A temperature field measuring device and method for rolling bearing test

A technology of rolling bearing and measuring device, which can be used in temperature measurement of moving solids, mechanical bearing testing, etc., and can solve problems such as measurement problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

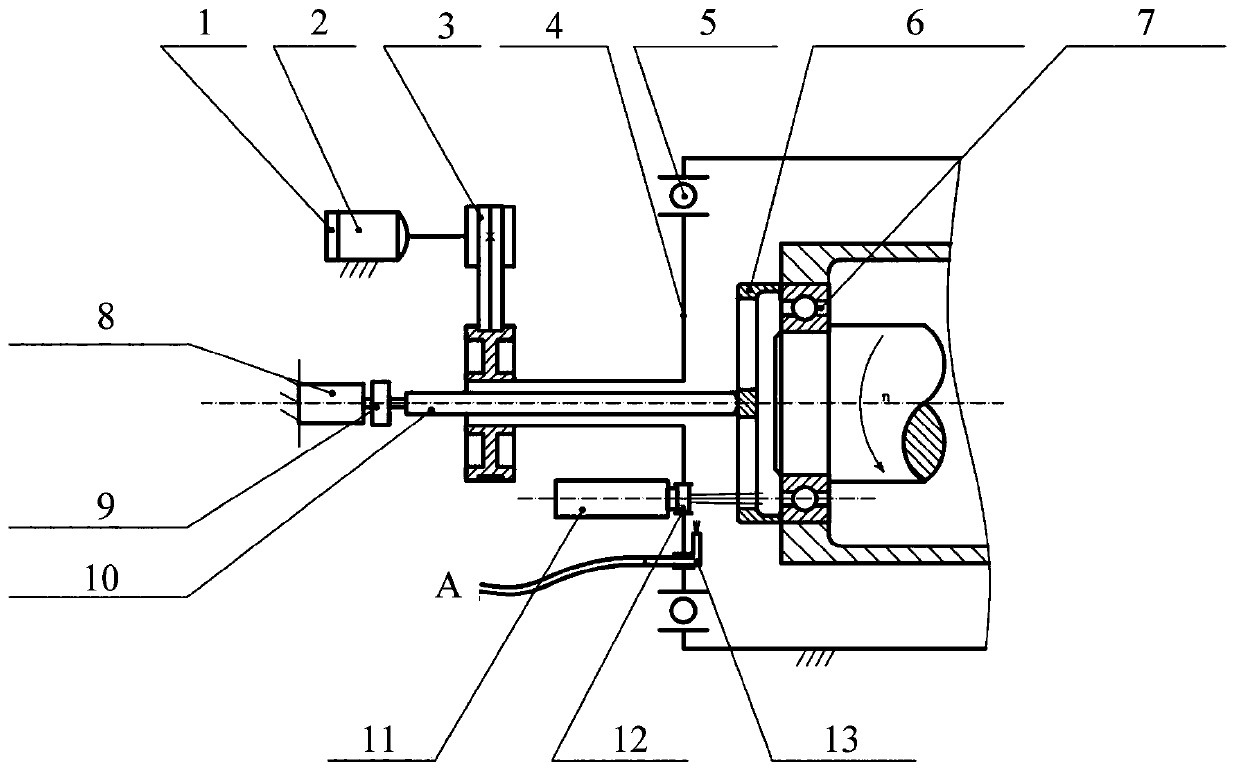

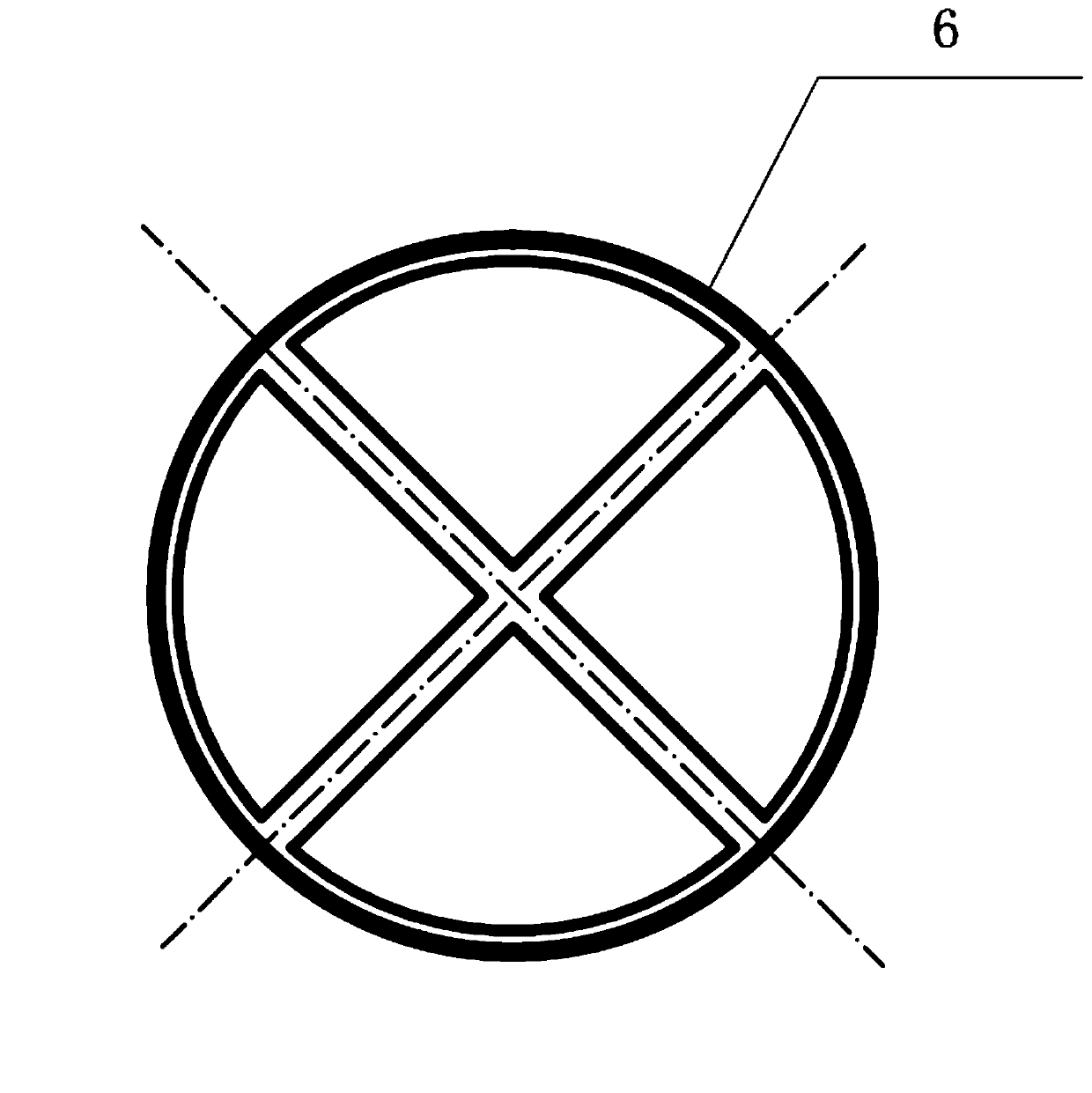

[0029] Embodiment one: if figure 1 As shown, a temperature field measuring device for a rolling bearing test involved in this embodiment includes a measuring part, a transmission part and an optical path cleaning part,

[0030] The measurement section includes a thermal imager,

[0031] The transmission part includes servo motor, force sensor, loading rod, code disc, motor, belt drive, support bearing, axial loading disc, test bearing, end cover,

[0032] The optical path cleaning part includes germanium glass and purge module,

[0033] Open a hole on the end cover of the outer box to install the thermal imager, the head of the thermal imager extends into the hole, and the rest of the thermal imager is supported by the bracket on the end cover;

[0034] The main shaft of the servo motor is connected to the end cover through the transmission pulley, the motor is connected to the end cover through the belt drive, and the code disc is connected to the motor; there is a hole in ...

Embodiment 2

[0038] Embodiment two: if figure 1 As shown, a temperature field measuring device for a rolling bearing test involved in this embodiment, and a temperature field measuring device for a rolling bearing test of the present invention, the end of the loading rod is a spherical surface.

Embodiment 3

[0039] Embodiment three: as figure 1 As shown, the temperature field measuring device for rolling bearing test involved in this embodiment, in the temperature field measuring device for rolling bearing test in this embodiment, the rotation range of the end cover is -180°~+180°.

[0040] The thermal imager used for temperature measurement is installed on the end cover. When the temperature measurement object is the inner ring or rolling body of a high-speed rotating bearing, the thermal imager remains still, and the thermal imager can scan a period of time for each rotation of the bearing. surface temperature. When the measurement object is the bearing outer ring that remains stationary, the thermal imager can be driven by the end cover to rotate slowly. The tail of the thermal imager is connected to the host computer by cable to avoid the winding of the cable and the rotating mechanism, so the rotation range of the end cover where the thermal imager is installed is -180°~+180...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com