Printing task scheduling method, device and system

A technology for printing tasks and scheduling methods, applied in the field of 3D printing, can solve the problems of unbalanced supply and demand matching of 3D printing services and tasks, lack of efficient availability, and low utilization of 3D printing equipment resources, so as to improve resource utilization and improve satisfaction. degree, the effect of increasing depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

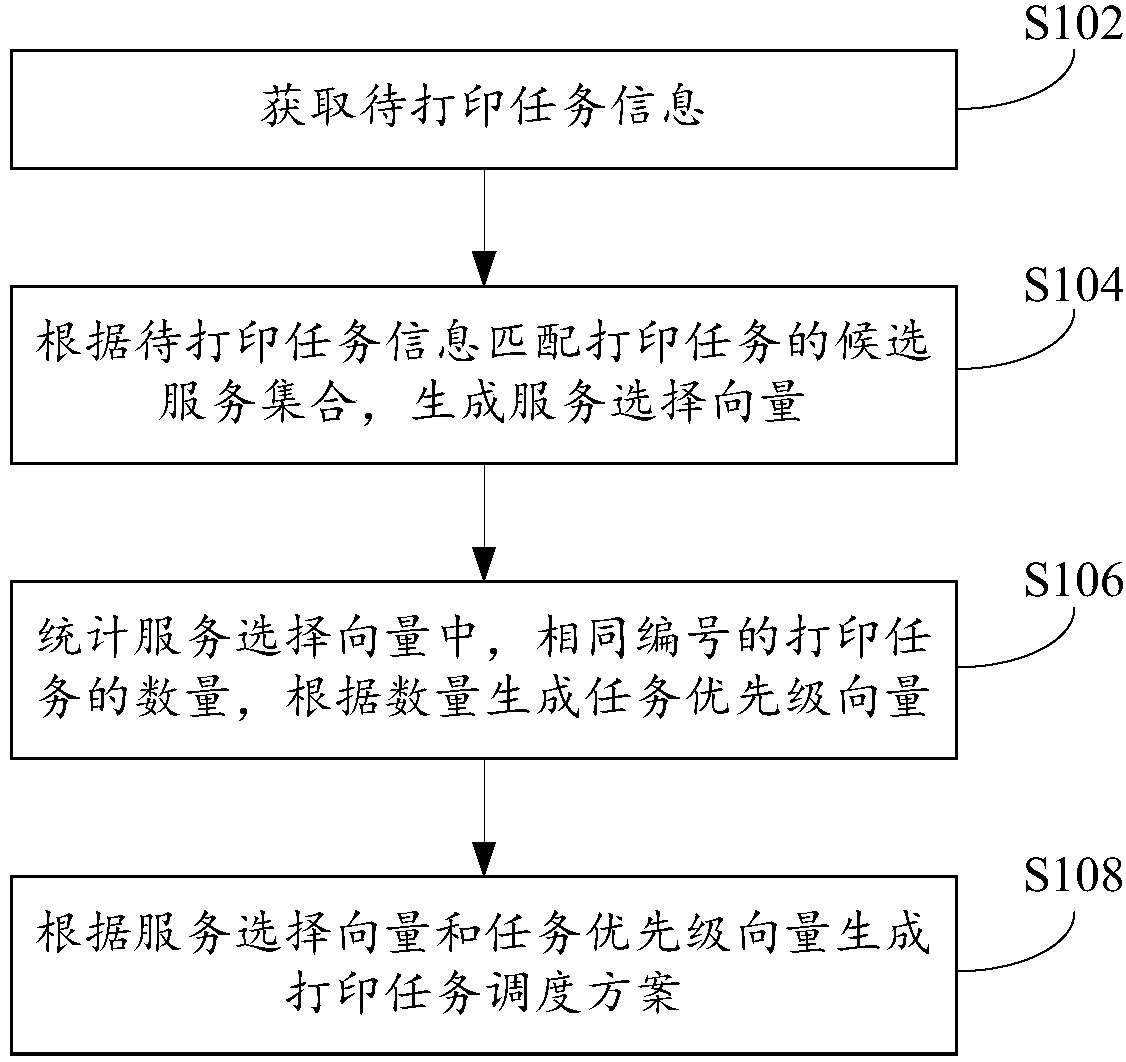

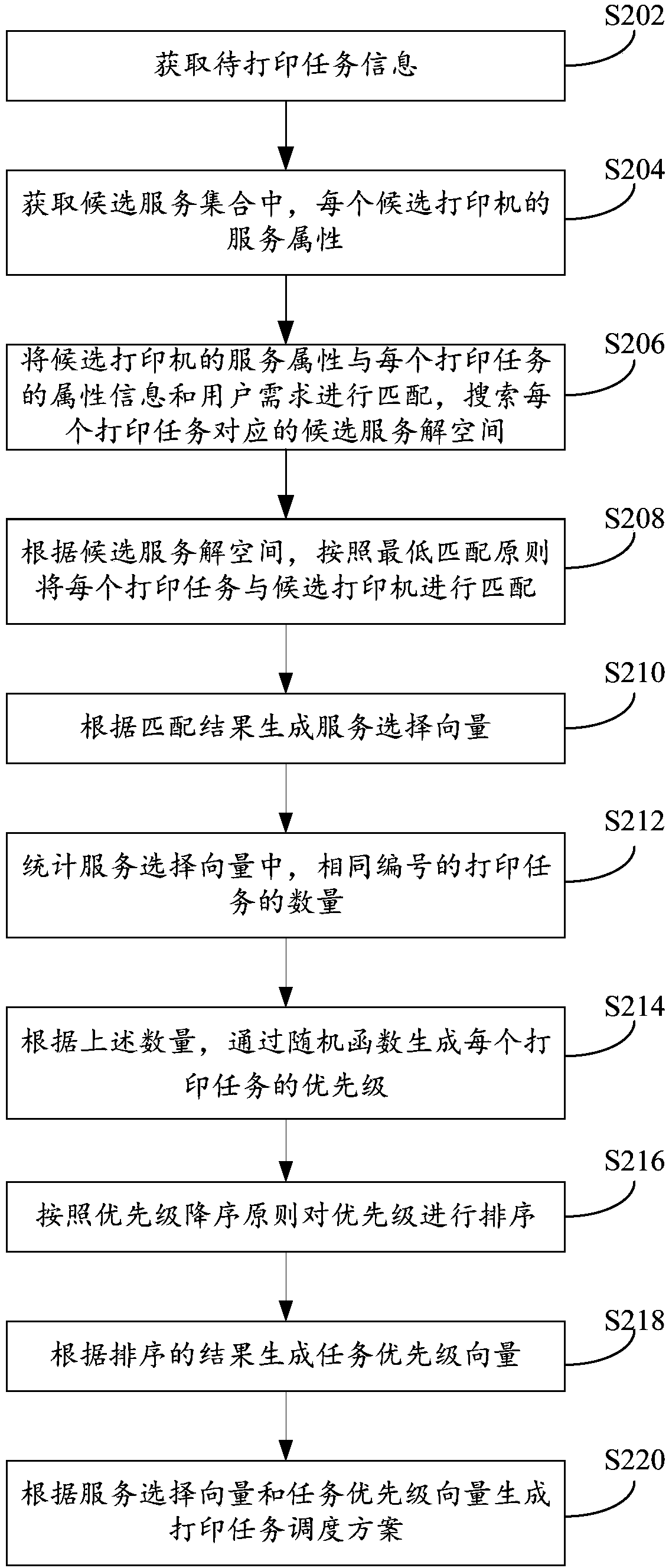

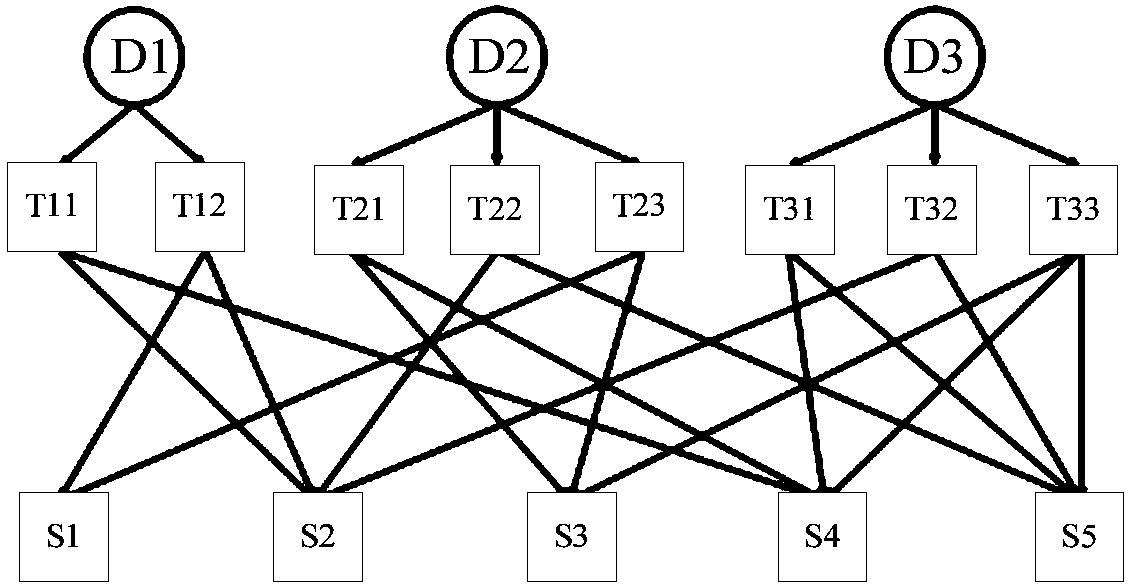

[0035] An embodiment of the present invention provides a printing task scheduling method, which can be applied on a server, wherein the printing task described in the embodiment of the present invention is a 3D printing task; the printer and the candidate printer described in the embodiment of the present invention are 3D printer. Such as figure 1 A flow chart of a printing task scheduling method is shown, including the following steps:

[0036] Step S102, acquiring task information to be printed;

[0037] Wherein, the above-mentioned to-be-printed task information includes the number of printing tasks, attribute information of each printing task, and user requirements; the number of printing tasks also includes the number of users and the number of printing tasks submitted by each user.

[0038] Step S104, generating a service selection vector by matching the candidate service set of the print job according to the job information to be printed;

[0039] Wherein, the above-...

Embodiment 2

[0094] On the basis of the above-mentioned embodiments, the embodiment of the present invention also provides a print job scheduling device, which can be set on a server, such as Figure 4 A schematic structural diagram of a printing task scheduling device is shown, the device includes:

[0095] The acquisition module 40 is configured to acquire information on tasks to be printed, wherein the information on tasks to be printed includes the number of print tasks, attribute information of each print task, and user requirements; wherein the number of print tasks also includes the number of users and the number of print jobs submitted by each user number of tasks;

[0096] The matching module 42 is used to match the candidate service set of the print task according to the task information to be printed, and generate a service selection vector; wherein, the candidate service set includes the service attribute of the candidate printer and the serial number of the candidate printer; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com