Oscillating bar oscillating tooth speed reducer with clearance eliminating mechanism

A movable tooth reducer and backlash elimination technology, applied in the direction of gear vibration/noise attenuation, mechanical equipment, gear transmission, etc., can solve the problems of generating axial force, impact, affecting transmission performance, etc. The effect of precise clearance adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

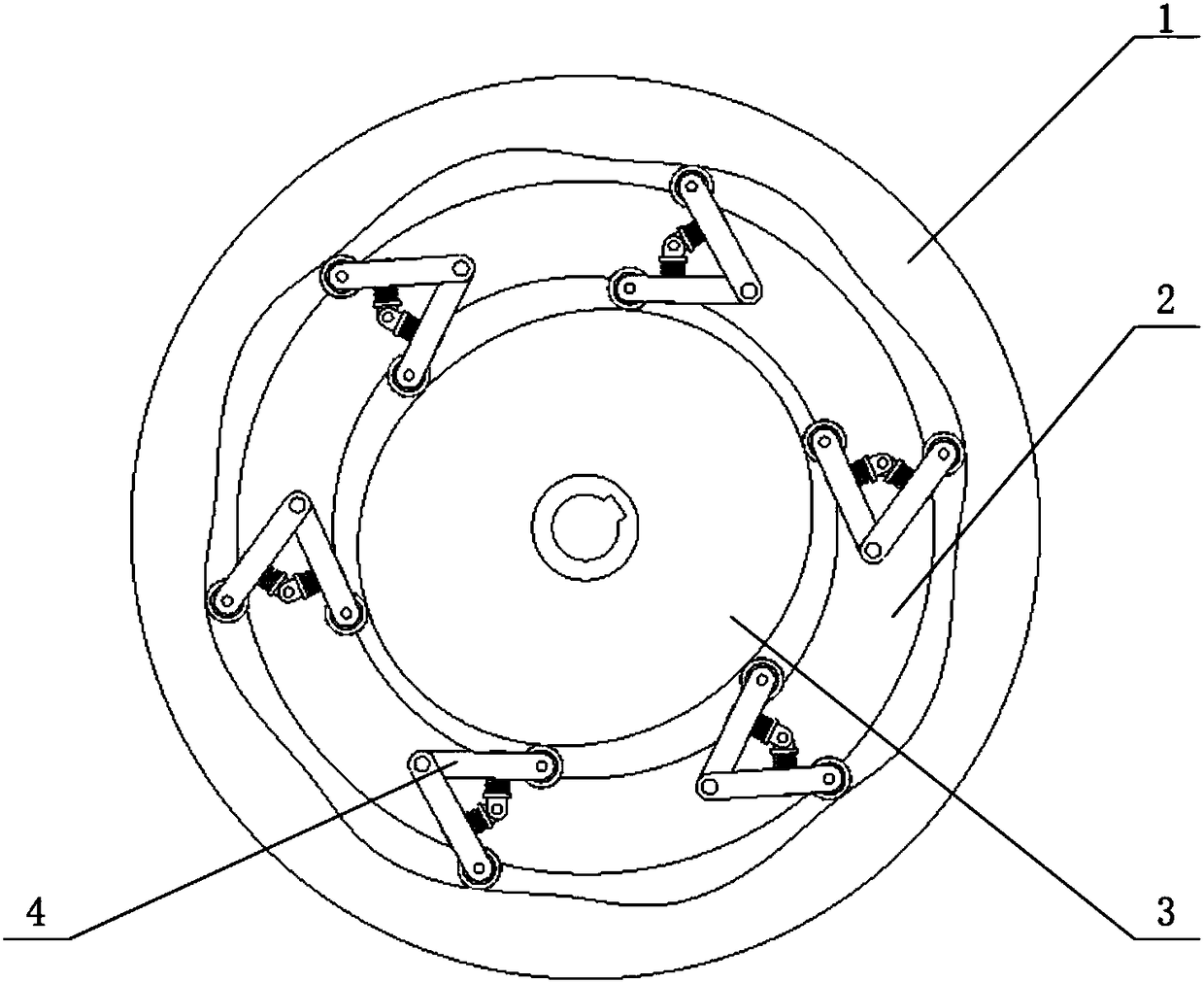

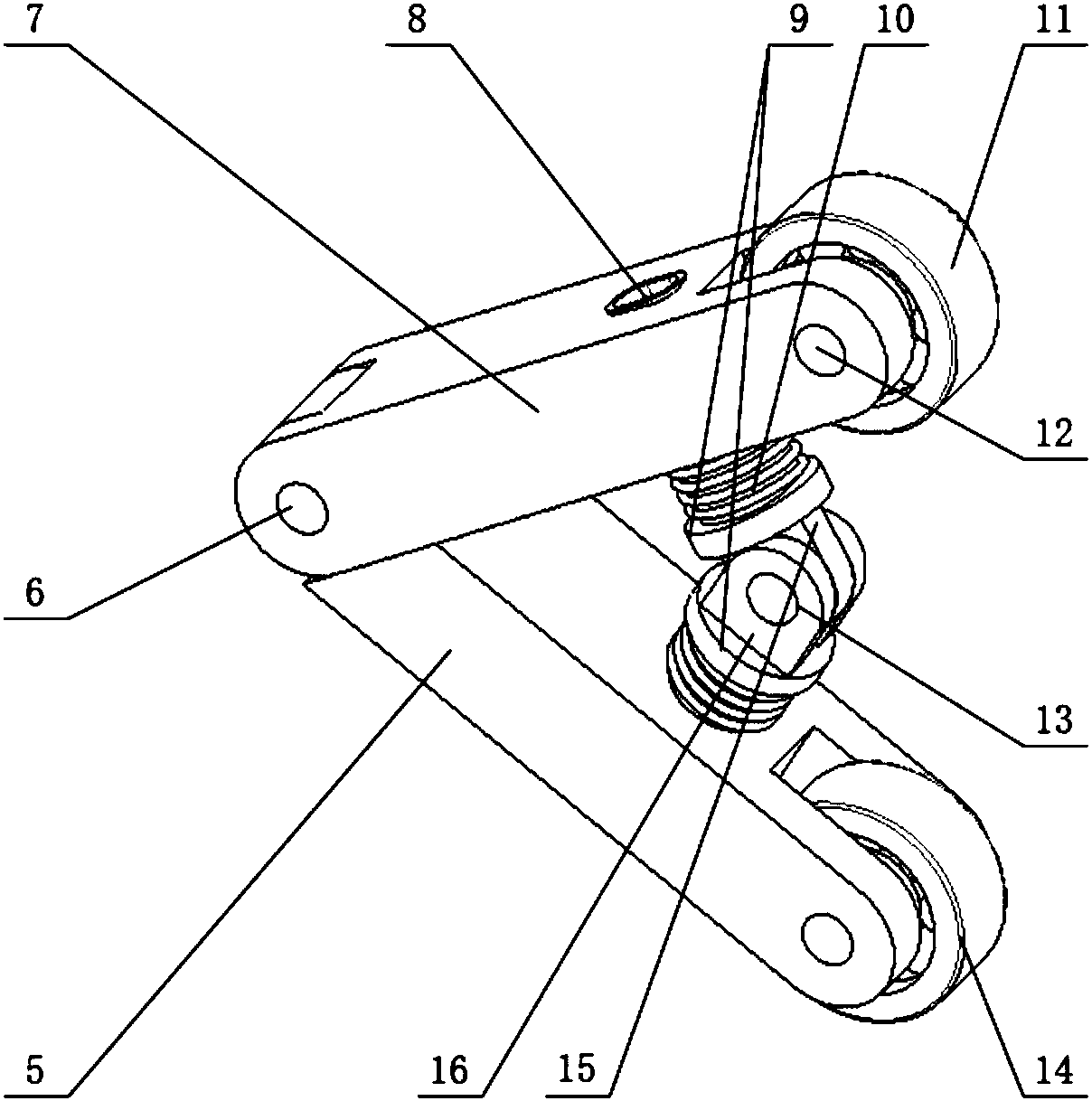

