Method for preparing and testing rubber aggregate admixed foam concrete

A technology of foam concrete and rubber aggregates, which is applied in the fields of civil engineering and building materials, can solve problems such as unsatisfactory effects and reduce shrinkage, and achieve obvious effects and reduce the crack width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

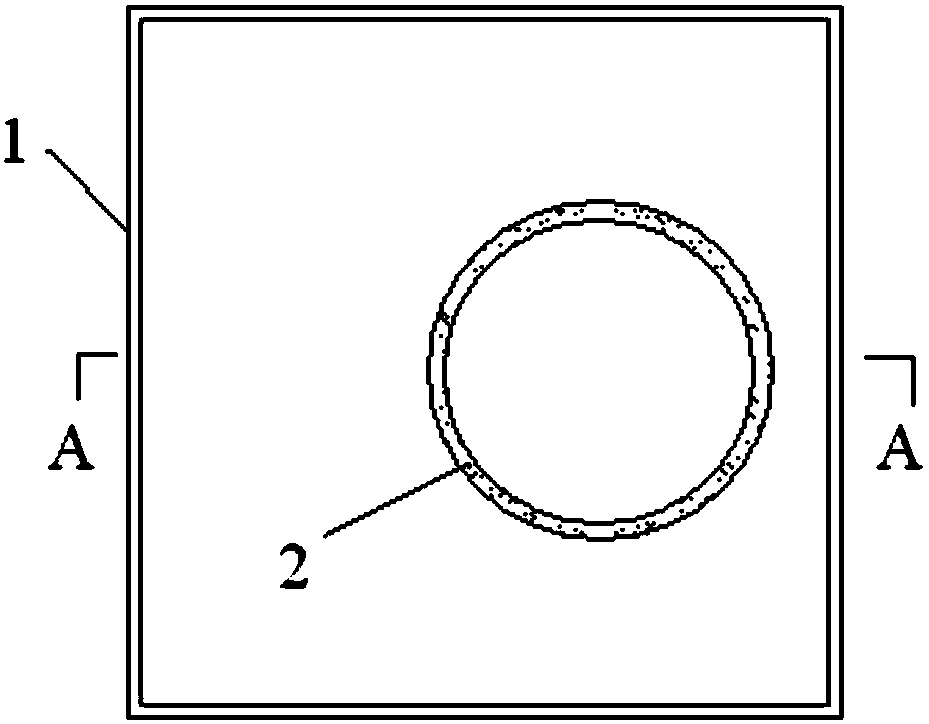

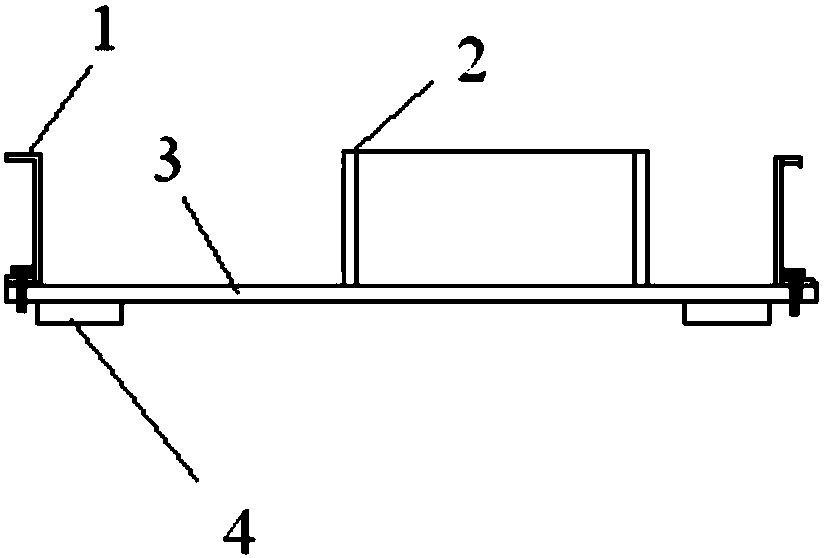

[0019] Below in conjunction with accompanying drawing, the present invention is further described, and the present invention protects a kind of foamed concrete preparation and testing method that adds rubber aggregate, specifically as follows:

[0020] (1) Select the dry density, strength, thermal conductivity, and workability of the foamed concrete mixed with rubber aggregates as the design parameters of the foamed concrete.

[0021] (2) Determine the water-cement ratio of foam concrete according to "Technical Regulations for the Application of Foam Concrete" (JGJ / T 341-2014) and "Standards of the Construction Industry of the People's Republic of China" (JG / T 266-2011). The water-cement ratio is generally between 0.45 and 0.60, which is more suitable.

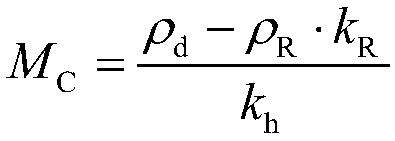

[0022] (3) According to the selected design dry density, water-cement ratio and other parameters, determine the mix ratio of foam concrete, and the relevant formulas involved are as follows:

[0023] ①Amount of cement in foam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com