Brake pad wear condition detection system and method

A detection system and brake pad technology, applied in the direction of brake safety system, brake type, mechanical equipment, etc., can solve problems such as increased cost, hidden safety hazards, and difficulty in timely discovery, and achieve low long-term use costs, accurate detection results, and improved The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

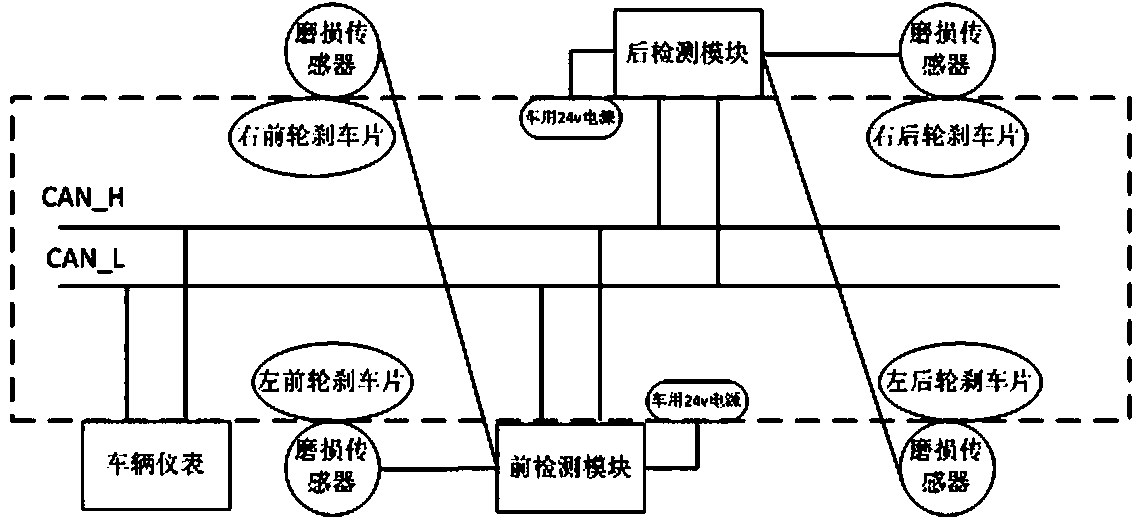

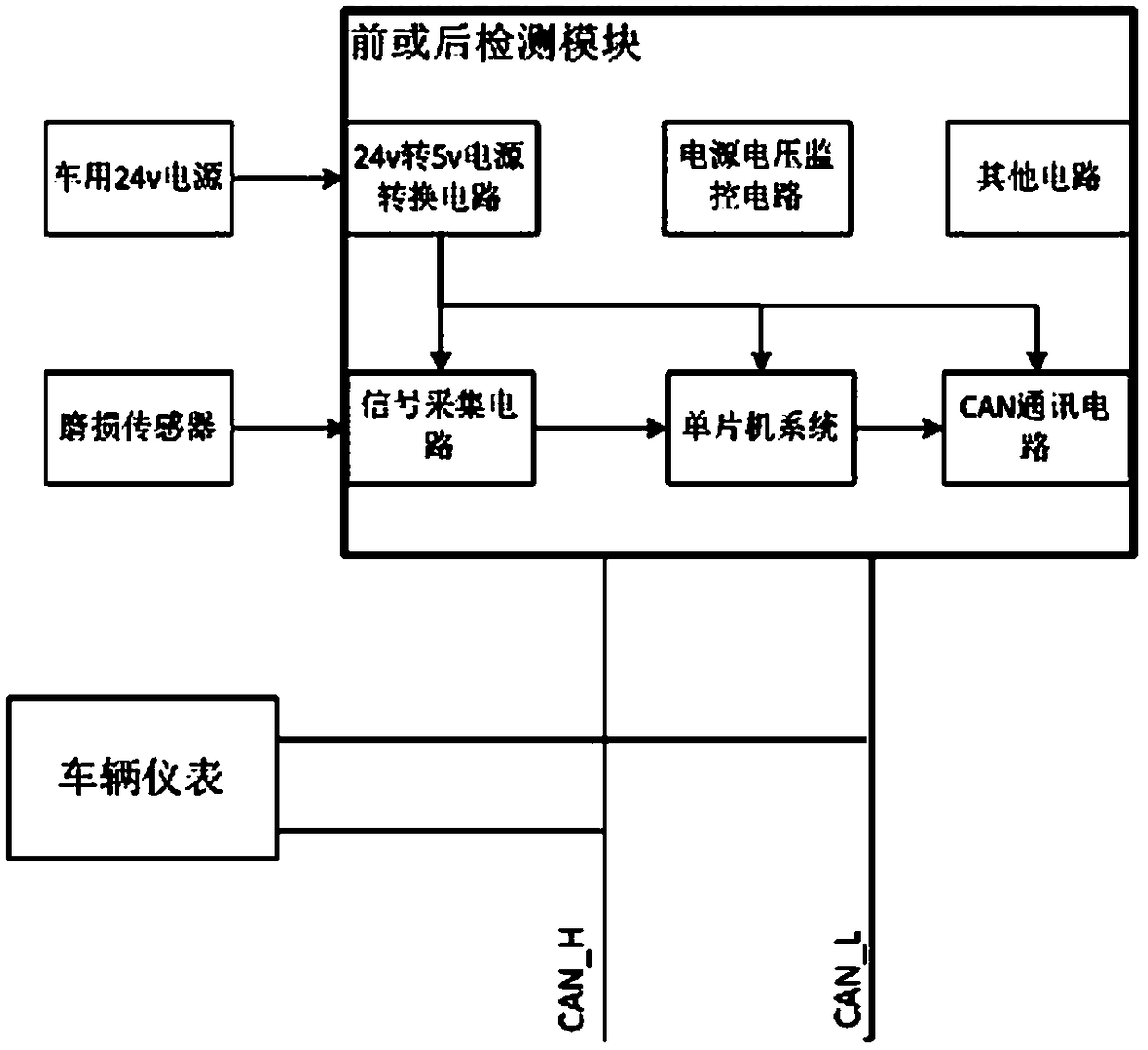

[0037] like Figure 1 to Figure 3 As shown, the present embodiment is a brake pad wear detection system, including:

[0038] 4 wear sensors, 24V power supply for vehicle, front detection module, rear detection module, vehicle CAN bus, vehicle instrument;

