Remote temperature monitoring system for glass tempering furnace

A glass tempering and monitoring system technology, used in temperature control using digital devices, temperature control, temperature control using electric methods, etc. problems, to solve the problem of real-time transmission of big data, convenient on-site layout, and stable data transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

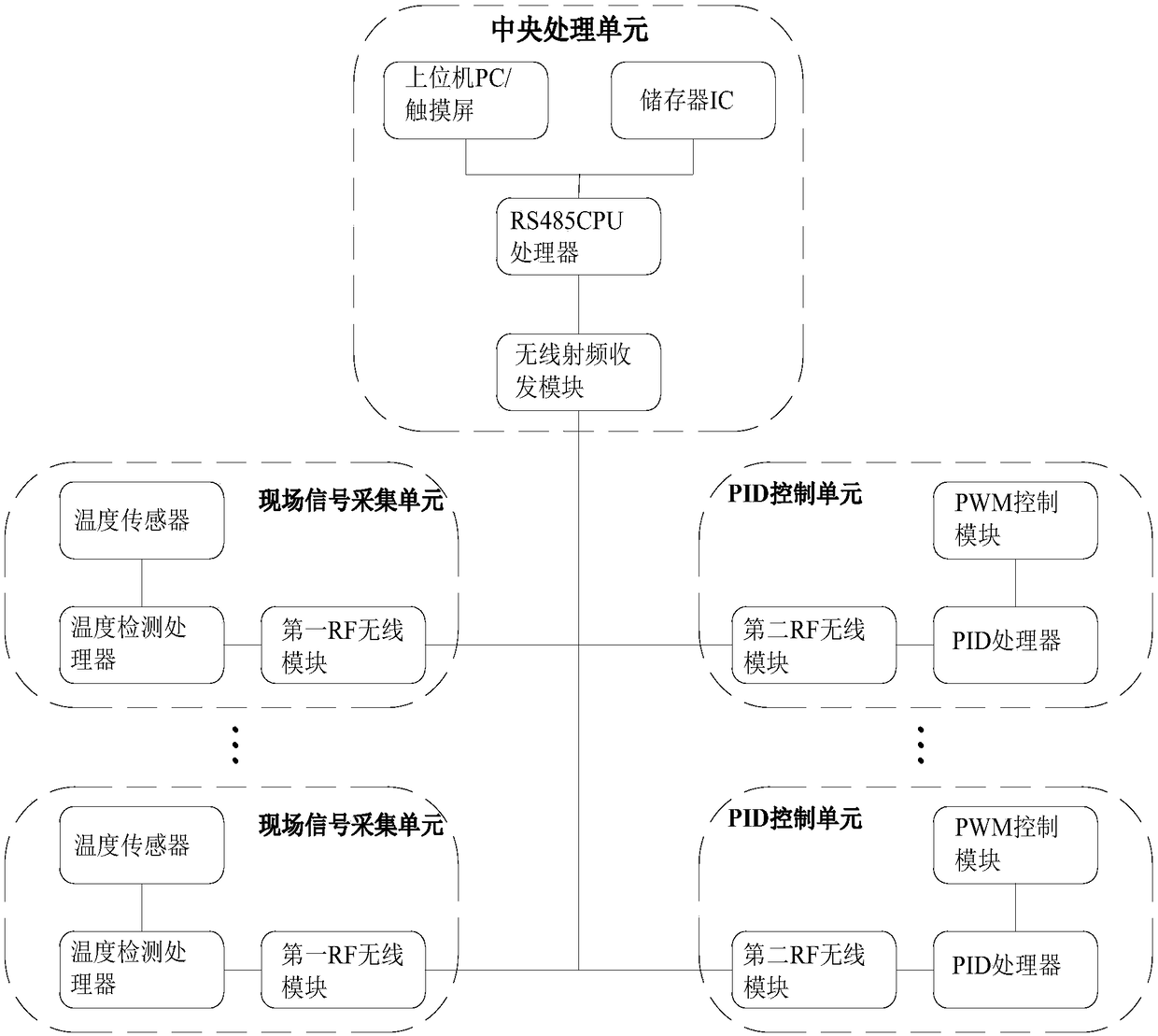

[0018] Embodiment 1: refer to figure 1 . A remote temperature monitoring system for a glass tempering furnace, including a central processing unit, several on-site signal acquisition units, and several PID control units;

[0019] The central processing unit includes a RS485CPU processor and an upper computer PC / touch screen electrically connected with the RS485CPU processor, a wireless radio frequency transceiver module, and a memory IC;

[0020] The upper computer PC / touch screen is equipped with 6 sets of digital tube displays, and provides corresponding button settings. Even if there is no upper computer, system settings can also be performed, which is convenient for human intervention, viewing of fault codes, and maintenance;

[0021] Each on-site signal acquisition unit includes a temperature sensor for collecting temperature signals in the furnace body, a temperature detection processor, a first RF wireless module, and the temperature sensor and the first RF wireless mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com