Automobile vibration test device

A technology for vibration testing and automobiles, which is applied in vibration testing, measuring devices, and vehicle testing. It can solve problems such as fewer testing devices, low testing accuracy, and less degrees of freedom, so as to reduce testing time, improve testing effects, and achieve freedom. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

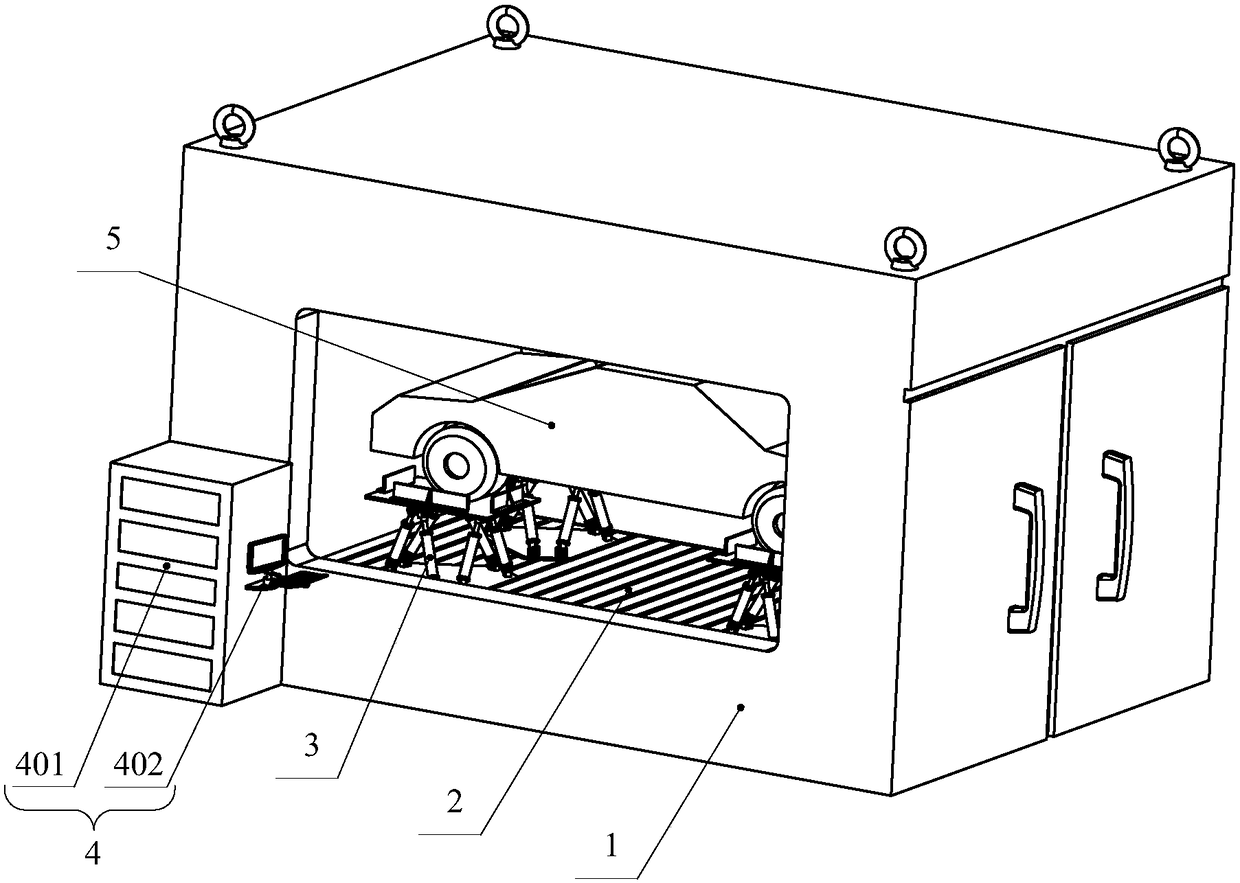

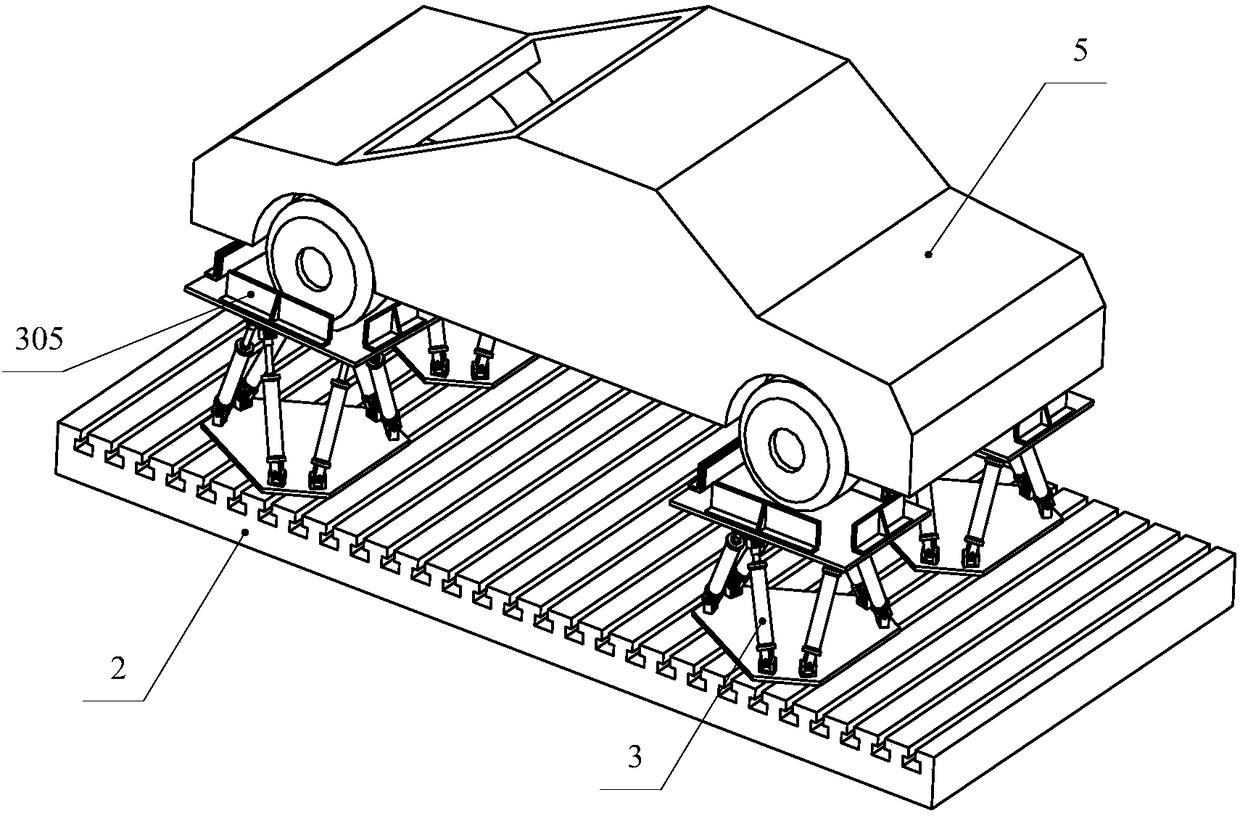

[0024] Such as figure 1 As shown, an automobile vibration test device is mainly composed of an environmental chamber (1), an installation floor (2), a Stewart parallel mechanism (3), a control system (4) and a hydraulic drive system (not marked).

