Perforation processing device and processing method for perforated processing waste of cornertube

A technology of processing device and processing method, which can be used in perforating tools, peeling devices, metal processing equipment, etc., to solve the problems of limited quantity, inability to apply, adhesion to the inside of lifting parts or pipes, etc., to achieve the effect of prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

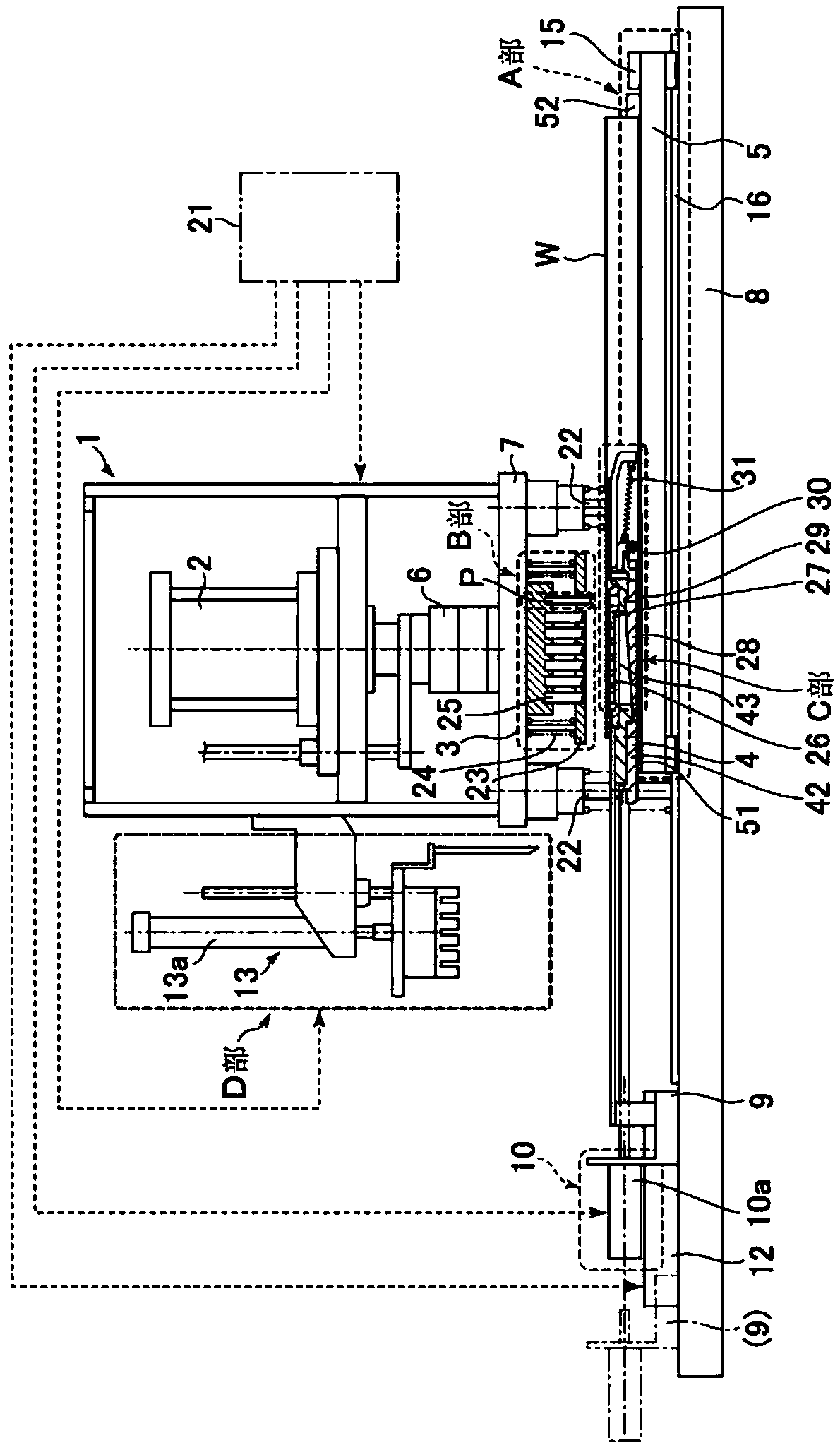

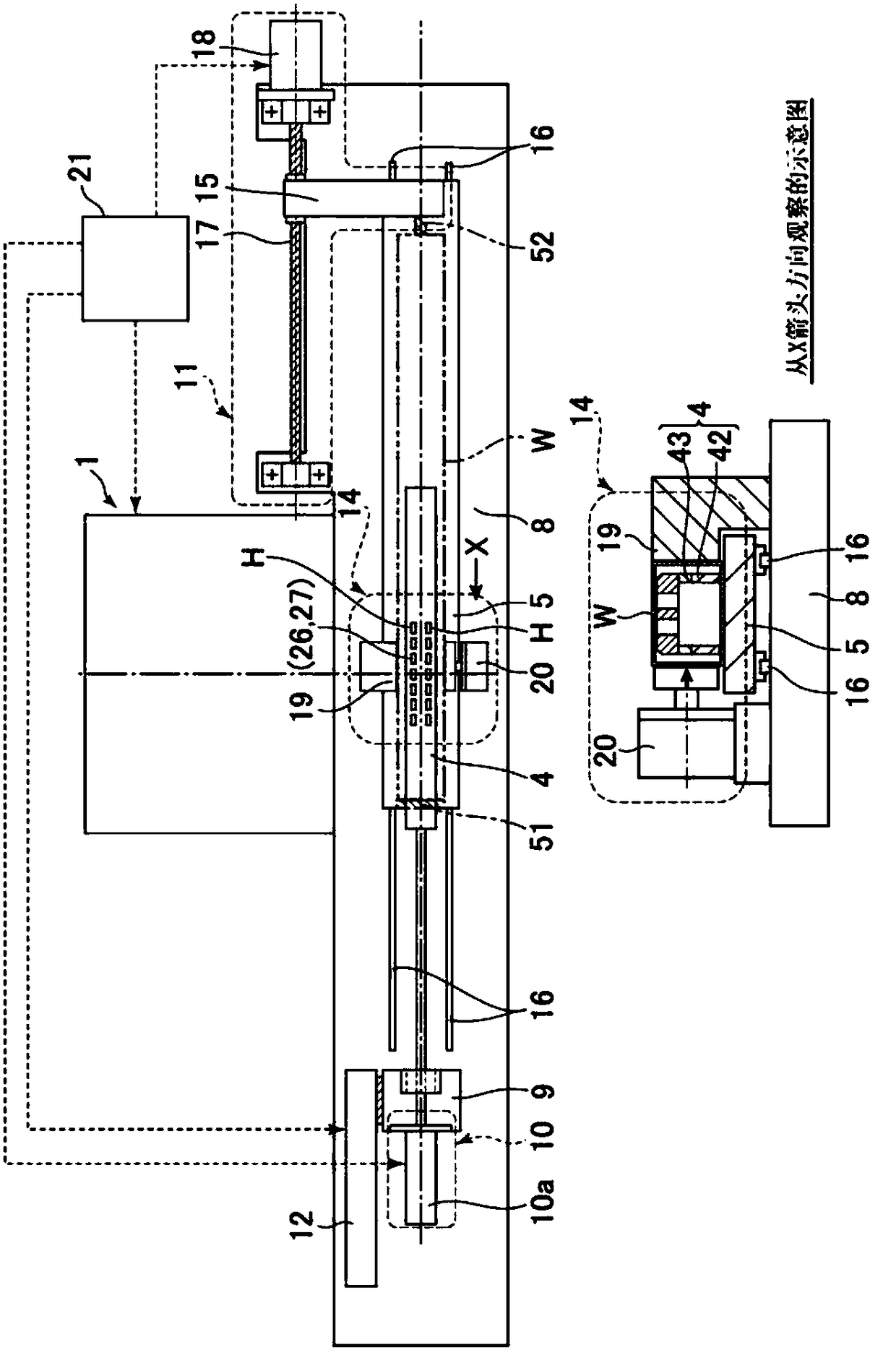

