Preparation method of fermented soft ice cream slurry

A technology of soft ice cream and slurry, which is applied in frozen desserts, food ingredients as thickeners, food science, etc. It can solve the problems of whey precipitation, failure to store at room temperature, fat crystallization, etc., and achieve no ice crystal feeling and protect the gel The effect of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

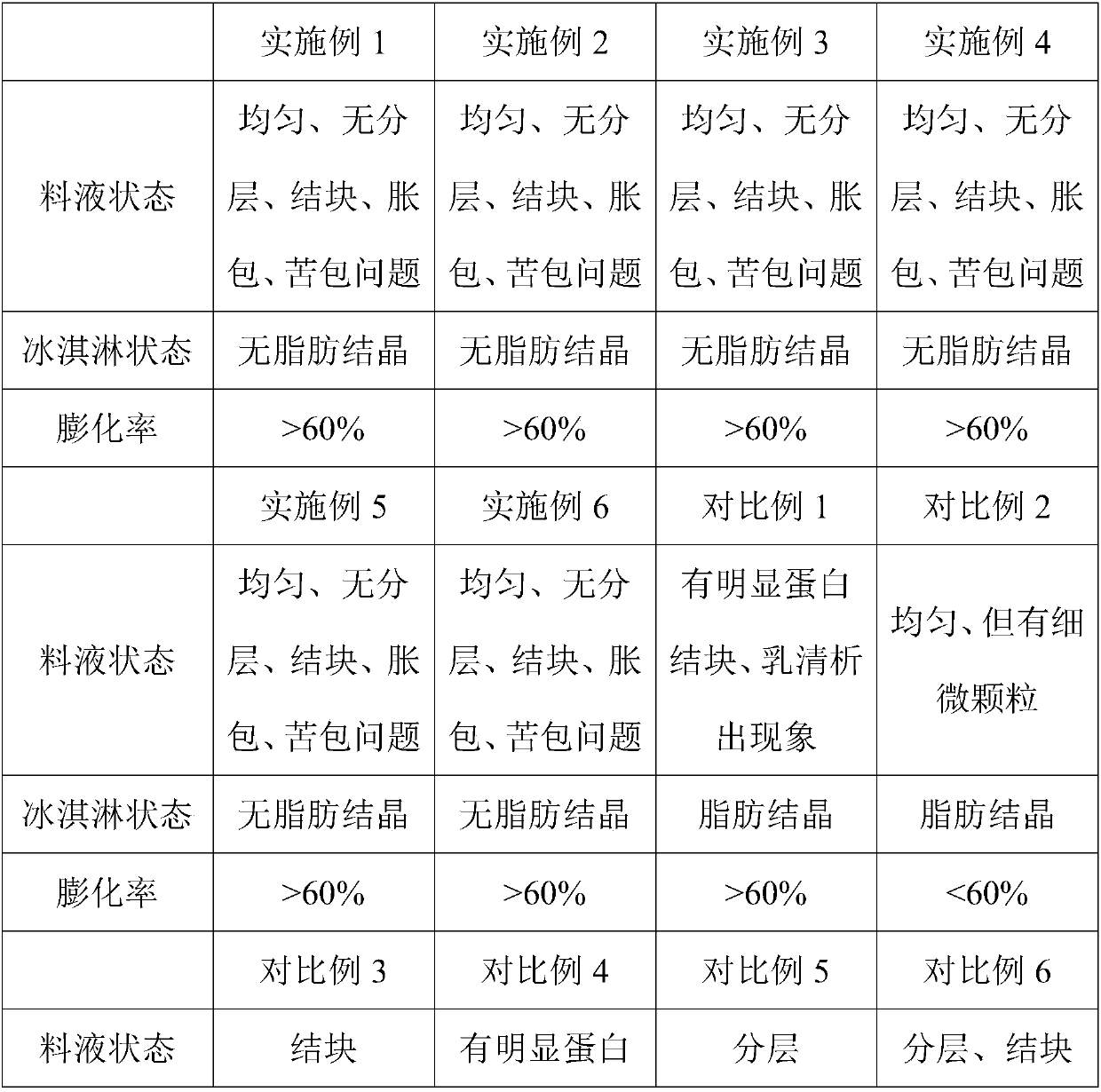

Embodiment 1

[0054] The soft ice cream slurry provided in this embodiment is composed of the following raw materials:

[0055] Whole milk powder 120g, butter 30g, white sugar 100g, maltose syrup 80g, glyceryl monostearate 1.5g, gelatin 6g, alginate propylene glycol fat 0.4g, xanthan gum 1.2g, pectin 3g Yogurt flavor 2g, Lactobacillus bulgaricus 0.03g, drinking water 813.77g.

[0056] Put whole milk powder into drinking water for hydration, the hydration temperature is 45℃, and the hydration time is 1h;

[0057] Heat the hydrated liquid to 55°C, add glyceryl monostearate, gelatin, propylene glycol alginate, xanthan gum and pectin, mix well, then add white sugar, maltose syrup, butter, yogurt flavor , Use the high-speed stirring circulation system to fully stir and dissolve for 30 minutes;

[0058] Heat the mixed material liquid to 75°C for homogenization, and the homogenization pressure is 15MPa;

[0059] Heat the homogenized material liquid to 92°C for sterilization, and the sterilization time is ...

Embodiment 2

[0065] The soft ice cream slurry provided in this embodiment is composed of the following raw materials:

[0066] Raw milk 803.79g, skimmed milk powder 20g, coconut oil 30g, white sugar 130g, glyceryl monostearate 1.8g, gelatin 5g, alginate propylene glycol fat 0.6g, xanthan gum 0.8g, pectin 5g Yogurt flavor 3g, Lactobacillus acidophilus 0.01g.

[0067] Put skimmed milk powder into raw milk for hydration, the hydration temperature is 50℃, and the hydration time is 0.5h;

[0068] Heat the hydrated liquid to 58℃, add glyceryl monostearate, gelatin, propylene glycol alginate, xanthan gum and pectin, mix well, then add white sugar, coconut oil, yogurt flavor, and use High-speed stirring circulation system fully stirs and dissolves for 35min;

[0069] Heat the mixed material to 80°C for homogenization, and the homogenization pressure is 20MPa;

[0070] Heat the homogenized material liquid to 100°C for sterilization, and the sterilization time is 320s;

[0071] Cool the sterilized material l...

Embodiment 3

[0076] The soft ice cream slurry provided in this embodiment is composed of the following raw materials:

[0077] Drinking water 661.65g, skimmed milk powder 100g, coconut oil 60g, white sugar 120g, maltose syrup 40g, glyceryl monostearate 2.5g, gelatin 4g, propylene glycol alginate 1.2g, xanthan gum 0.6g, pectin 6g Yogurt flavor 4g, Lactococcus lactis subsp. lactis 0.05g.

[0078] Put the skimmed milk powder into drinking water for hydration, the hydration temperature is 55℃, and the hydration time is 1h;

[0079] Heat the hydrated liquid to 65°C, add glyceryl monostearate, gelatin, propylene glycol alginate, xanthan gum and pectin, mix well, then add white sugar, maltose syrup, coconut oil, yogurt Essence, use high-speed stirring circulation system to fully stir and dissolve for 40 minutes;

[0080] Heat the mixed material to 76°C for homogenization, and the homogenization pressure is 19MPa;

[0081] Heat the homogenized material liquid to 95°C for sterilization, and the sterilizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com