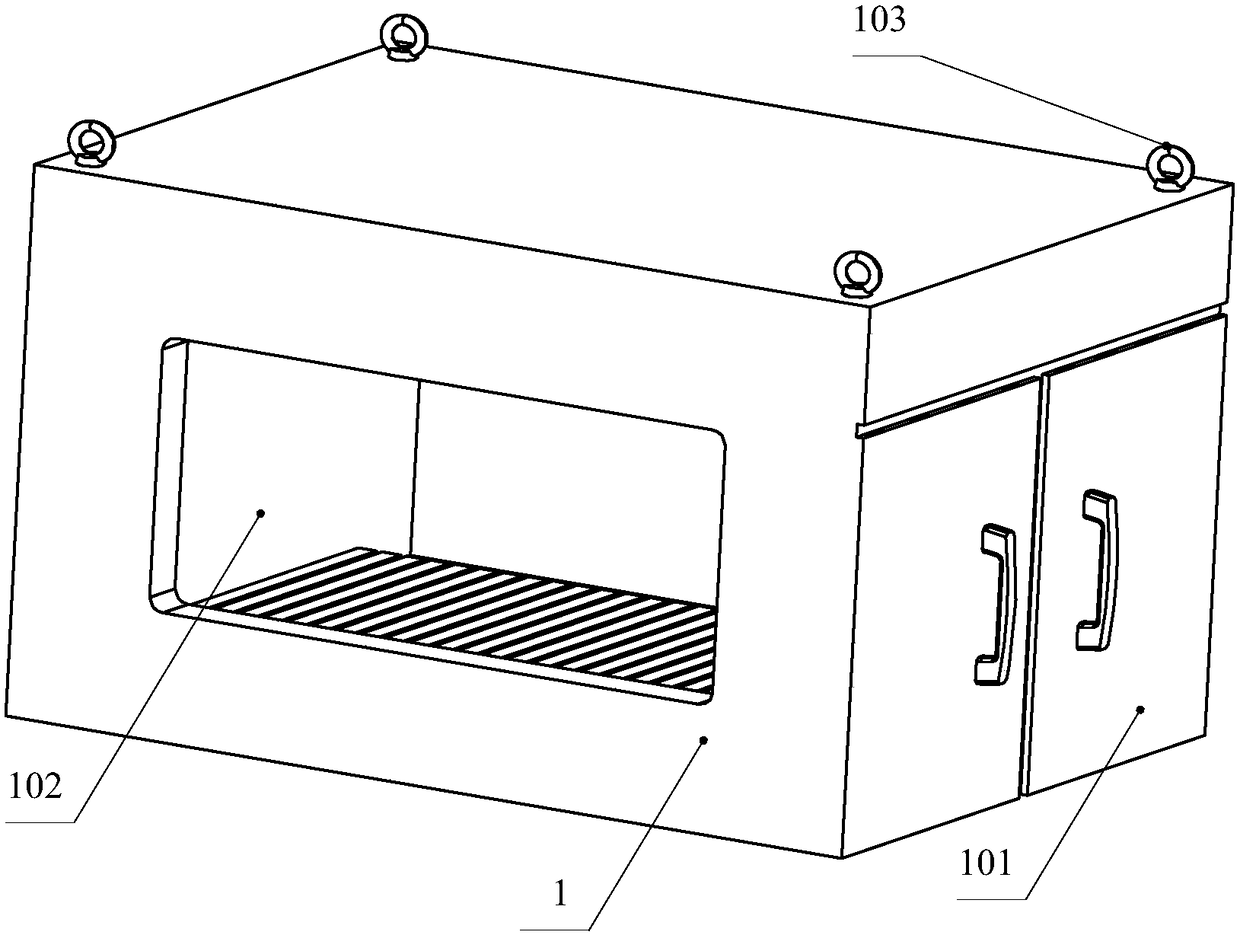

[0025] Such as figure 1 with figure 2 As shown, the environmental cabin (1) integrates temperature, humidity and light adjustment equipment, which can realize the control of environmental factors such as temperature, humidity, and light radiation in the cabin.

[0026] Such as figure 1 with figure 2 As shown, a cabin door (101) is installed on the side wall on one side of the length direction of the environmental cabin (1) to allow test vehicles and personnel to enter and exit; an observation window is left on the side wall on the side of the width direction of the environmental cabin (102) is used to observe the test status; the four corners of the top of the environmental chamber (1) are equipped with lifting rings (103), which is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com