Pile foundation construction parameter monitoring system and monitoring method of long spiral drilling machine

A technology of long auger drilling rig and construction parameters, which is applied to the automatic control system of drilling, transmission system, infrastructure engineering, etc., can solve problems such as reducing construction efficiency, and achieve the effect of convenient monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the drawings:

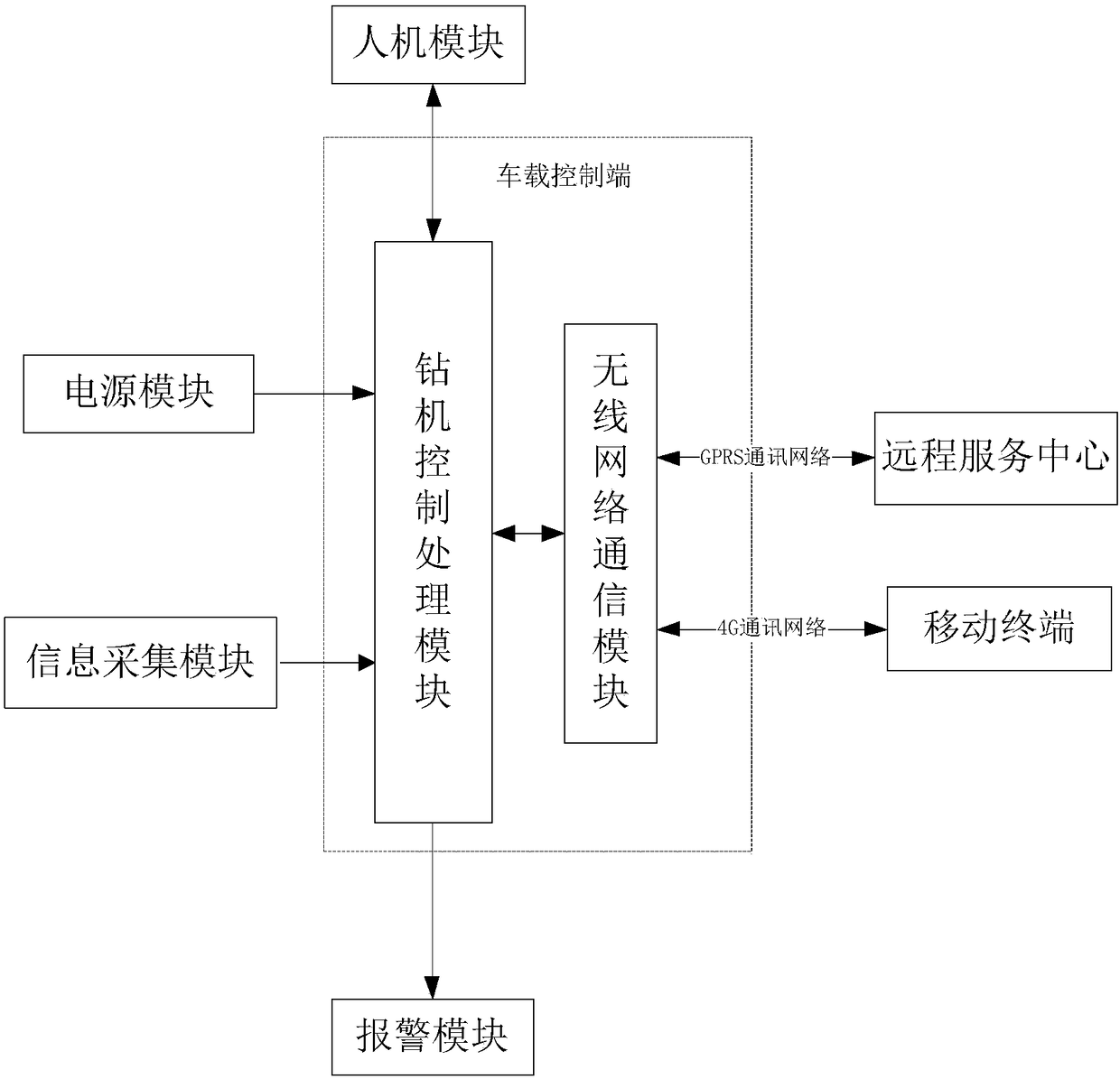

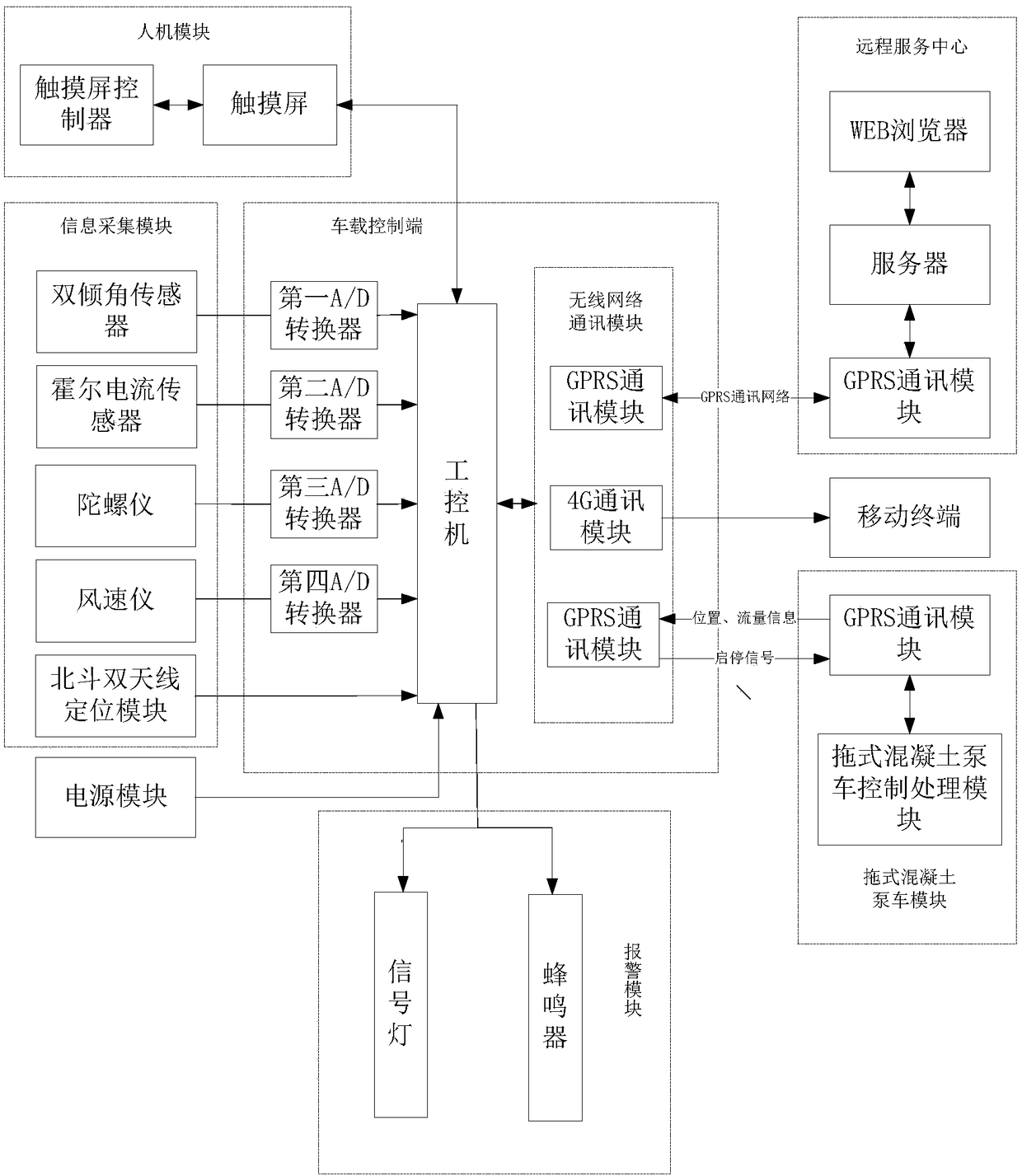

[0024] See Figure 1-Figure 2 , A long auger drilling rig pile foundation construction parameter monitoring system, including a vehicle control terminal, a man-machine module, an information acquisition module and a remote service center; the vehicle control terminal includes a drilling rig control processing module and a wireless network communication module, a man-machine module, and information collection Both the module and the remote service center are connected to the drilling rig control processing module; the drilling rig control processing module is used to receive, process, and store the sensor information transmitted by the information acquisition module, and display the processing results on the touch screen of the drilling rig operating room in real time. The processing results corresponding to each pile are transmitted to the remote service center through the wireless ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com