Metakaolin-based geopolymer for oil-gas reservoir well cementation and swelling agent thereof

A metakaolin and polymer technology, which is applied in the field of metakaolin-based geopolymers and expansion agents for oil and gas reservoir cementing, can solve problems such as large shrinkage of hardened bodies, and achieve high efficiency utilization, environmental protection, and cementing quality Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Raw material weight ratio is:

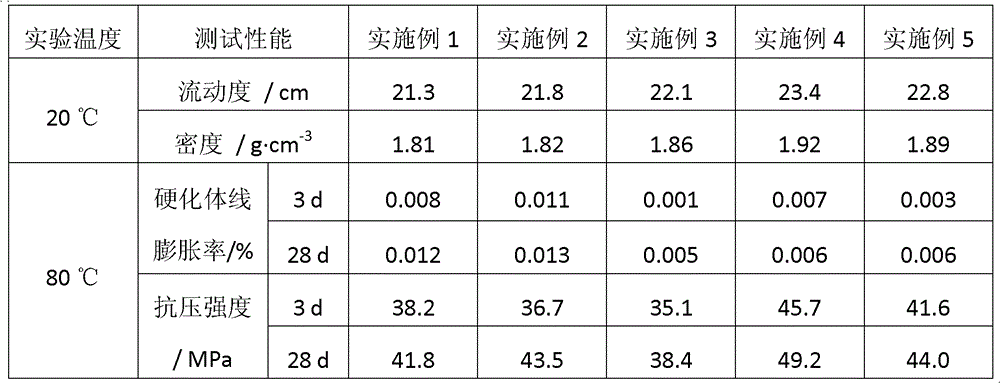

[0026] Metakaolin 900g (500 mesh), slag powder (Jiangnan Grinding Co., Ltd., 200 mesh) 100g, expansion agent 60g, wherein in the expansion agent 30 parts of calcium oxide and 70 parts of calcium aluminate, the prepared metakaolin-based geopolymer was Its performance can be seen in Table 1.

Embodiment 2

[0028] Raw material weight ratio is:

[0029] Metakaolin 700g (80 mesh), fly ash (Nanjing Yangzi Thermal Power Company, 500 mesh) 300g, expansion agent 40g, wherein in the expansion agent 60 parts of magnesium oxide, 40 parts of sodium aluminate, the prepared metakaolin-based geopolymer was Its performance can be seen in Table 1.

Embodiment 3

[0031] Raw material weight ratio is:

[0032] Metakaolin 600g (400 mesh), phosphorus slag powder (Sichuan Longli Phosphorus Industry Co., Ltd., 80 mesh) 400g, expansion agent 40g, including 20 parts of magnesium chloride and 80 parts of aluminum potassium sulfate in the expansion agent, prepared metakaolin based geological polymerization The properties of the tested materials are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com