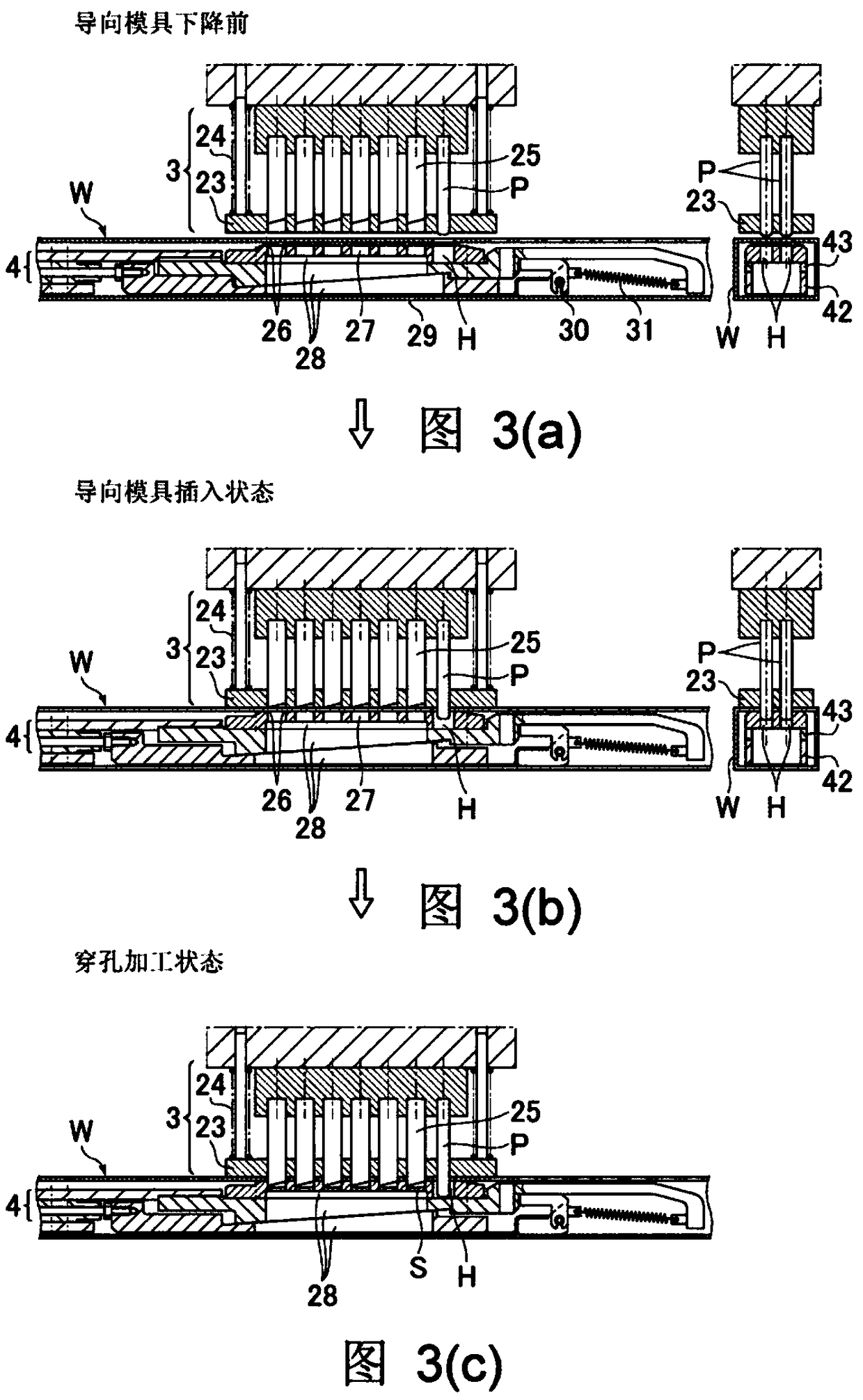

[0142] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0143] figure 1 It is an overall view (front view) of the perforating device of the first invention, and figure 2 It is an overall view (plan view) of the punching device of the first invention. Figure 3(a) ~ Figure 3(c) It is a schematic diagram of an outer mold device using a guide mold used in the piercing processing device of the first invention, Figure 4(a) ~ Figure 4(c) It is a schematic diagram of the expansion / reduction mechanism of the inner mold device used in the piercing processing device of the first invention, and Fig. 5 (a) and Fig. 5 (b) are waste recovery mechanisms of the inner mold device used in the piercing processing device of the first invention schematic diagram, Figure 6 It is an overall view (plan view) of a punching device according to another example of the first invention, Figure 7 It is an overall view (side view) of a punc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com