A kind of fiber silk electrode material and preparation method thereof

A technology of electrode materials and fiber filaments, which is applied in the field of polymer functional materials preparation, can solve the problems of complex process, restricted popularization, environmental pollution, etc., and achieve the effect of simple process, good catalytic performance and low condition requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

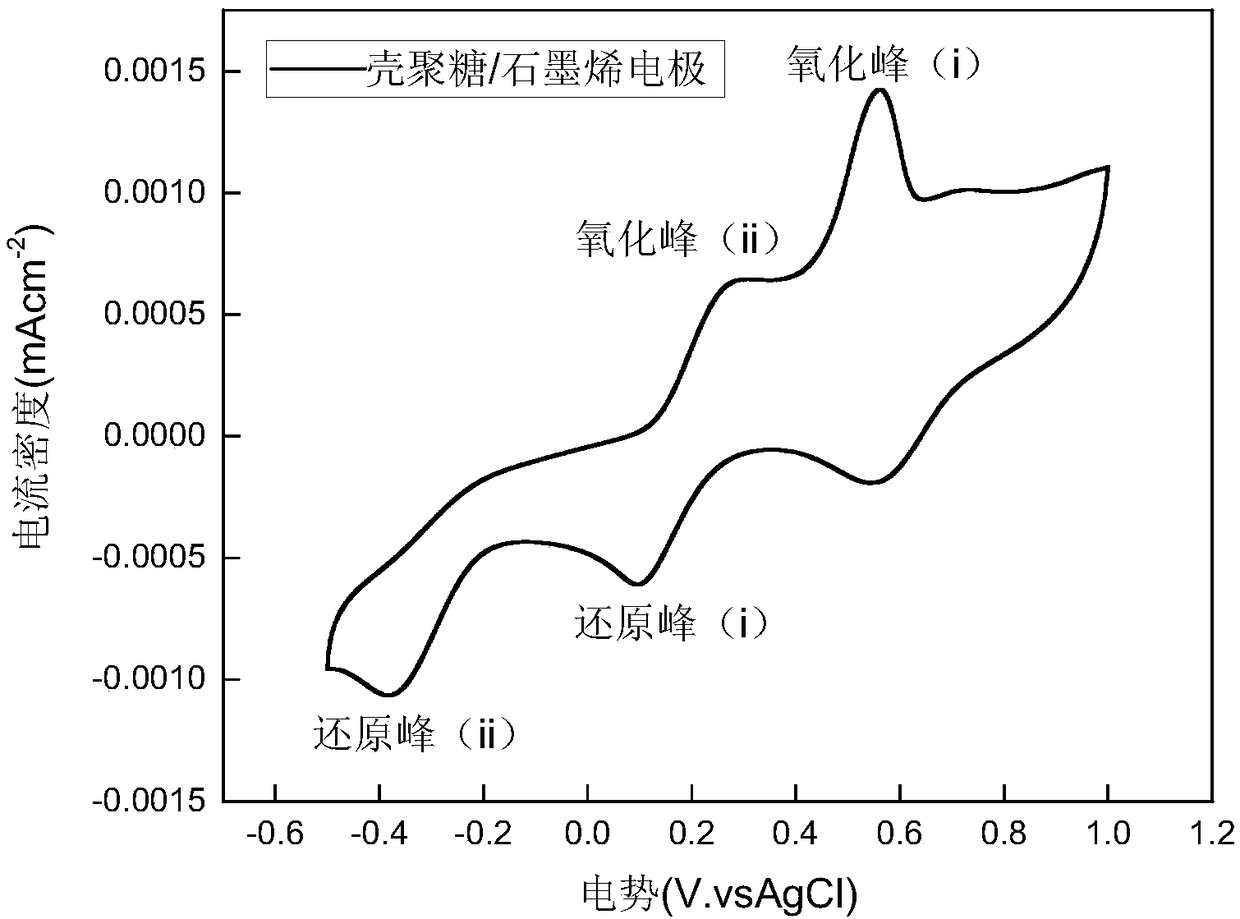

Embodiment 1

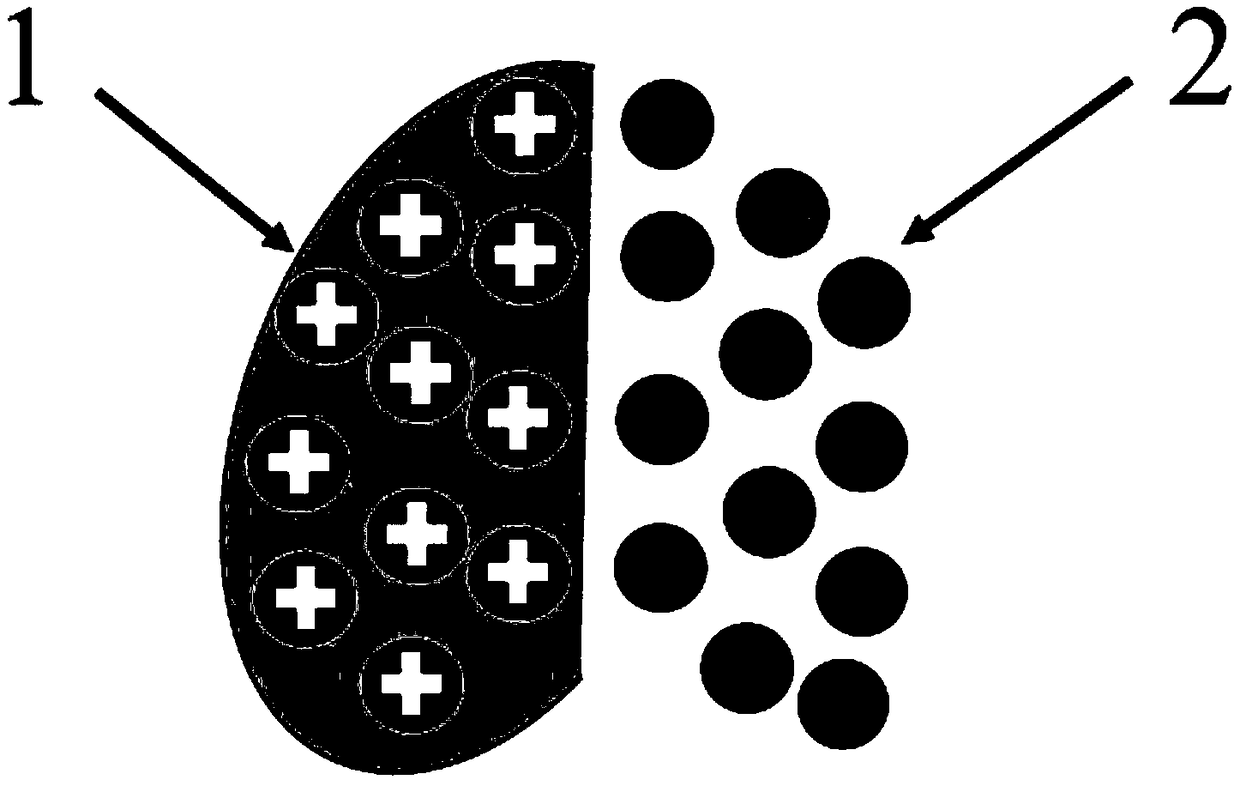

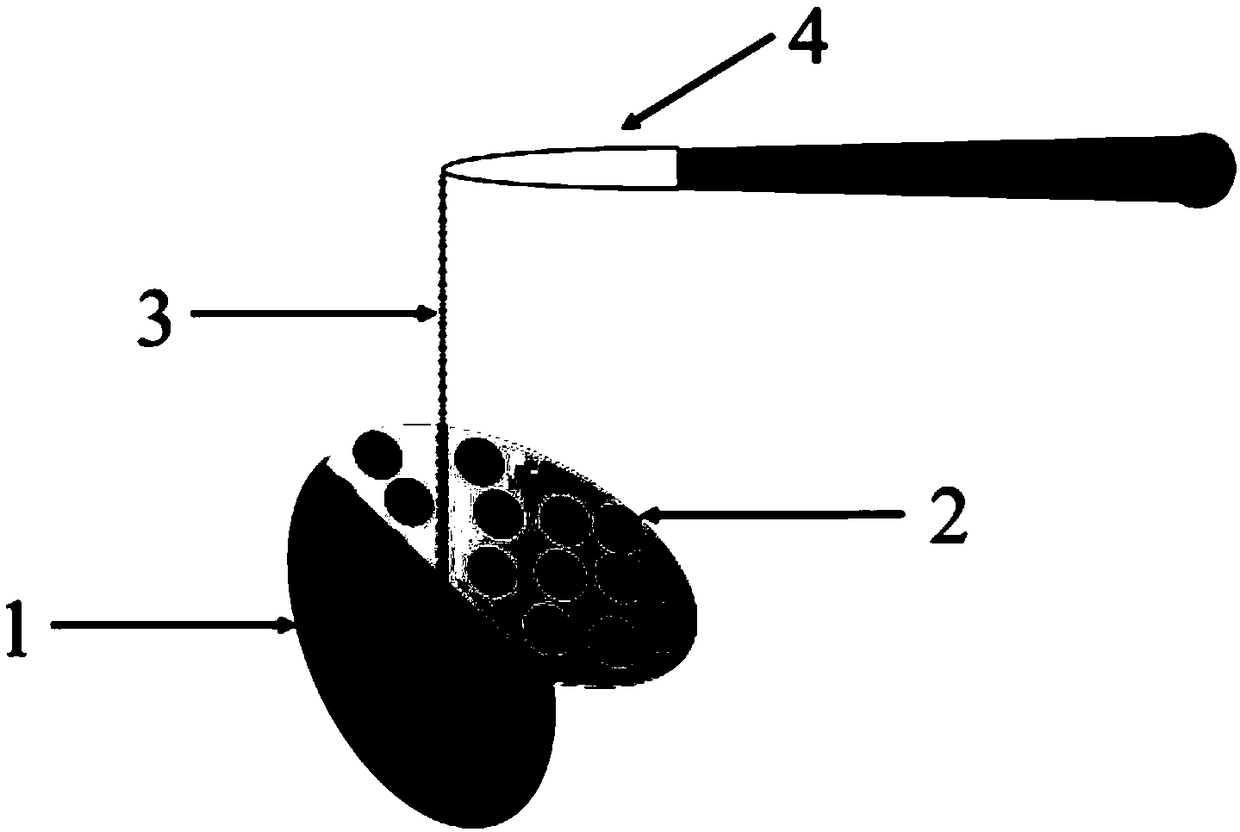

[0042] (1) Pipette 100mL of distilled water into a 250mL beaker, and drop into 3mL of glacial acetic acid solution, stir evenly; in the case of mechanical stirring, slowly add 1g of chitosan powder into the solution, and continue to 150 ~ 1700r min -1 Stir rapidly for 3h, and let stand for 24h to discharge the air bubbles in the slurry to obtain chitosan slurry A;

[0043] (2) Weighing 100 mg of graphite oxide into a 100 mL volumetric flask, and ultrasonicating for 2 h to obtain a uniformly dispersed graphene oxide solution, and obtain solution A;

