Method for making moisture-absorption and skin-friendly vortex colored spun yarn

A technology of vortex spinning and color spinning, applied in yarn, textile and papermaking, fiber processing, etc., can solve the problems of inability to meet fashion differentiation, meet customer demand restrictions, high prices, etc., and achieve the effect of satisfying fashion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

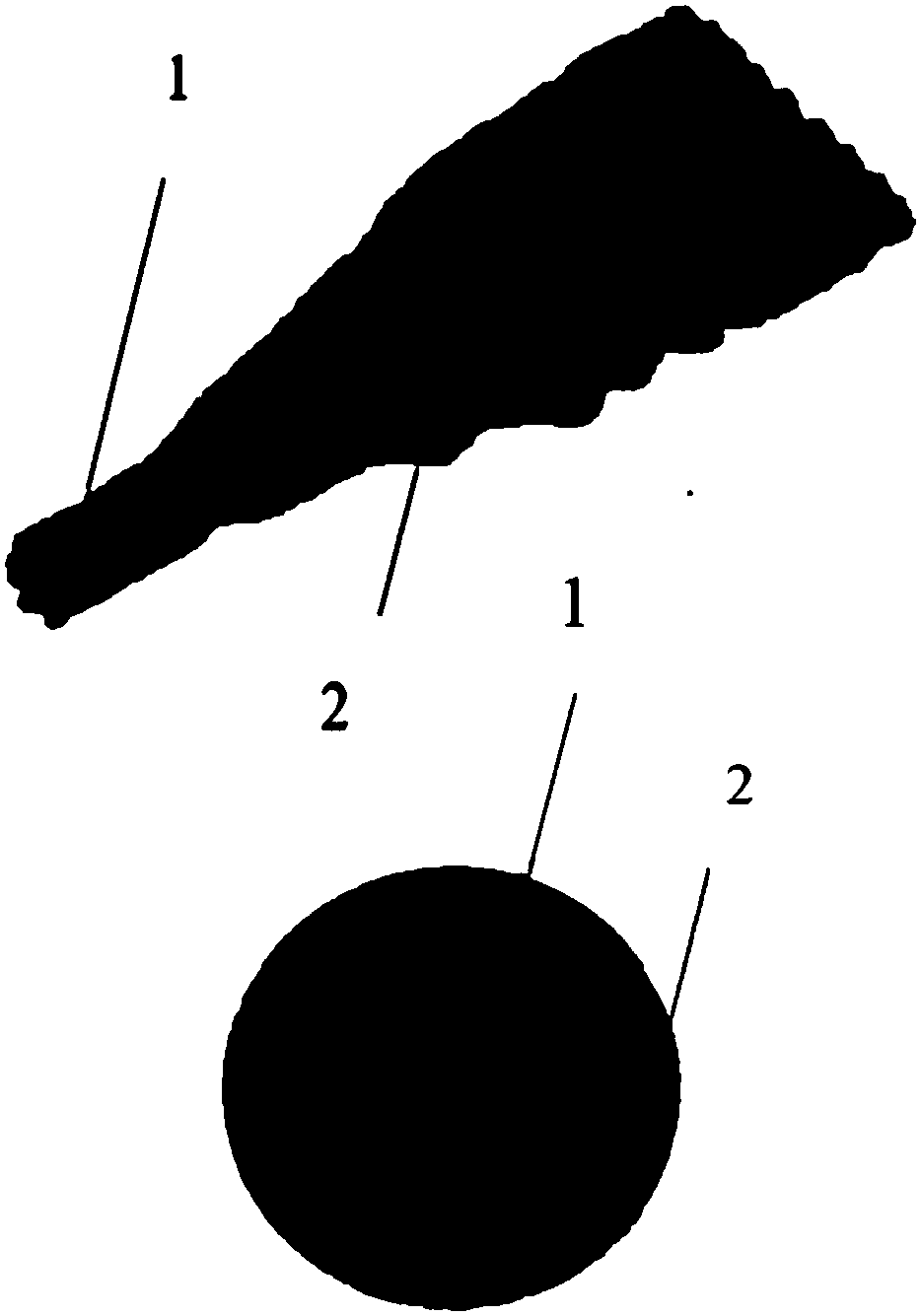

Image

Examples

Embodiment 1

[0028]A certain amount of white cotton is subjected to hygroscopic and skin-friendly treatment, and finally a hygroscopic and skin-friendly white cotton fiber with a pH value of 7 is obtained. The specific process is: the type of refining agent is GSF-5528, the concentration is 4g / l, the refining and smoothing agent (MS-111 of Yuyao Maitian Printing and Dyeing Auxiliary Company) is 3g / l, caustic soda is 4g / l, and the liquor ratio is 1:10. After immersing in a water bath at ℃ for 40 minutes, pickle until the pH value is 7. Then the fiber is dyed yellow to obtain a hygroscopic skin-friendly colored fiber, which is dried and loosened. After opening, the colored fiber is combed according to a specific ratio or requirement through carding and sliver winding process to obtain a moisture-absorbing and skin-friendly wet combed cotton sliver with a basis weight of 19.5g / 5m. White fine denier polyester (1.33dtex*38mm) is used for cotton blending, opening, carding and drawing to make pr...

Embodiment 2

[0030] A certain amount of white cotton is subjected to hygroscopic and skin-friendly treatment, and finally a hygroscopic and skin-friendly white cotton fiber with a pH value of 7 is obtained. The specific process is: the type of refining agent is GSF-5528, the concentration is 5g / l, the refining and smoothing agent (MS-111 of Yuyao Maitian Printing and Dyeing Auxiliary Company) is 3.5g / l, caustic soda is 3g / l, and the liquor ratio is 1:10. After immersing in a 60°C water bath for 35 minutes, pickle until the pH value is 7. Then the fibers are dyed black to obtain hygroscopic and skin-friendly colored fibers, which are dried and loosened. After opening, the moisture-absorbing skin-friendly fiber and ordinary white cotton fiber are mixed according to the ratio of 30%:70%, and then carded and slivers are combed to obtain a moisture-absorbing skin-friendly combed cotton sliver with a basis weight of 19.5g / 5m. White fine denier modal (1.3dtex*39mm) is used for cotton blending, o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com