Pixel circuit, driving method thereof and display device

A pixel circuit and capacitor technology, applied in static indicators, instruments, etc., can solve the problems of uneven display and unstable grid voltage of display devices, and achieve stable current, grid voltage, and uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

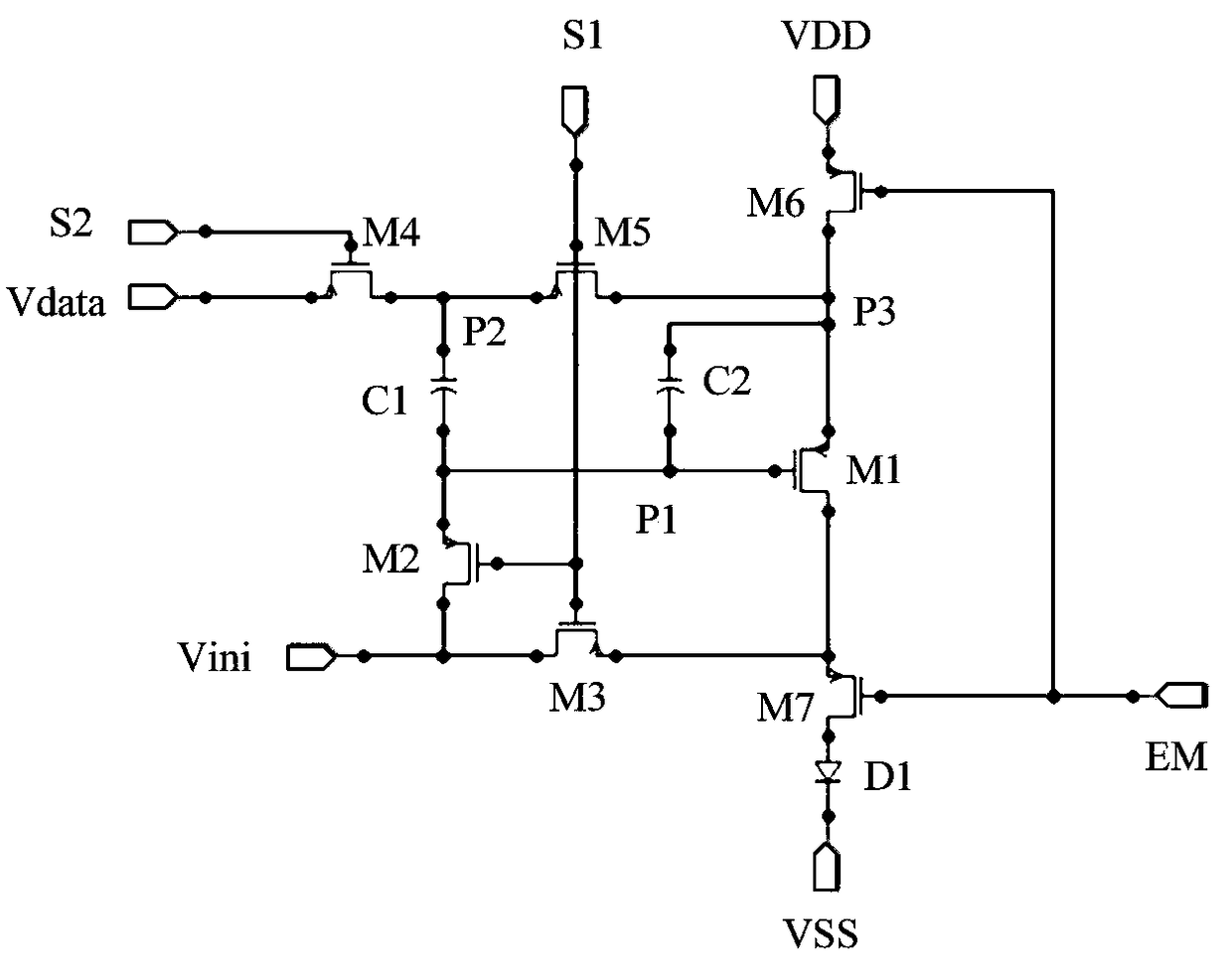

[0043] figure 1 A schematic structural diagram of a pixel circuit provided in an embodiment of the present application. The pixel circuit is as follows.

[0044] Such as figure 1 As shown, the pixel circuit includes a first thin film transistor M1, a second thin film transistor M2, a third thin film transistor M3, a fourth thin film transistor M4, a fifth thin film transistor M5, a sixth thin film transistor M6, a seventh thin film transistor M7, The first capacitor C1, the second capacitor C2 and the light emitting diode D1.

