Novel hydraulic bulging test clamp

A technology of hydraulic bulging and test fixtures, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of uneven sample clamping, inaccurate measurement, poor safety, etc., to reduce the time used, high measurement reliability, Even clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

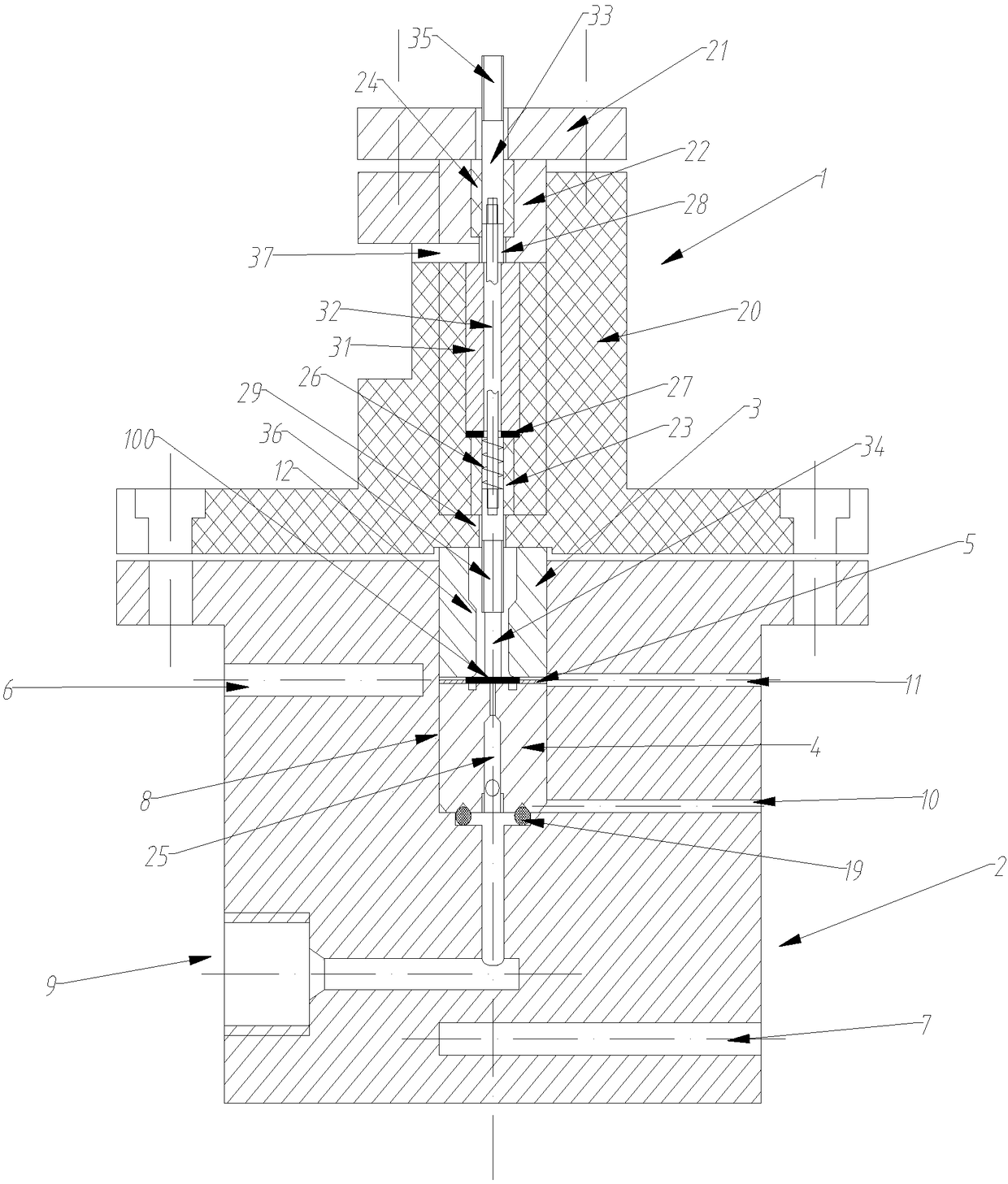

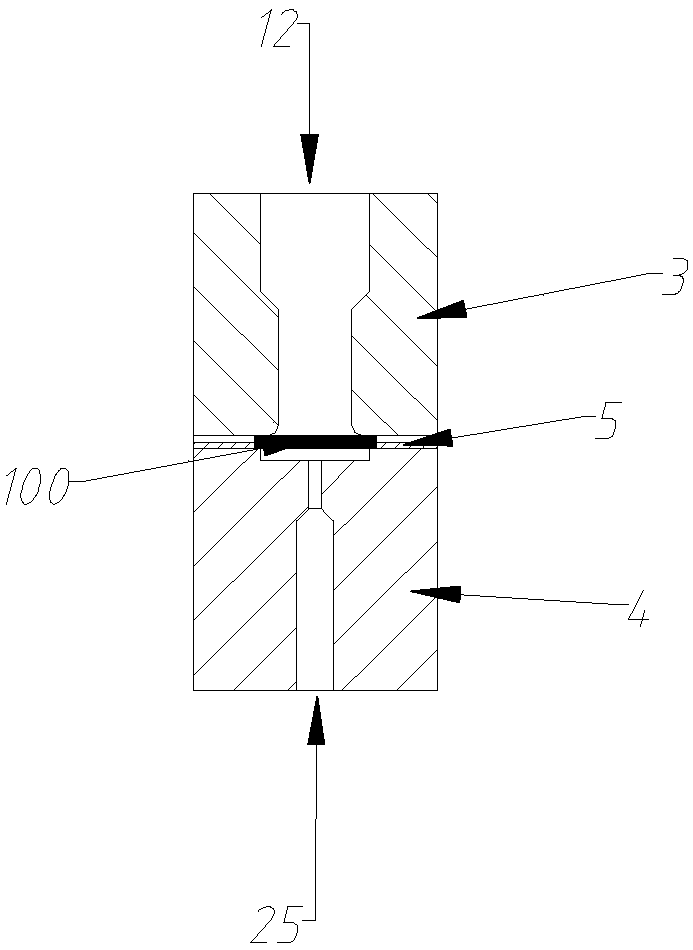

[0033] Such as figure 1 As shown, the new hydraulic inflation test fixture includes an upper fixture 1 , a lower fixture 2 , an upper sleeve 3 and a lower sleeve 4 .