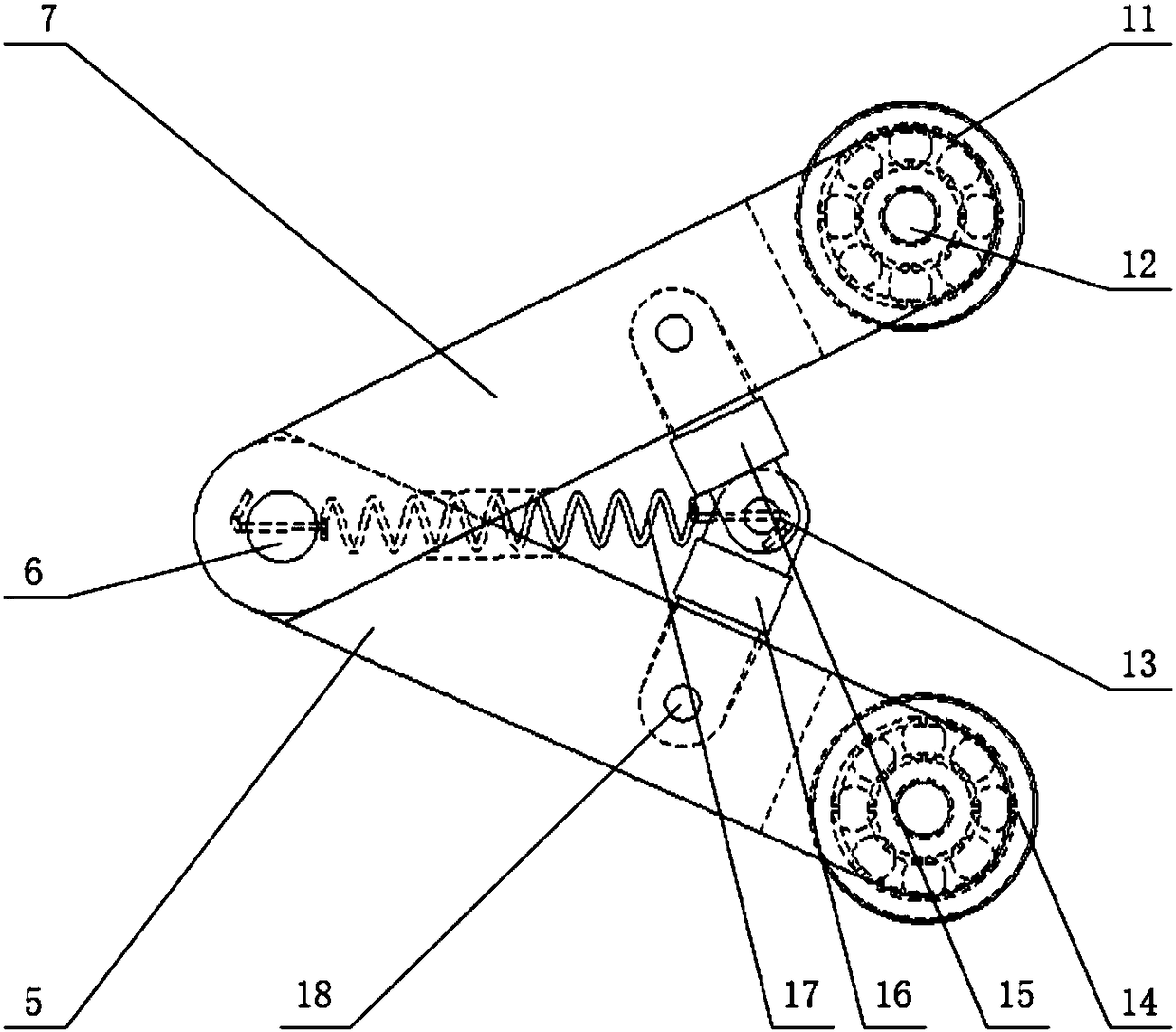

[0013] exist figure 1 In the schematic diagram of the front view of the swing rod movable tooth reducer with the anti-backlash mechanism shown, the center wheel 1 is a disc with a central through hole, and one end surface is provided with a groove, and the inner wall of the groove is in the shape of a tooth. The center through hole is provided with an elliptical shock wave device 3 coaxial with it and the outer end face is flush with the end face of the center wheel, and the end face is lower than the center at the position between the inner tooth profile of the center wheel and the outer peripheral surface of the shock wave device. Wheel end face and internal diameter are greater than the large diameter of the shock wave device, the outer diameter is less than the annular movable gear frame 2 of internal tooth profile, be provided with 6 evenly distributed swing rod movable teeth 4 on this movable gear frame. The movable tooth of the swing rod mainly includes an upper member ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com