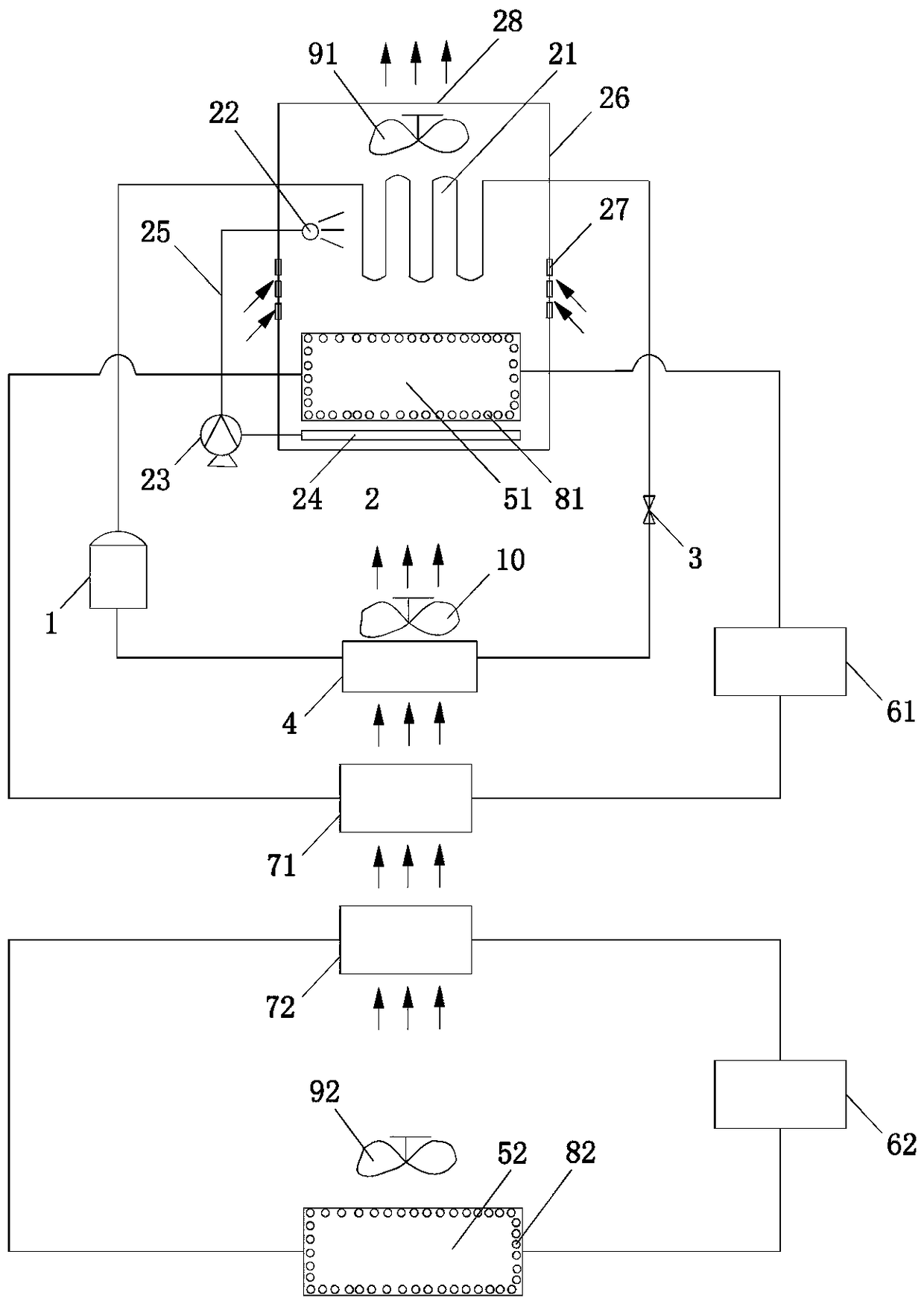

[0053] like figure 1 As shown, a refrigeration system combining adsorption and vapor compression includes a compressor 1, an evaporative cooler 2, a throttle valve 3, and an evaporator 4 that are sequentially connected to form a vapor compression refrigeration cycle, and also include sequentially connected to form a first adsorption cycle. The first adsorption bed 51, the first adsorption condenser 6161, and the first adsorption evaporator 71, the condensation heat released by the evaporative cooler 2 provides heat for the first adsorption bed 51.

[0054] The first refrigerant circulates in the vapor compression refrigeration cycle connected by the compressor 1, the evaporative cooler 2, the throttle valve 3 and the evaporator 4, and the second refrigerant circulates in the first adsorption bed 51 and the first adsorption condenser 6161. Circulate in the first adsorption cycle formed by the connection of the first adsorption evaporator 71.

[0055] During the day, when the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com