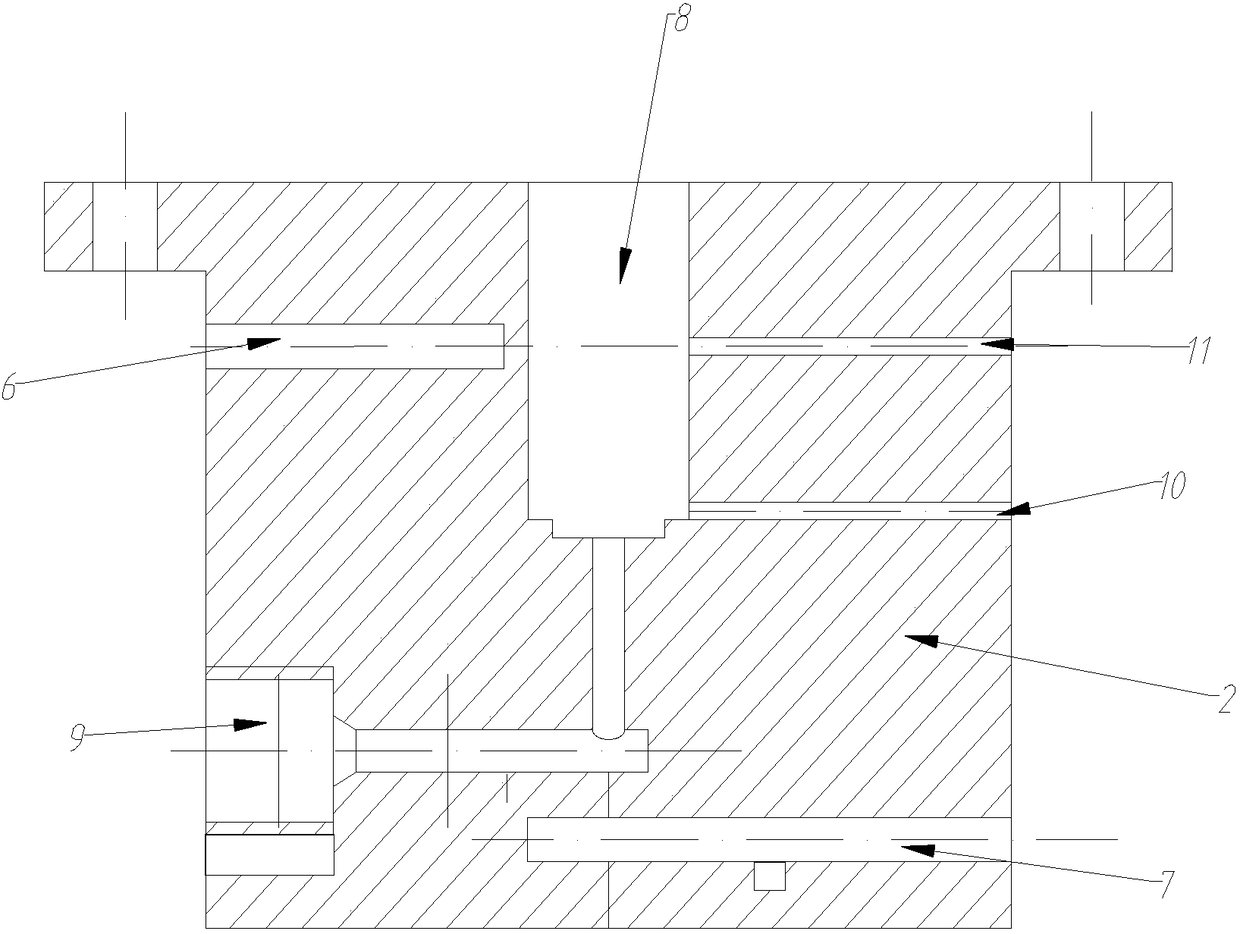

[0034] Such as figure 2 As shown, the lower fixture 2 is cylindrical, the upper edge of the lower fixture 2 is provided with a flange, and the flange and the lower fixture 2 body are integrally formed, and the center of the upper part of the lower fixture 2 is vertically provided with an inwardly extending installation cavity 8. The inner wall surface of the installation cavity 8 is smooth, and the installation cavity 8 is used to fix the upper sleeve 3 and the lower sleeve 4 . The installation cavity 8 is processed once, so as to ensure that the upper sleeve 3 and the lower sleeve 4 are coaxial. One side of the lower clamp 2 is respectively horizontally provided with a first oil drain passage 11 and a second oil drain passage 10 extending inward, and the first oil drain passage 11 and the second oil drain pa...

Embodiment 2

[0048] This embodiment is based on Embodiment 1, and the difference between this embodiment and Embodiment 1 is that a temperature-measuring blind hole 6 is horizontally arranged on the lower fixture 2 in this embodiment, and the diameter of the temperature-measuring blind hole 6 is 1 ~8mm, the hole depth of the temperature measuring blind hole 6 is 10-20mm smaller than the radius of the lower fixture 2, a temperature sensor can be installed in the temperature measuring blind hole 6 for measurement, and the temperature sensor is used to measure the temperature of the hydraulic oil in the test.

Embodiment 3

[0050] The structures of the lower clamp 2, the upper sleeve 3 and the lower sleeve 4 in this embodiment are the same as those in Embodiment 2. The difference between this embodiment and Embodiment 2 is that the upper clamp 1 in this embodiment only includes The upper fixture body 20, the upper fixture body 20 is a flange sealing plate, and the flange sealing plate is connected to the lower fixture 2 through a flange. The new hydraulic bulging test fixture in this embodiment is suitable for the situation where it is not necessary to measure the deformation of the sample 100 during the test. Compared with the new hydraulic bulging test fixture in Example 2, the new hydraulic bulging test fixture in this embodiment has a more structured structure. Simple and easy to install.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com