[0045] in, figure 1 In the pixel circuit shown, the first thin film transistor M1, the second thin film transistor M2, the third thin film transistor M3, the fourth thin film transistor M4, the fifth thin film transistor M5, the sixth thin film transistor M6 and the seventh thin film transistor M7 are all P-type thin film transistor, light emitting diode D1 is OLED.

[0046] figure 1 The circuit connection structure of the pixel circuit shown is a...

Embodiment 2

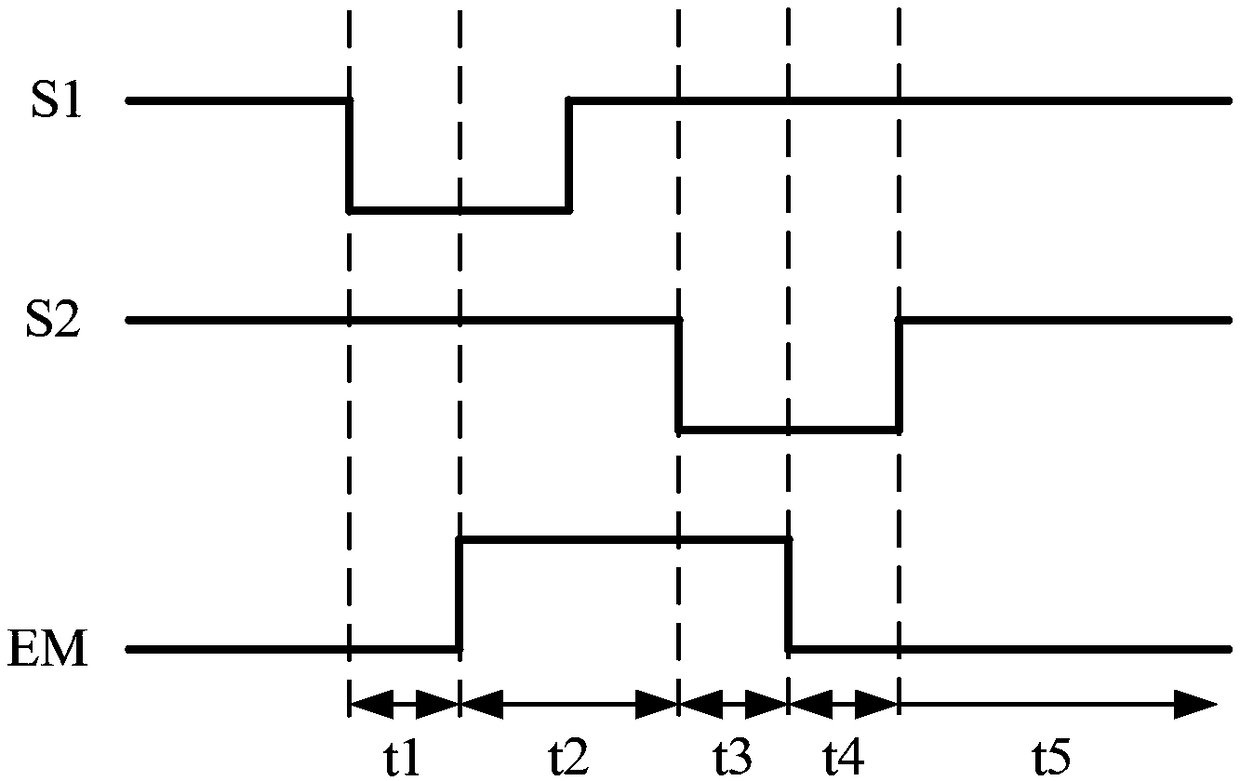

[0071] figure 2 A timing diagram of a pixel circuit driving method provided in an embodiment of the present application, the pixel circuit driving method corresponding to the timing diagram can be used to drive figure 1 The pixel circuit shown.

[0072] figure 2 The driving method of the pixel circuit corresponding to the timing diagram shown may include five stages: the first stage t1, the second stage t2, the third stage t3, the fourth stage t4 and the fifth stage t5, wherein, S1 may be figure 1 The first scanning signal provided by the first scanning line described in the illustrated embodiment, S2 may be figure 1 The second scanning signal provided by the second scanning line described in the illustrated embodiment, EM may be figure 1 The light emission control signal provided by the light emission control line described in the illustrated embodiment.

[0073] figure 2 The driving method of the pixel circuit corresponding to the timing diagram shown specifically in...

Embodiment 3

[0116] An embodiment of the present application further provides a display device, which may include the pixel circuit described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com