Wear-resistant and corrosion-resistant carbide ceramic coating and preparation method thereof

A ceramic coating and carbide technology, applied in the field of wear-resistant and corrosion-resistant carbide ceramic coating and its preparation, can solve the complex preparation method of SiC coating, poor bonding between coating and substrate, and large shrinkage of SiC coating and other problems, to achieve the effect of low size range requirements, increased compactness and good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention discloses a preparation method of a wear-resistant and anti-corrosion carbide ceramic coating, which specifically comprises the following steps.

[0036] Step 1: Pretreatment of the substrate

[0037] Sand the surface of the substrate first to remove the oxide skin, and then use finer sandpaper to polish it until the surface of the substrate is flat and the roughness is consistent. Put the polished substrate in anhydrous ethanol for 10-15 minutes to sonicate to remove the remaining abrasive grains and other pollution stains on the surface of the substrate. Put the ultrasonic substrate in an oven at 60°C to dry for 10-30 minutes, so as to completely volatilize the absolute ethanol on the surface of the substrate and ensure that the surface of the substrate is clean and pollution-free; complete the pretreatment of the substrate according to the above requirements to obtain a clean substrate.

[0038] Step 2: Preparation of impregnation solution and impregna...

Embodiment 1

[0058] A method for preparing a wear-resistant and anti-corrosion carbide ceramic coating, specifically comprising the following steps:

[0059] Step 1: Pretreatment of the substrate

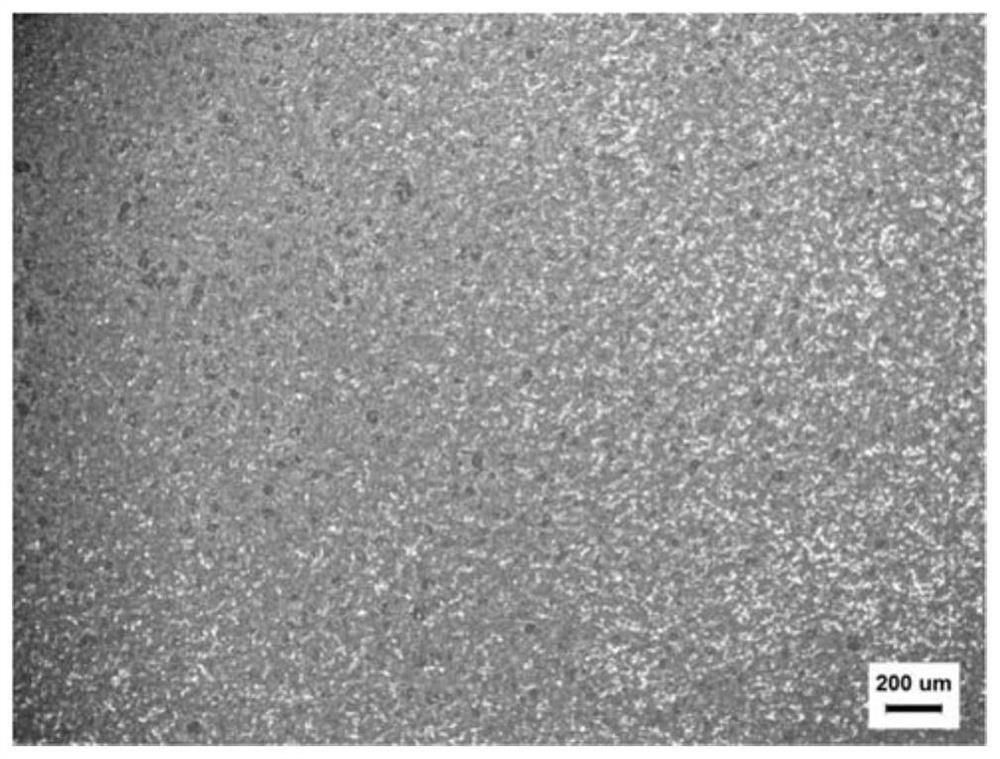

[0060] The Q235 steel was first polished off the scale on the surface with No.320 sandpaper, and then polished successively with No.600 and No.800 sandpaper until the surface of the metal substrate was flat and the roughness was consistent. Put the polished metal substrate in anhydrous ethanol for 10 minutes and ultrasonically remove the remaining abrasive grains and other pollution stains on the surface of the metal substrate. Put the ultrasonic metal substrate in an oven at 60°C for 15 minutes to dry the anhydrous ethanol on the surface of the metal substrate and ensure that the metal surface is clean and free from contamination. Complete the pretreatment of the substrate according to the above requirements to obtain a clean substrate.

[0061] Step 2: Preparation of impregnation solution and...

Embodiment 2

[0067] A method for preparing a wear-resistant and anti-corrosion carbide ceramic coating, specifically comprising the following steps:

[0068] Step 1: Pretreatment of Metal Substrate

[0069] The Q235 steel was first polished off the scale on the surface with No.320 sandpaper, and then polished successively with No.600 and No.800 sandpaper until the surface of the metal substrate was flat and the roughness was consistent. Put the polished metal substrate in anhydrous ethanol for 15 minutes and ultrasonically remove the remaining abrasive grains and other pollution stains on the surface of the metal substrate. Put the ultrasonic metal substrate in an oven at 60°C for 30 minutes to dry the anhydrous ethanol on the surface of the metal substrate and ensure that the metal surface is clean and free from contamination. Complete the pretreatment of the substrate according to the above requirements to obtain a clean substrate.

[0070] Step 2: Preparation of impregnation solution a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com