Indoor 3D data automatic collection equipment

A technology for automatic collection and 3D data, applied in the field of 3D measurement, it can solve problems such as heavy workload, slow overall collection speed, and inability to splicing data sets together, achieving the effect of fast collection speed and easy processing in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

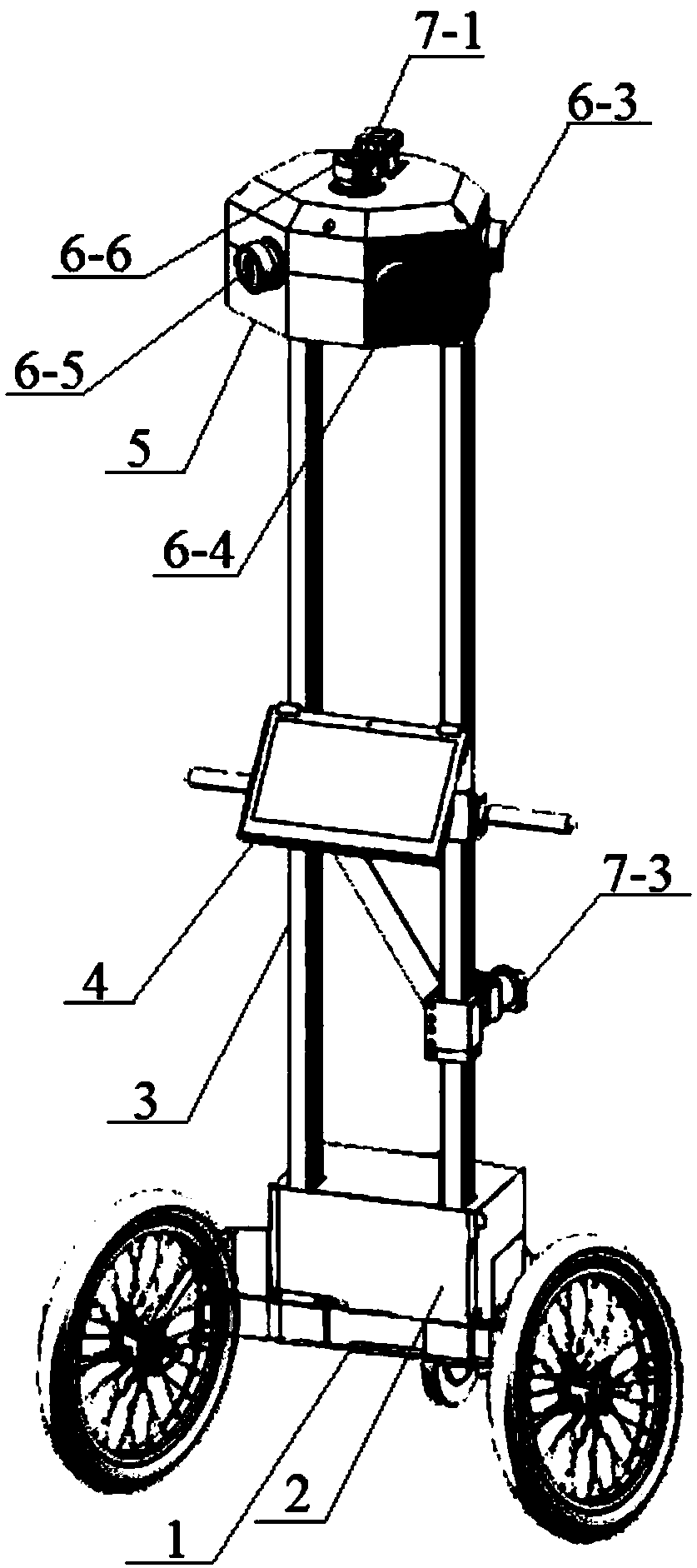

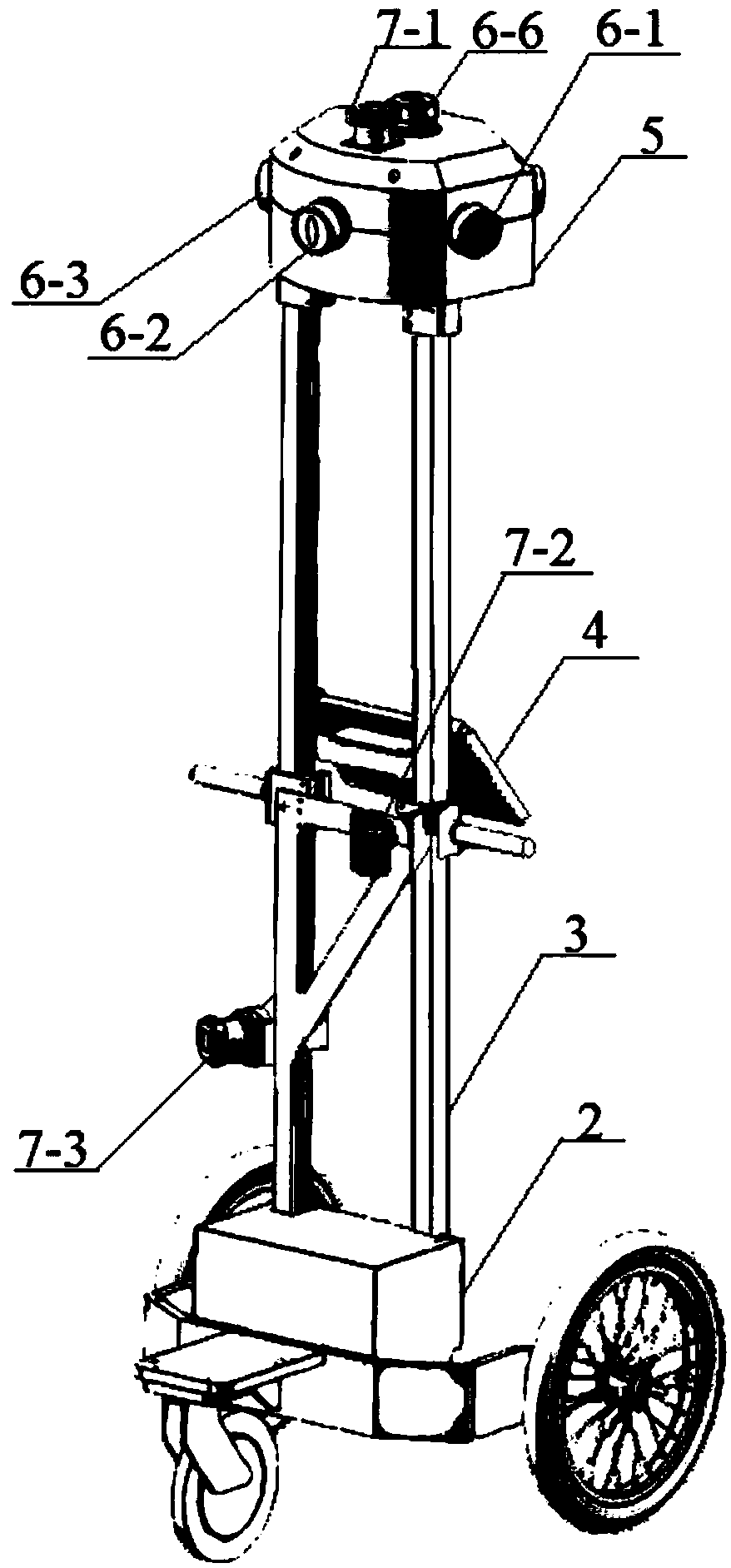

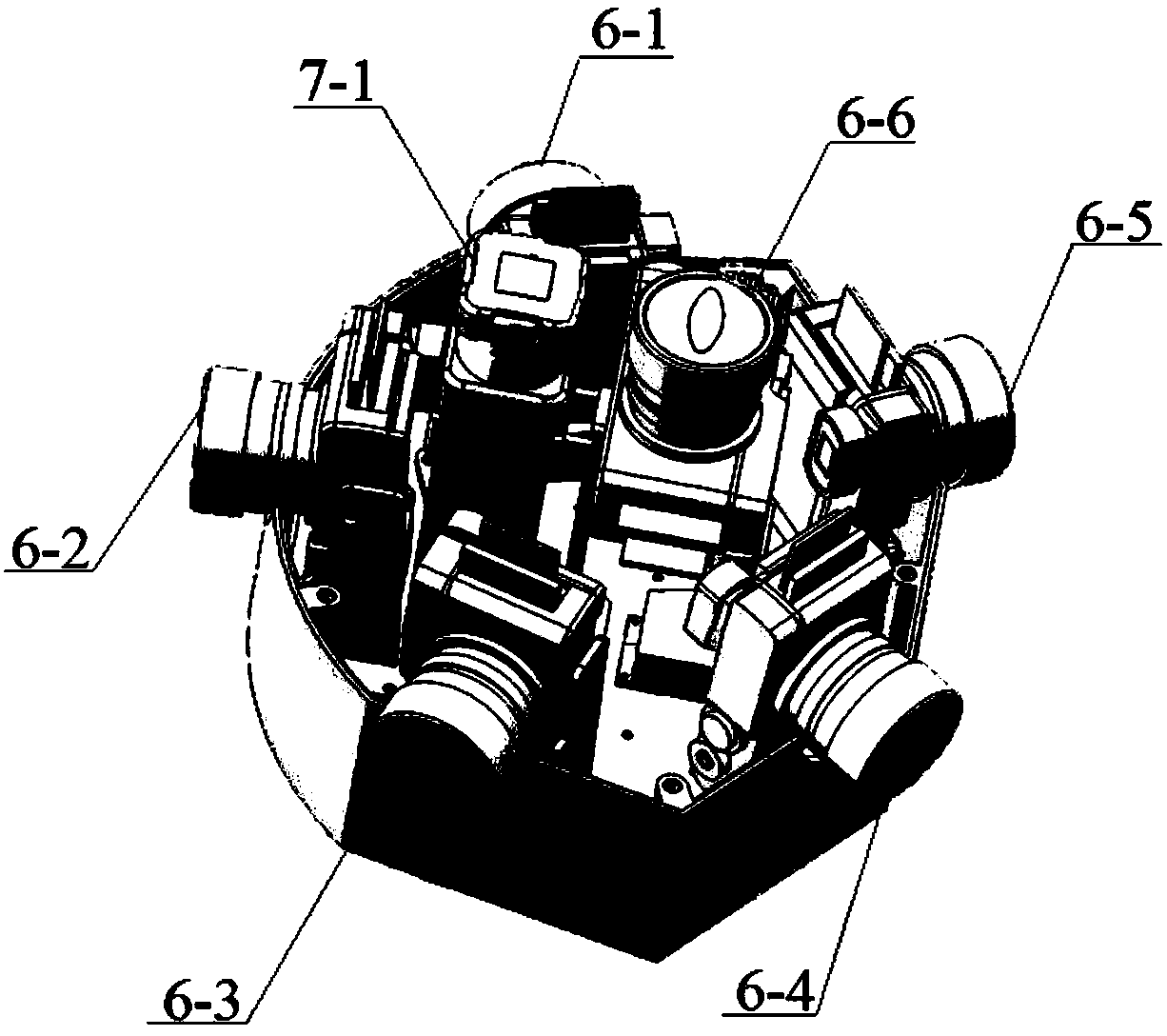

[0038] Example 1, such as Figure 1-2 As shown, an indoor three-dimensional data automatic acquisition device according to an embodiment of the present invention includes: a chassis 1, a host and a power supply compartment 2, a bracket 3, a monitor 4, a head 5, a camera component, a laser radar component and an inertial measurement unit.

[0039] Chassis 1 is a walking mechanism, which provides walking and moving functions for the entire collection equipment. Chassis 1 can be as Figure 1-2 Shown is a wheeled running gear made up of three wheels. This three-wheeled walking mechanism has stability, one front wheel and two rear wheels, the front wheel is used as a steering rudder to change the direction, and the rear wheel is used for driving, which can realize long-distance movement. Chassis 1 also can adopt crawler type running mechanism. The crawler-type traveling mechanism can cross obstacles without self-positioning wheels and steering mechanisms. When turning, it is eno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com