Radiation-conveniently textile machine

A textile machine and heat dissipation device technology, which is applied in textiles, looms, textiles and papermaking, etc., can solve the problems of easy heat, poor applicability and practicality, and easy overheating damage of textile machines, so as to achieve good shock absorption effect and improve quality , the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

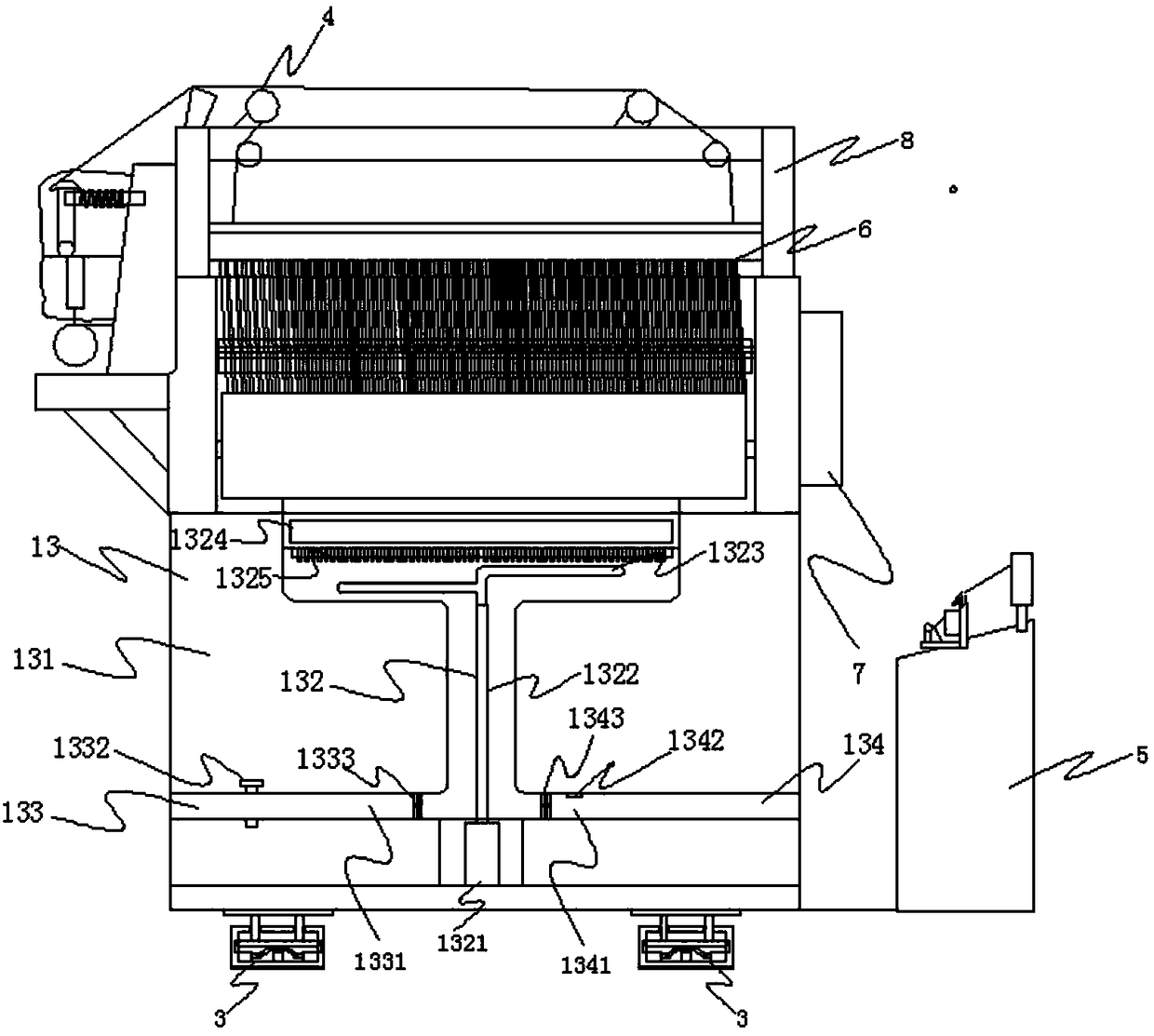

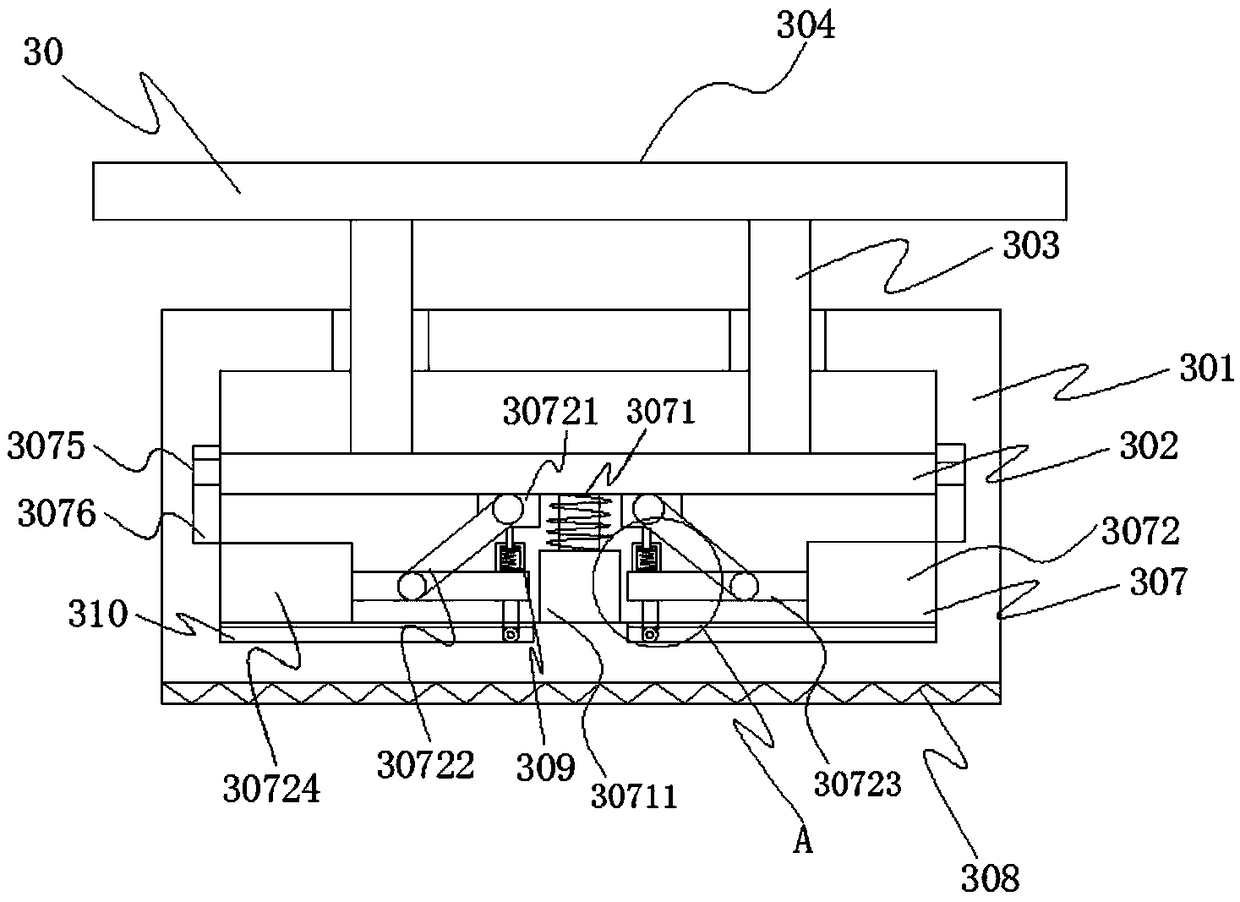

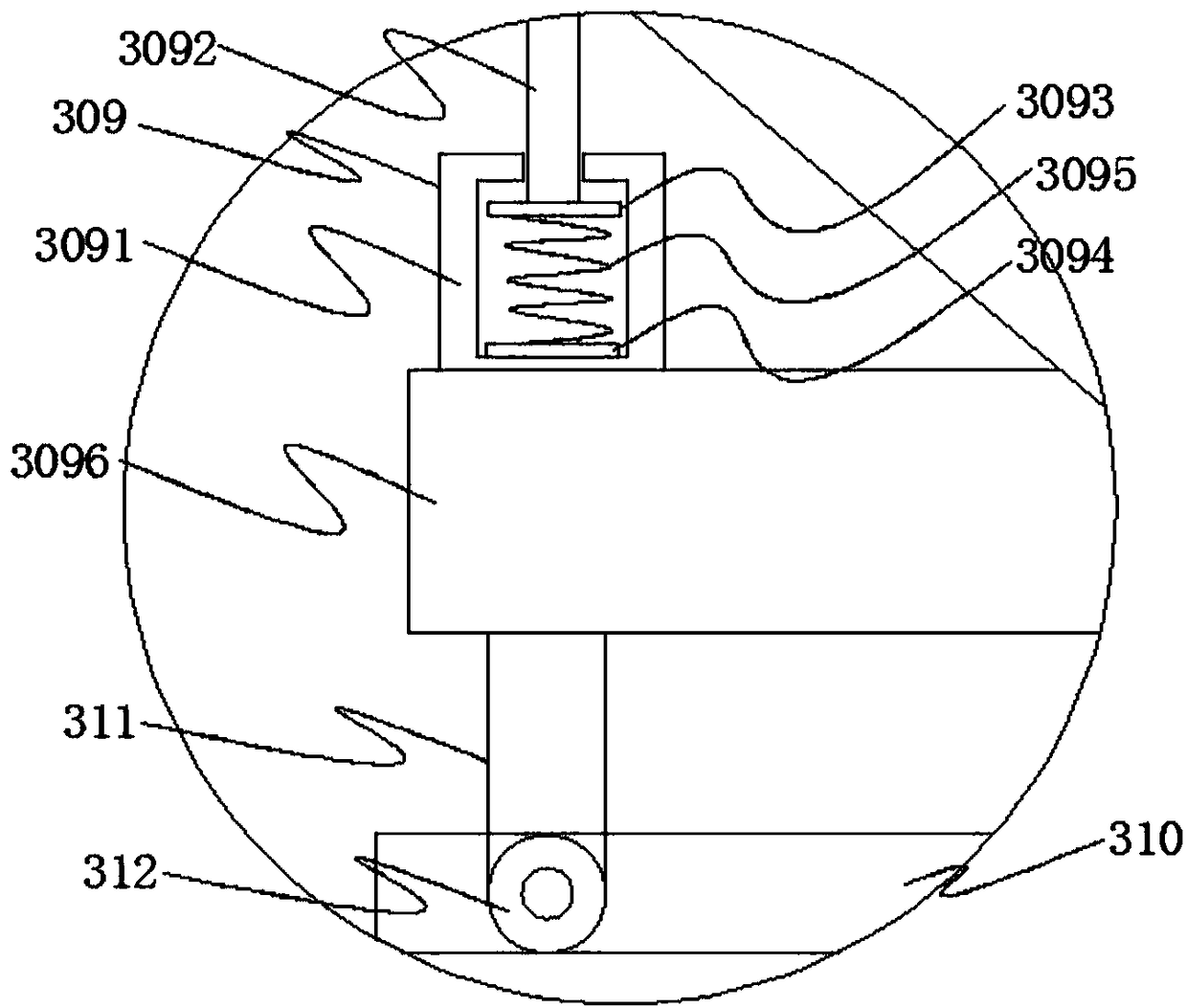

[0020] like Figure 1-5 As shown, a textile machine that is convenient for heat dissipation includes a frame 1, a base 2, a shock absorber 3, a traction device 4, a conveying device 5, a detection device 12, a needle selection device 6 and a heat dissipation device 13, and the base 2 is set On the frame 1, the shock absorbing device 3 is arranged on the base 2, wherein the detection device 12 is used to detect whether the yarn breakage phenomenon 12 occurs during the working process of the textile machine, and the heat dissipation device 13 includes a shell 131, a central heat dissipation assembly 132. The air exhaust assembly 133 and the heat exhaust assembly 134 dissipate h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com