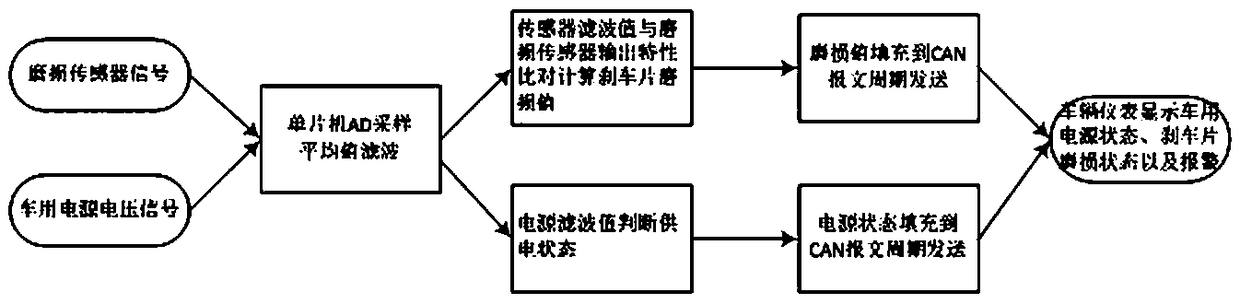

[0039] Wherein, the four wear sensors are respectively mounted on the drum brakes of the left wheel of the front axle, the right wheel of the front axle, the left wheel of the rear axle, and the right wheel of the rear axle, and are angle sensors for measuring the angle of the self-adjusting arm of the axle brake; Specifically, the BRASS LINING WEAR SENSOR produced by Haldex Company has 4 terminals, which are 1 5V power input terminal, 2 signal output terminals, and 1 ground terminal; the basic principle is that the brake pads wear more More, the larger the axle brake self-adjusting arm angle is, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com