[0044] (3) Pipette 100mL of the solution A obtained in step (2) into a 250mL beaker, slowly add 1g of sodium alginate powder under the condition of mechanical stirring, stir rapidly for 4h, and let stand for 12h to discharge the air bubbles in the slurry to obtain Graphene / sodium alginate slurry B;

[0045] (4) pipette a drop of slurry A on the surface of the glass plate with a rubber dropper;

[0046] (5) Pipette a drop of slurr...

Embodiment 2

[0051] (1) Pipette 100mL of distilled water into a 250mL beaker, drop into 3mL of glacial acetic acid solution, and stir evenly; under the condition of mechanical stirring, slowly add 5g of tetrabutylammonium bromide to the solution, and continue to use 150~1700r· min -1 Stir rapidly for 4h, and let stand for 18h to discharge the air bubbles in the slurry to obtain tetrabutylammonium bromide slurry A;

[0052] (2) Weigh 200mg of fullerene into a 100mL volumetric flask, and sonicate for 4 hours to obtain a uniformly dispersed fullerene solution, and obtain solution A;

[0053] (3) Pipette 100mL of the solution A obtained in step (2) into a 250mL beaker, slowly add 5g of sodium alginate powder under the condition of mechanical stirring, stir rapidly for 4h, and let stand for 24h to discharge the air bubbles in the slurry to obtain Fullerene / sodium alginate slurry B;

[0054] (4) pipette a drop of slurry A on the surface of the glass plate with a rubber dropper;

[0055] (5) P...

Embodiment 3

[0059] (1) Pipette 100mL of distilled water into a 250mL beaker, drop into 3mL of glacial acetic acid solution, and stir evenly; under the condition of mechanical stirring, slowly add 8g of n-octyltrimethylammonium bromide powder into the solution, and continue to 150~1700 rpm -1 Stir rapidly for 4h, and let stand for 24h to discharge the air bubbles in the slurry to obtain n-octyltrimethylammonium bromide slurry A;

[0060] (2) Weigh 400 mg of multi-walled carbon nanotubes into a 100 mL volumetric flask, and sonicate for 6 hours to obtain a uniformly dispersed multi-walled carbon nanotube solution, and obtain solution A;

[0061] (3) Pipette 100mL of the solution A obtained in step (2) into a 250mL beaker, slowly add 8g of sodium alginate powder under the condition of mechanical stirring, stir rapidly for 4h, and let stand for 24h to discharge the air bubbles in the slurry to obtain Multi-walled carbon nanotubes / sodium alginate slurry B;

[0062] (4) pipette a drop of slurr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com